Uplift pile loading test method and apparatus

A load test and pull-resistant pile technology, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of test pile damage, test data distortion, etc., to prolong the service life, the test method is simple, and the device structure is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

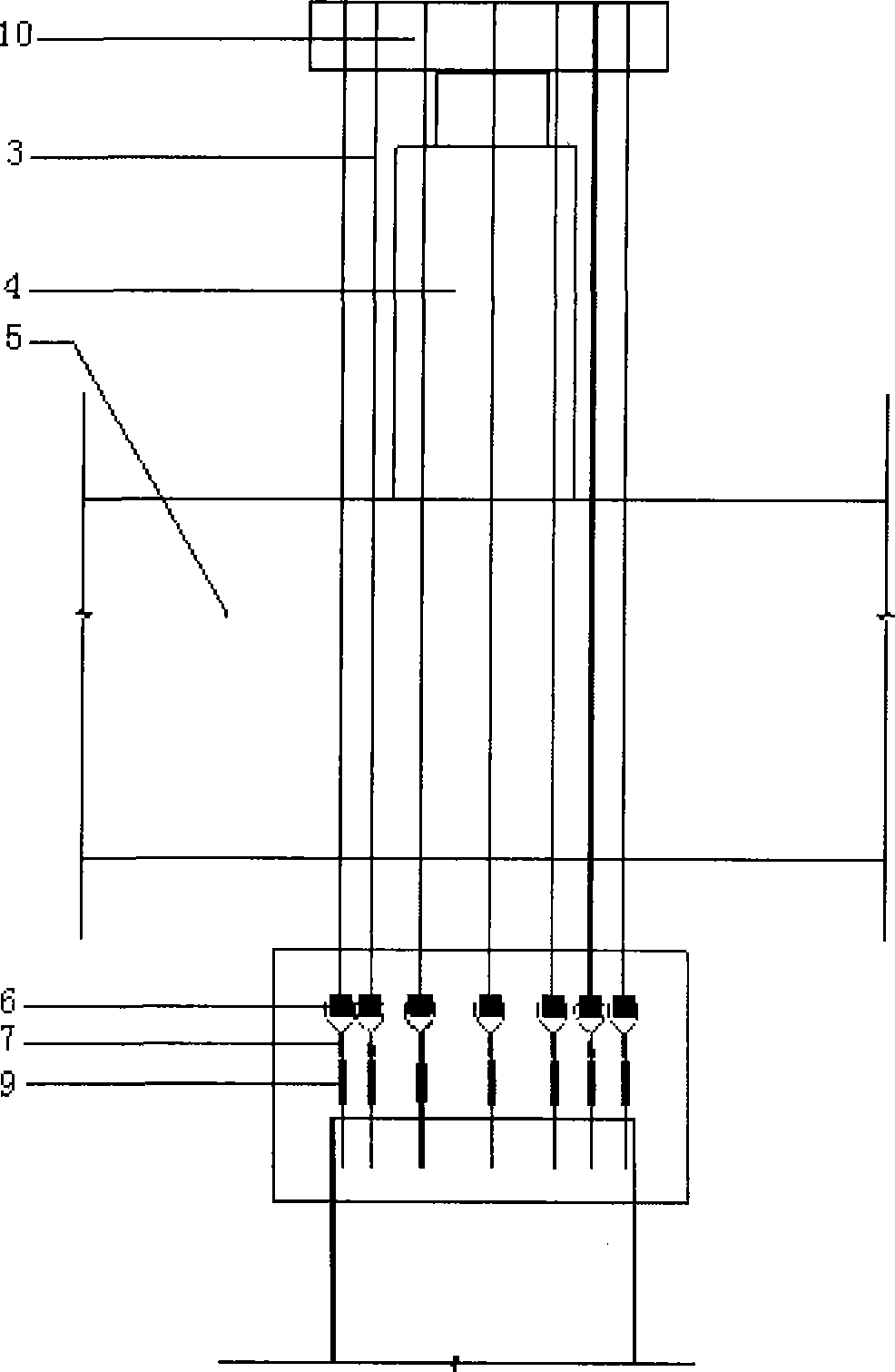

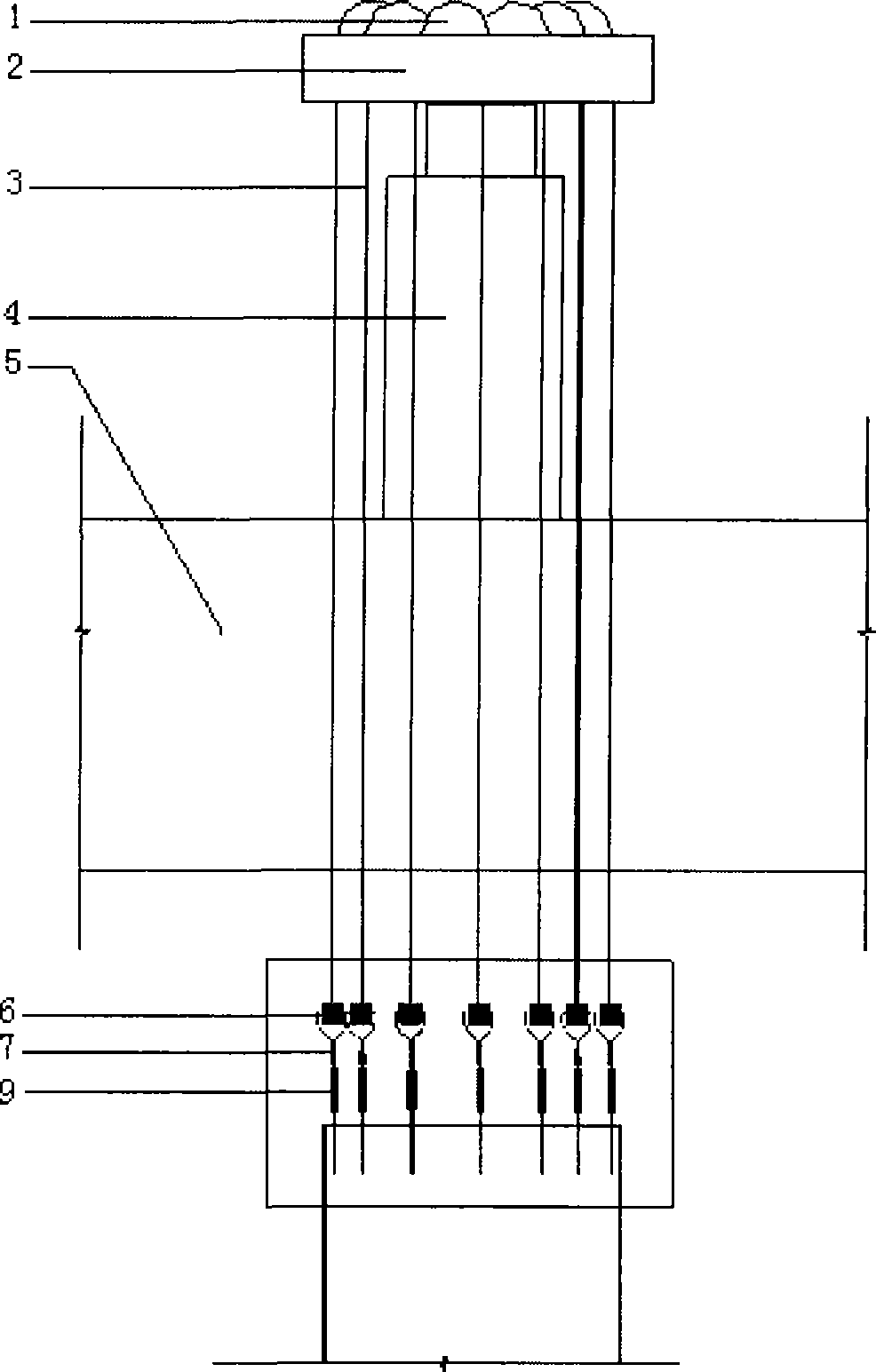

[0025] Embodiment 1: a kind of uplift pile load test method, comprises the following steps:

[0026] ①: Select the suitable test beam according to the uplift pile, and erect the test beam on the uplift pile;

[0027] ②: Place the jack on the test beam;

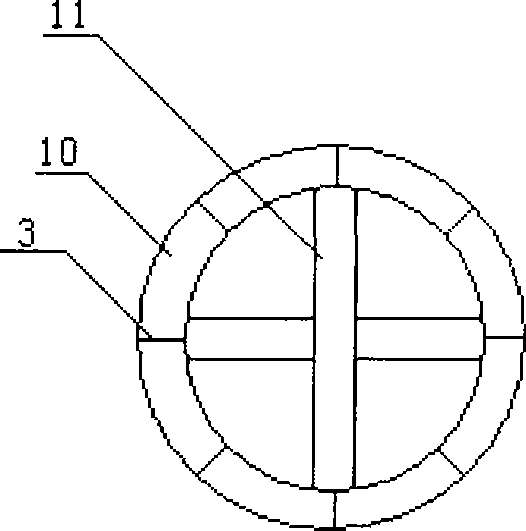

[0028] ③: Place an annular disc on the upper surface of the jack, set a bracket in the middle of the annular disc, and the upper surface of the jack is in contact with the bracket;

[0029] ④: Pass a steel wire rope through the ring disc and the tension pulley, the wire rope passes symmetrically on the ring disc, fix the two ends of the wire rope, set the anchor rib on the shaft of the tension pulley, and weld the anchor rib to the steel bar of the uplift pile ;

[0030] ⑤: Operate the jack, the steel bar of the uplift pile begins to receive the uplift force evenly, and then under the action of the upward force of the jack, the uplift bar reaches the maximum load it can bear.

Embodiment 2

