Air cooling steam turbine steam discharge apparatus built-in with deoxidization apparatus

A steam turbine and steam exhaust technology, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problem of inappropriate location arrangement of oxygen removal device, complex structure and system of oxygen removal device, uneven contact between steam and water mist, etc. problems, to achieve the effect of small disturbance, simple structure and rapid heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

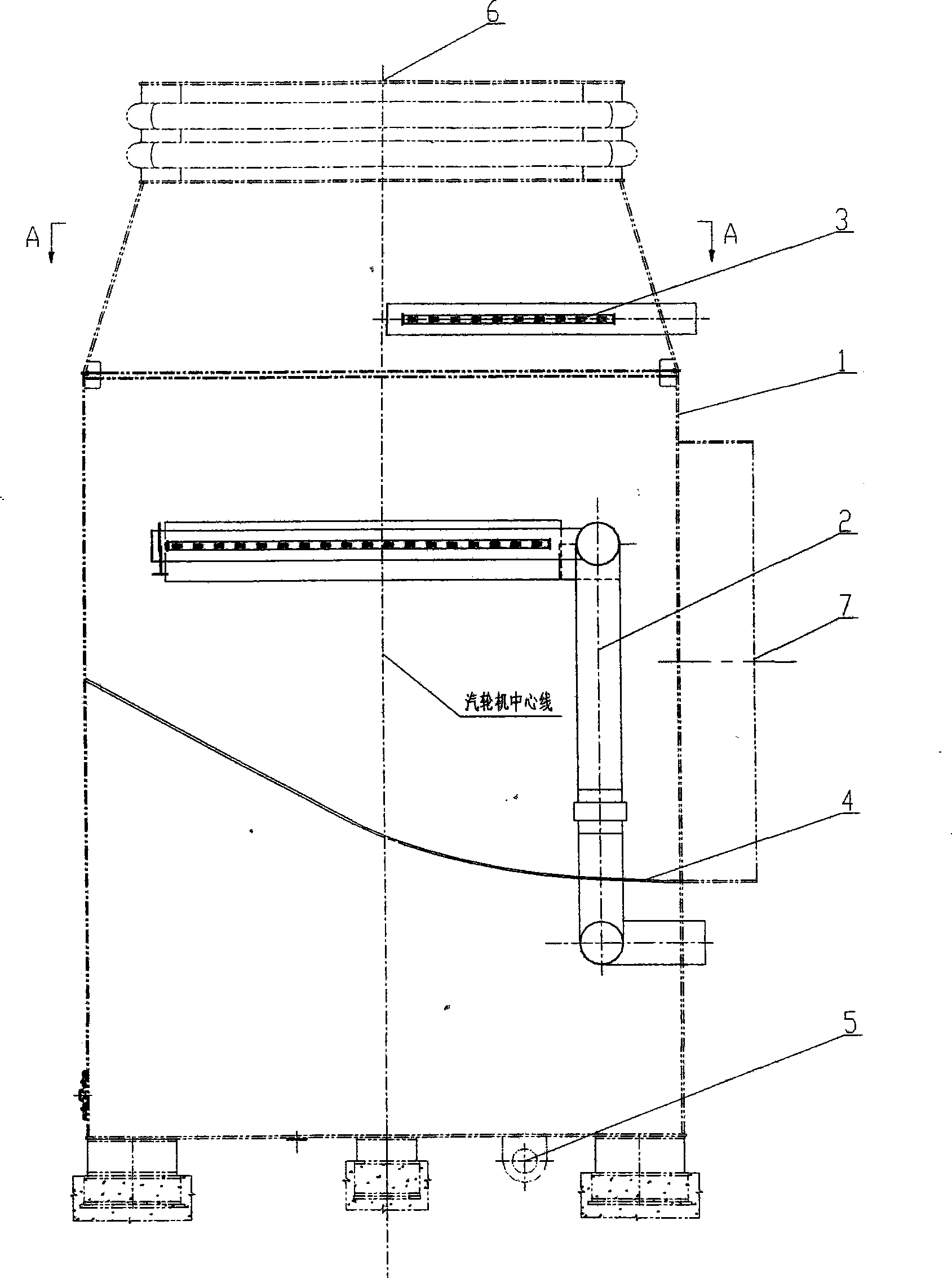

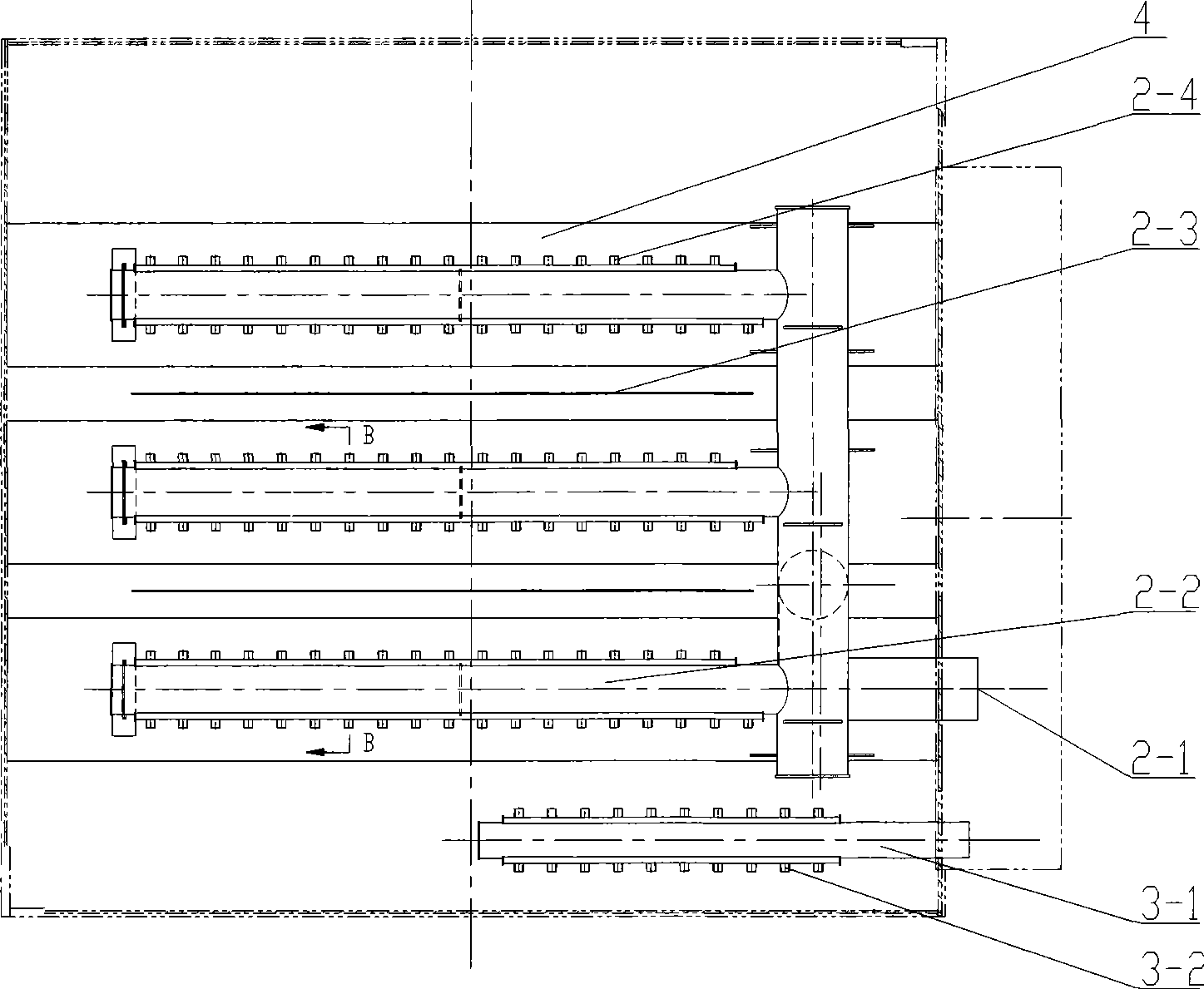

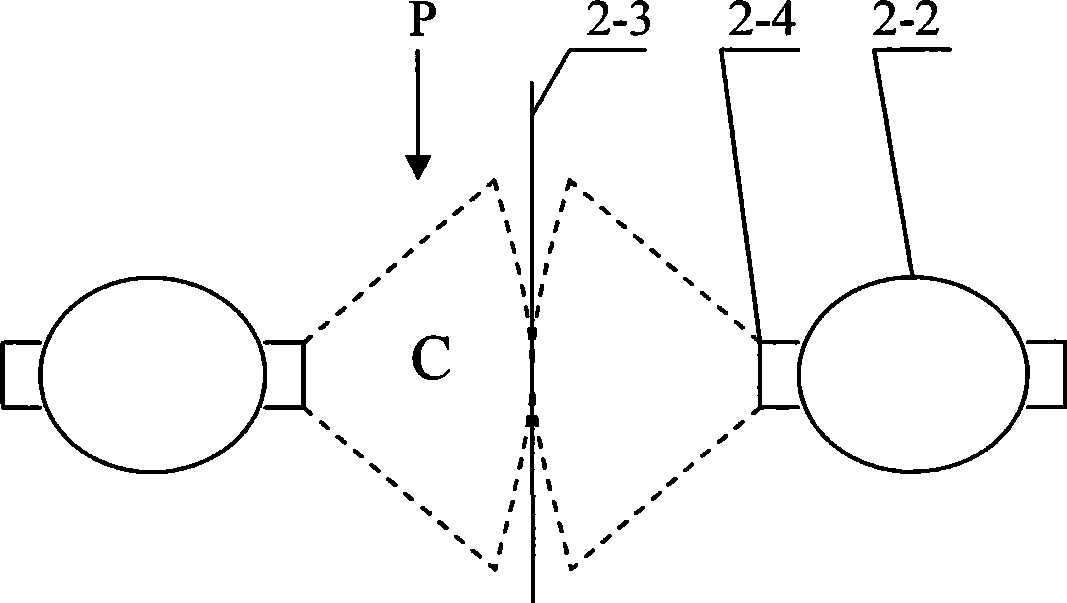

[0026] see Figure 1 to Figure 3 : This air-cooled steam turbine exhaust device with a built-in oxygen removal device includes an exhaust device 1, a condensed water deaeration device 2 and a water replenishment deaeration device 3 arranged in the exhaust device 1.

[0027] The steam exhaust device 1 is a box-shaped structure, the steam inlet 6 is set on the top wall of the box, the steam outlet 7 is set on the side wall of the box, and the lower part of the box has a water outlet 5; the box is equipped with a steam deflector 4 , located at the waist of the box and lower than the steam outlet 7, divides the inner space of the box into an upper chamber and a lower chamber, the upper chamber forms a steam channel, and the lower chamber forms a water collection tank. Condensed water deaeration device 2 and replenishment water deaeration device 3 are arranged in the upper chamber. There is a water passage on the deflector 4, and the heated and deoxidized water flows into the sump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com