A kind of synthetic method of ts-1 titanium silicon molecular sieve

A titanium-silicon molecular sieve, TS-1 technology, which is applied in molecular sieve compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the high synthesis cost of TS-1 molecular sieve, large grain size of TS-1 molecular sieve, and the price of template agent Expensive and other problems, to achieve the effect of facilitating industrial application, reducing the content of non-skeleton titanium, and reducing the time of hydrothermal crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

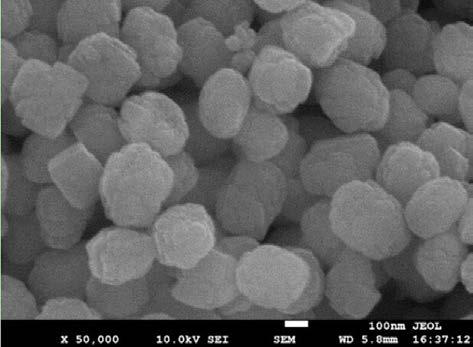

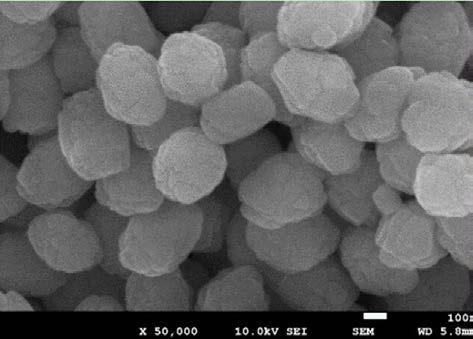

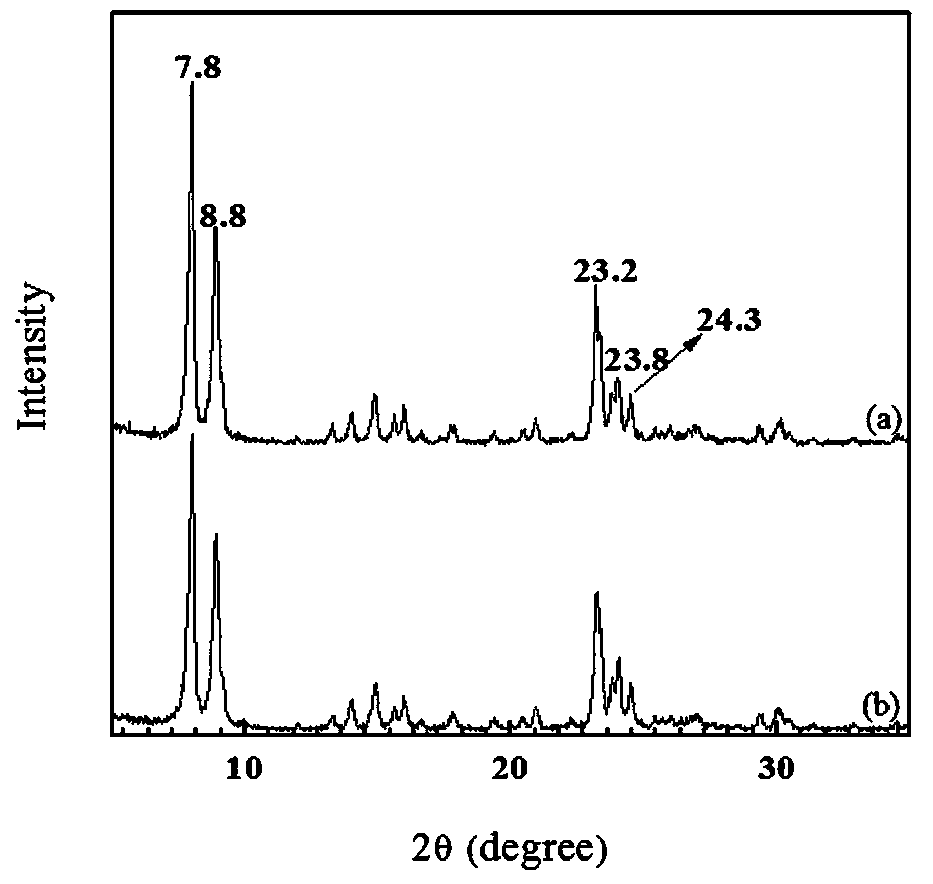

Image

Examples

Embodiment 1

[0032] (1) Preparation of precursor solution

[0033] Add the template agent to the silicon source, stir and hydrolyze at 25°C for 0.5h to obtain the mixed solution A; add the titanium source to the polyol at a molar ratio of 1:3, stir at 25°C for 0.5h to obtain the mixed solution B; , add the mixed solution B to the mixed solution A drop by drop. After the mixing is completed, gradually raise the temperature to 42°C and stir for 1 hour; raise the temperature again to 75°C, wash off the alcohol for 3 hours, and continue to replenish water to keep the liquid level unchanged; The mixed solution was transferred to a hydrothermal synthesis kettle for pre-crystallization at 110° C. for 24 hours, taken out and cooled to obtain a precursor solution. Among them, each material ratio (mole) silicon source SiO 2 : Titanium source TiO 2 : Templating agent: water is 1:0.100:0.30:20.

[0034] The silicon source is tetraethyl silicate, the titanium source is tetrabutyl titanate, and the p...

Embodiment 2

[0041] (1) Preparation of precursor solution

[0042] Add the template agent to the silicon source, stir and hydrolyze at 25°C for 1 hour to obtain the mixed solution A; add the titanium source to the polyol at a molar ratio of 1:5, and stir at 25°C for 0.5 hours to obtain the mixed solution B; Add the mixed solution B to the mixed solution A drop by drop. After mixing, gradually raise the temperature to 42°C, stir for 1 hour; raise the temperature again to 80°C, wash off the alcohol for 2 hours, and continue to replenish water to keep the liquid level unchanged; The solution was transferred to a hydrothermal synthesis kettle for pre-crystallization at 115°C for 22 hours, and cooled after taking it out to obtain a precursor solution. Among them, each material ratio (mole) silicon source SiO 2 : Titanium source TiO 2 : Templating agent: water is 1:0.125:0.40:20.

[0043]The silicon source is tetraethyl silicate, the titanium source is tetrabutyl titanate, and the polyhydric ...

Embodiment 3

[0050] (1) Preparation of precursor solution

[0051] Add the template agent to the silicon source, stir and hydrolyze at 25°C for 1 hour to obtain the mixed solution A; add the titanium source to the polyol at a molar ratio of 1:7, and stir at 25°C for 1 hour to obtain the mixed solution B; Add mixed solution B to mixed solution A drop by drop. After mixing, gradually raise the temperature to 45°C and stir for 0.5h; raise the temperature again to 80°C, wash off the alcohol for 2 hours, and continue to replenish water to keep the liquid level unchanged; The liquid was transferred to a hydrothermal synthesis kettle for pre-crystallization at 120° C. for 15 h, taken out and cooled to obtain a precursor liquid. Among them, each material ratio (mole) silicon source SiO 2 : Titanium source TiO 2 : Templating agent: water is 1:0.150:0.30:20.

[0052] The silicon source is tetraethyl silicate, the titanium source is tetrabutyl titanate, and the polyhydric alcohol is isopropanol. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com