[0031] Embodiment 2: A kind of load test method of uplift pile, step ①, step ② and step ⑤ are the same as embodiment 1, and the force transmission device described in step ③ is a universal force transmission plate, and the universal force transmission plate is provided with a universal force transmission plate. Hole; Step ④ is to place a steel wire rope in the through hole of the universal power transmission disc and the pulley pulley, and the steel wire rope passes symmetrically on the universal power transmission disc, and then the two ends of the steel wire rope are fixed.

Embodiment 3

[0032] Embodiment 3: A kind of load test method of uplift pile, step 1., step 2., step 3. and step 5. are the same as embodiment 2, and step 4. is the same as embodiment 2. In step 4., the steel wire rope and the universal force transmission disc are also connected. A semicircular tension wheel is placed, a groove is arranged on the tension wheel, and a steel wire rope is placed in the groove.

[0033] The above-mentioned uplift pile load test method, the preferred method is to set the anchorage on the anchorage bar, the anchorage bar and the steel bar of the uplift pile can be directly fixed together without welding, and the anchorage can be easily removed after the test.

[0034] The above-mentioned uplift pile load test method, the best practice is that the center point of the test beam in step ①, the center point of the upper surface of the jack in step ③, the center point of the force transmission device and the center point of the uplift pile are on the same axis In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com