Polymer resin composition

A resin composition and a polymeric technology, which is applied in the field of polymeric resin compositions, can solve problems such as insufficient coating or pattern transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

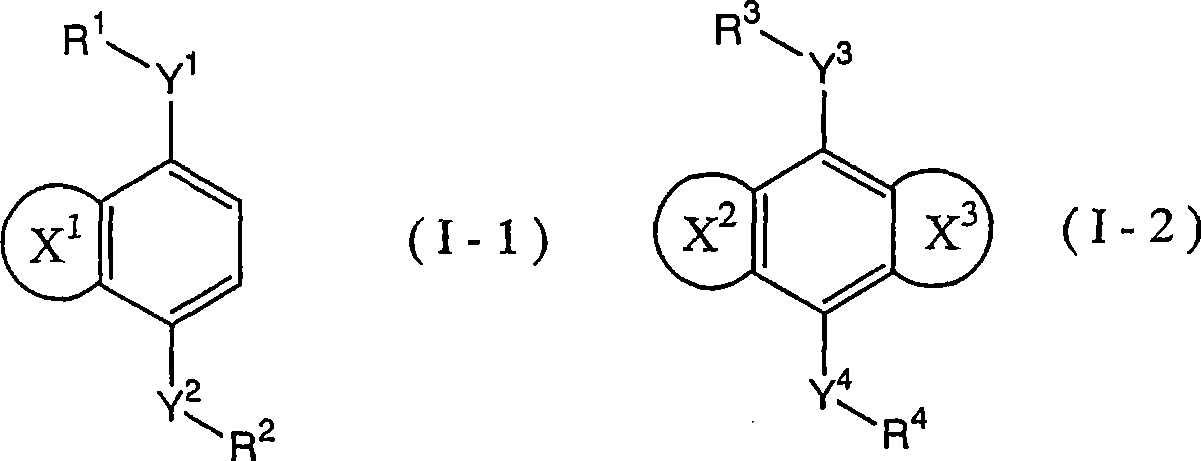

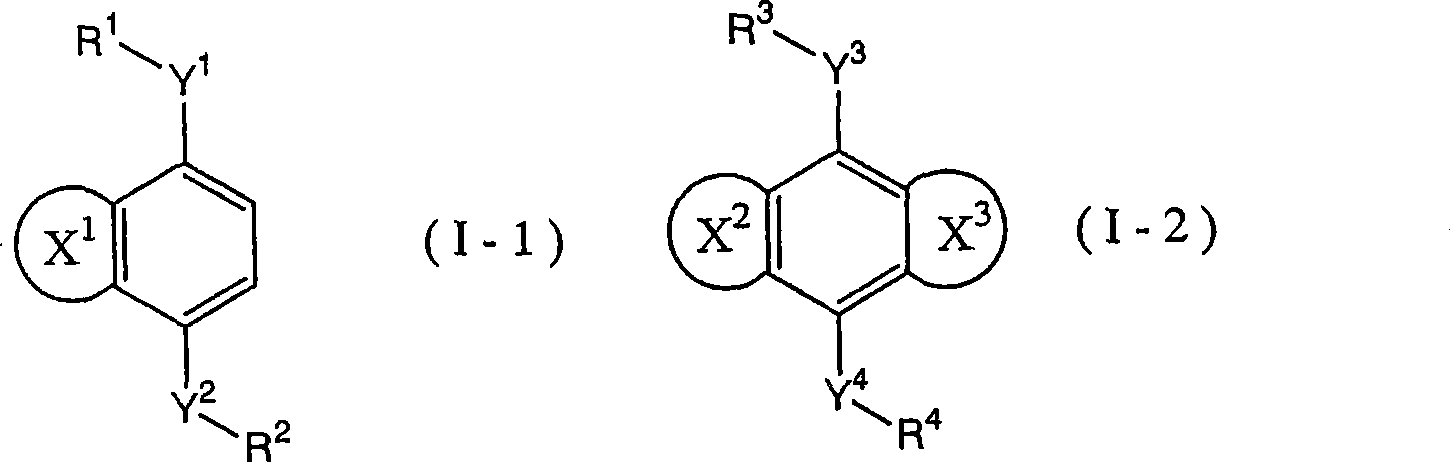

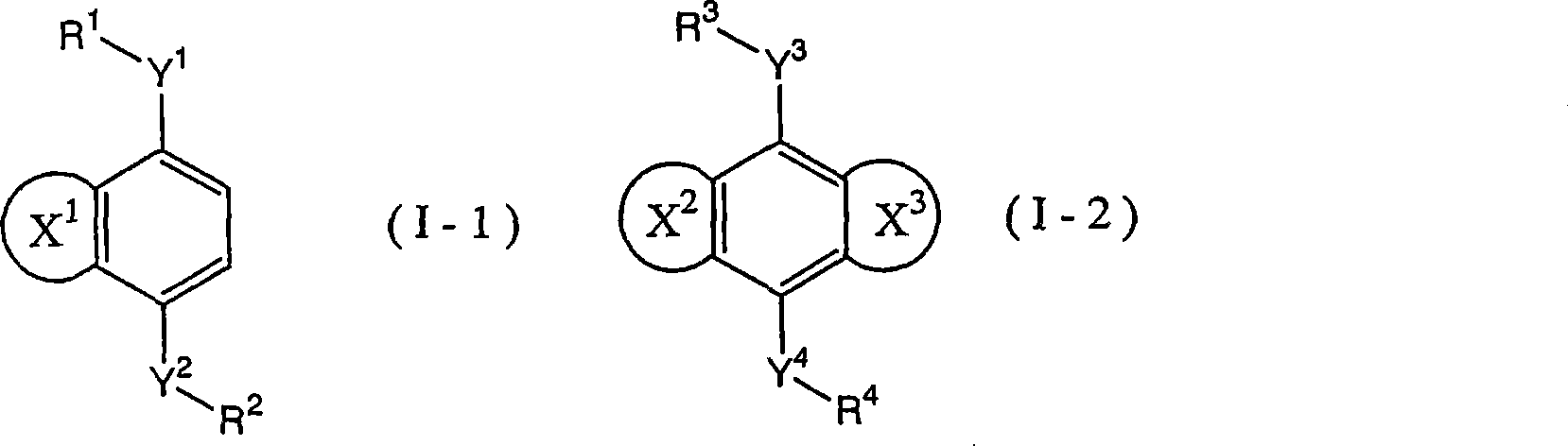

Method used

Image

Examples

Embodiment 1

[0232] [Synthesis of Polymeric Resin Composition 1]

[0233] Mix 153 parts of a solution of resin Aa (50 parts in terms of solid content), 50 parts of dipentaerythritol hexaacrylate (KAYARADDPHA; manufactured by Nippon Kayaku Co., Ltd.) (B), 4 parts of 2,2'-bis(2-chlorobenzene base)-4,4',5,5'-tetraphenyl-1,2'-diimidazole (B-CIM; manufactured by Hodogaya Chemical Co., Ltd.) (C), 1 part of 9,10-dibutyl Oxyanthracene (DBA; manufactured by Kawasaki Chemical Co., Ltd.) (D), 3 parts of pentaerythritol tetrathiopropionate (PEMP; manufactured by Sakai Chemical Industry Co., Ltd.) (T), 88 parts of 3-ethoxyethyl Propionate (D), 5 parts of 3-methoxy-1-butanol (D), and 65 parts of 3-methoxybutyl acetate (D), to obtain polymerizable resin composition 1.

[0234] [Creation of pattern 1]

[0235] A 2-inch square glass substrate (#1737; manufactured by Corning) was washed sequentially with a neutral detergent, water, and alcohol, followed by drying. On the glass substrate, at 200mJ / cm 2 T...

Embodiment 2

[0242] It carried out similarly to Example 1, it became the composition shown in Table 1, and the polymeric resin composition 2 and the pattern 2 were obtained.

Embodiment 3

[0244] It carried out similarly to Example 1, it became the composition shown in Table 1, and the polymeric resin composition 3 and the pattern 3 were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com