Method and apparatus for photo-excitation of chemicals for atomic layer deposition of dielectric film

A technology for depositing gases and nitrides, which can be used in chemical instruments and methods, gaseous chemical plating, coatings, etc., and can solve problems such as troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

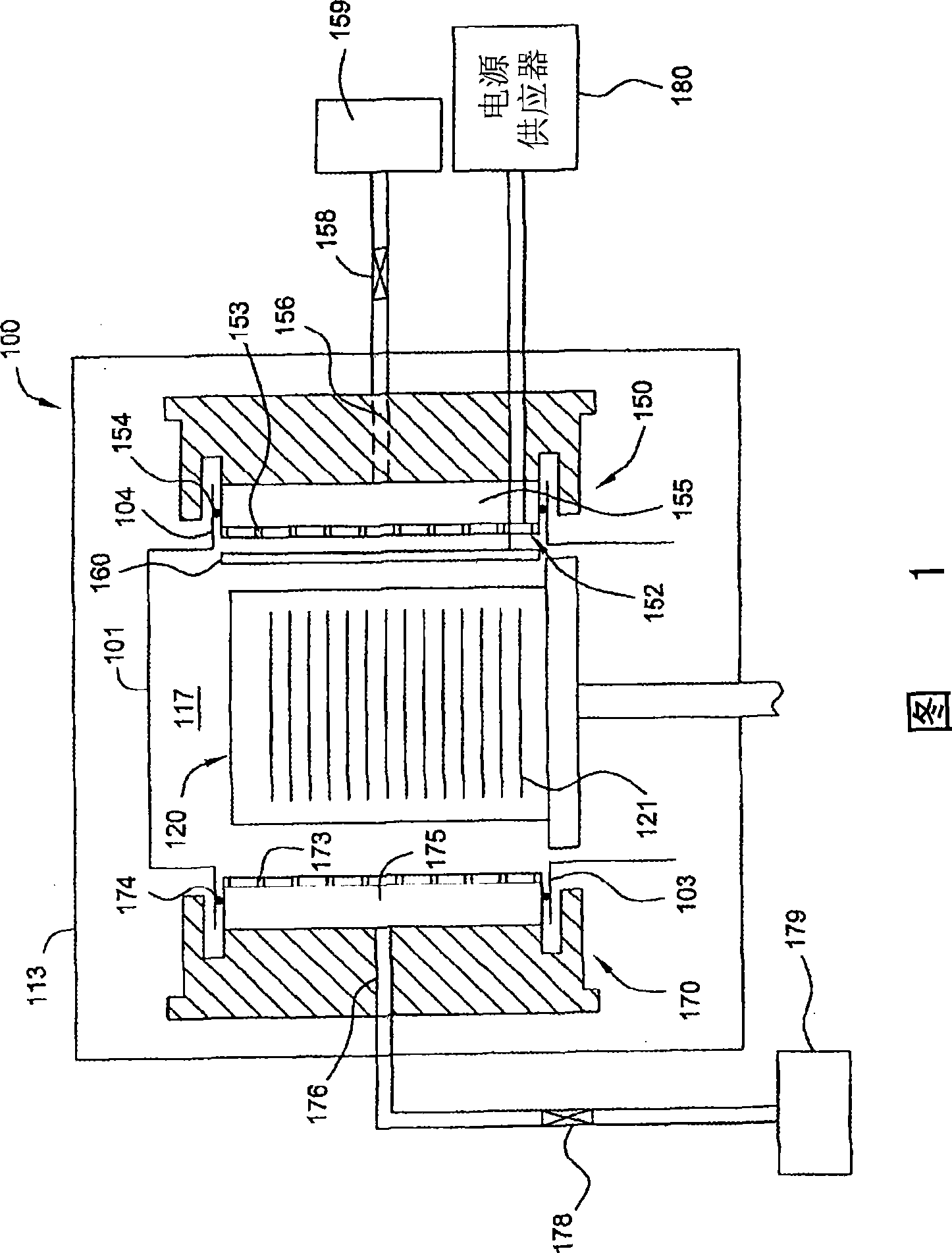

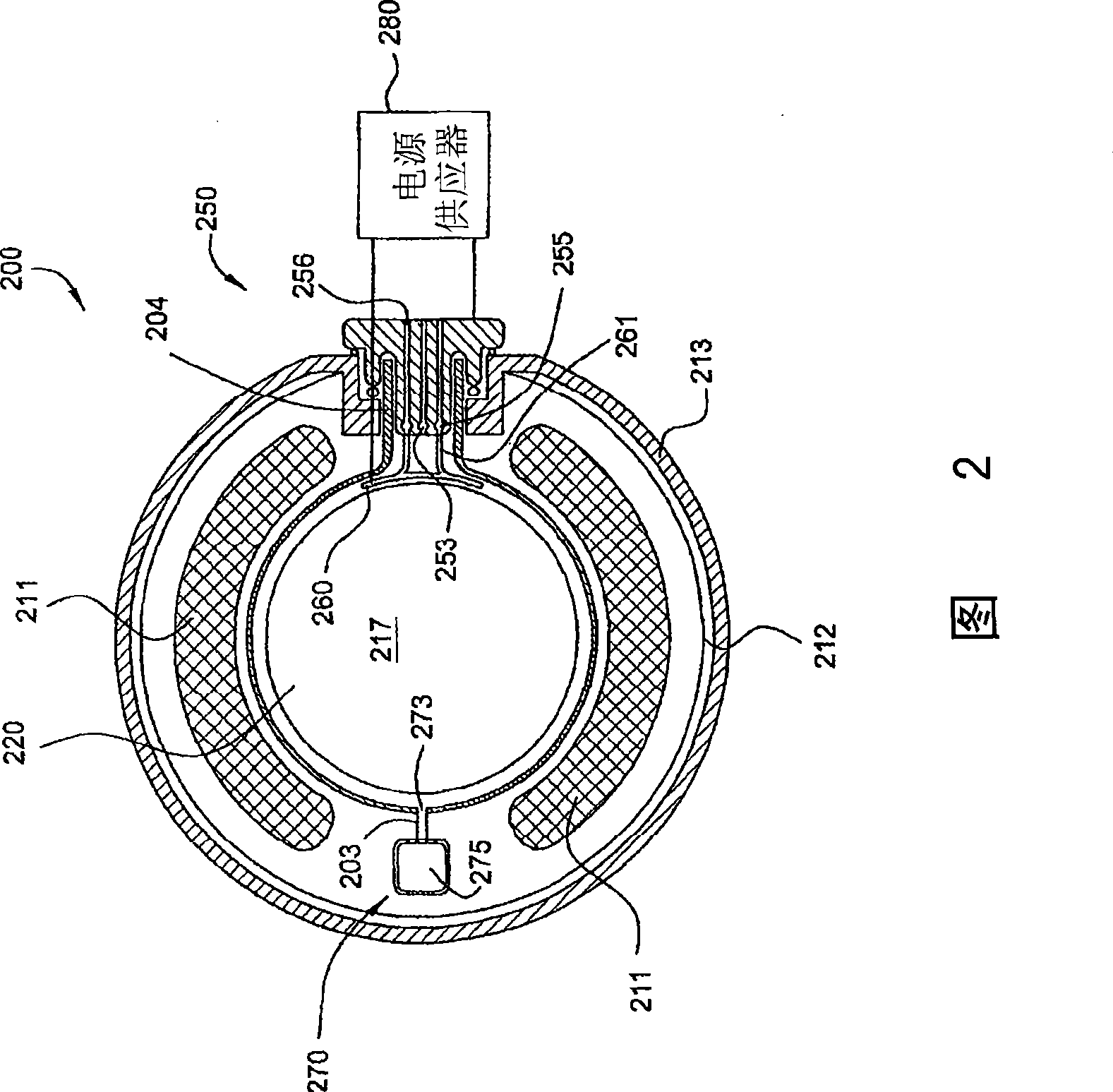

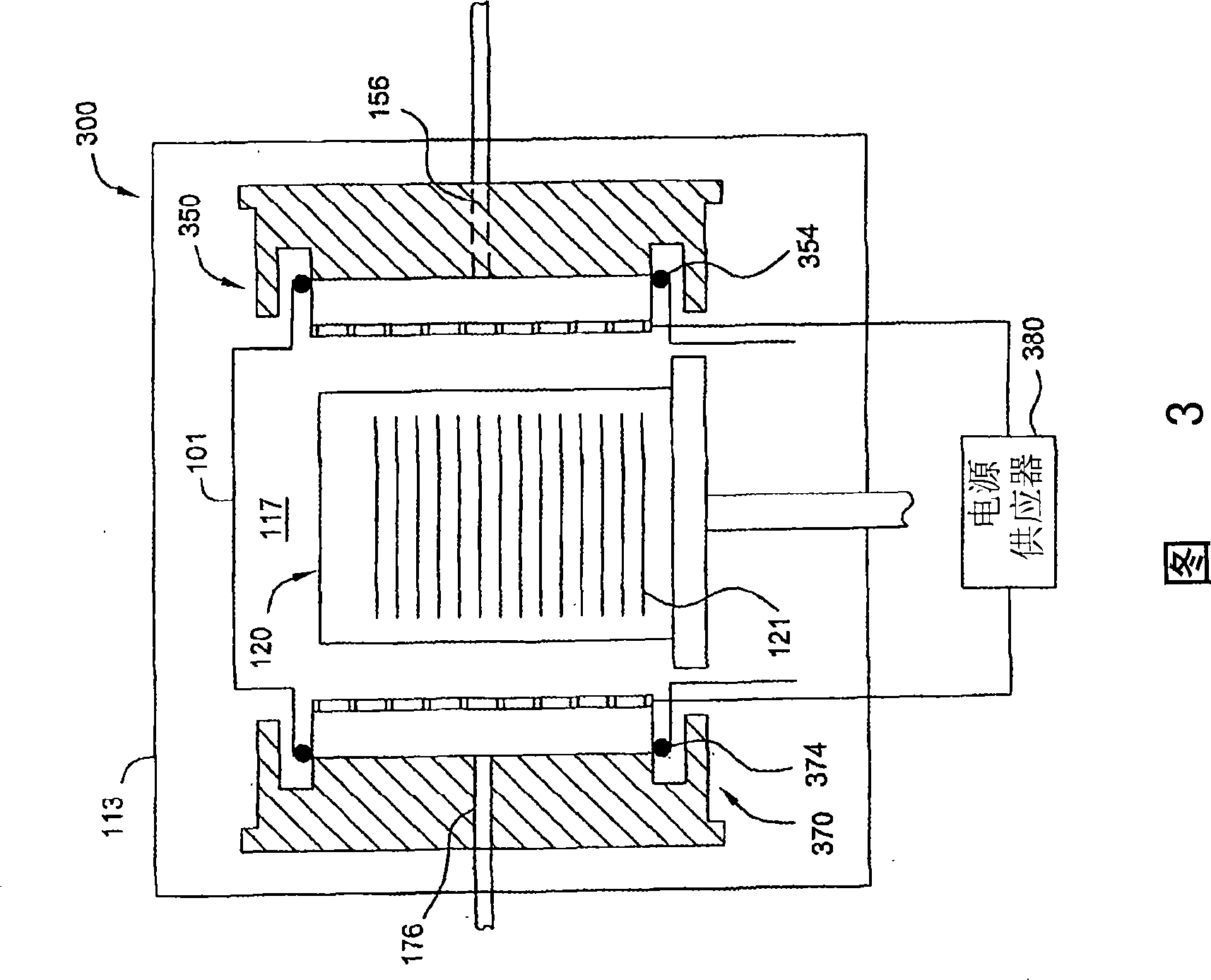

[0054] The present invention generally provides apparatus and methods for batch processing semiconductor substrates using components to aid in these processes by generating ions. In one embodiment of the present invention, a batch processing chamber having an excitation assembly disposed within the batch processing chamber enclosure is provided. An example of a batch processing chamber that can be used in an embodiment described herein is available as the FLEXSTAR system.

[0055] In general, excited species of process gases can be generated to aid in the ALD or CVD process as described herein. These species can be excited using plasma assist, UV assist (light assist), ion assist (eg, ions generated by an ion source), or combinations thereof. The species are excited within or adjacent to the processing region in the chamber enclosure to avoid recovery of the excited state before the ions reach the processing region of the batch processing chamber.

[0056] "Substrate" as u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com