Swing shearing device

A technology of shearing device and shearing mechanism, which is applied to shearing devices, accessories of shearing machines, shearing machine equipment, etc., can solve the problems of wasting plates and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

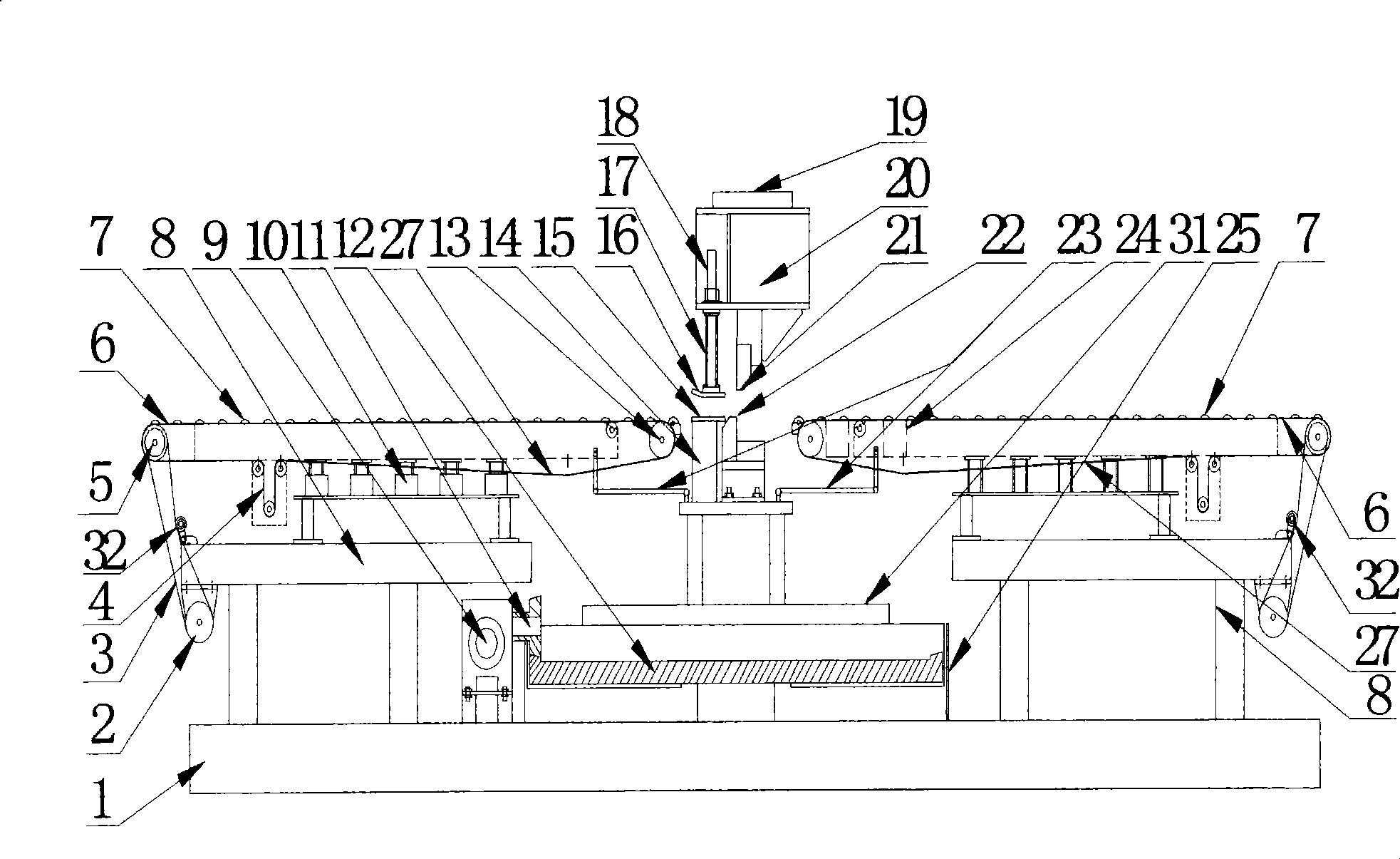

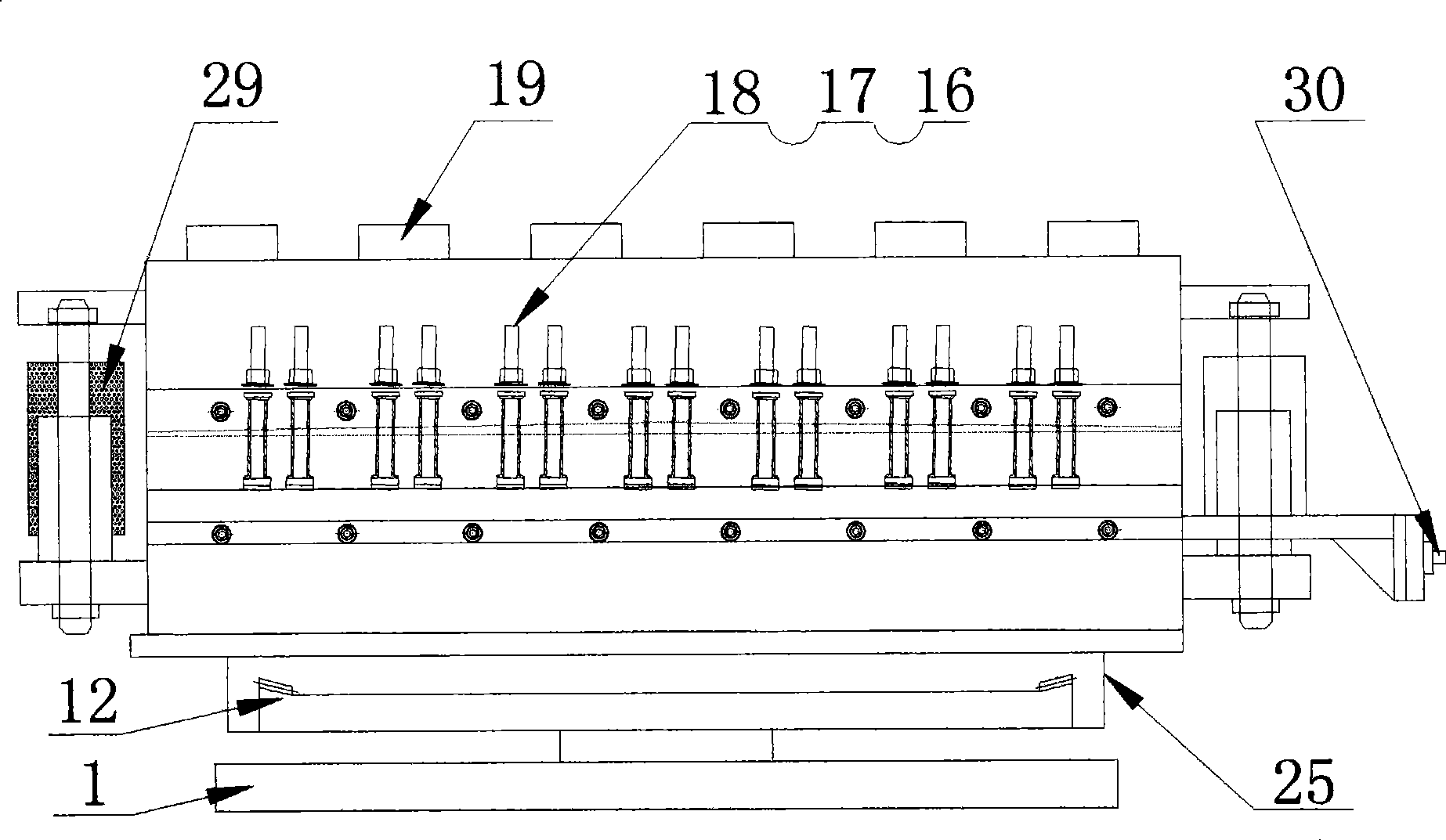

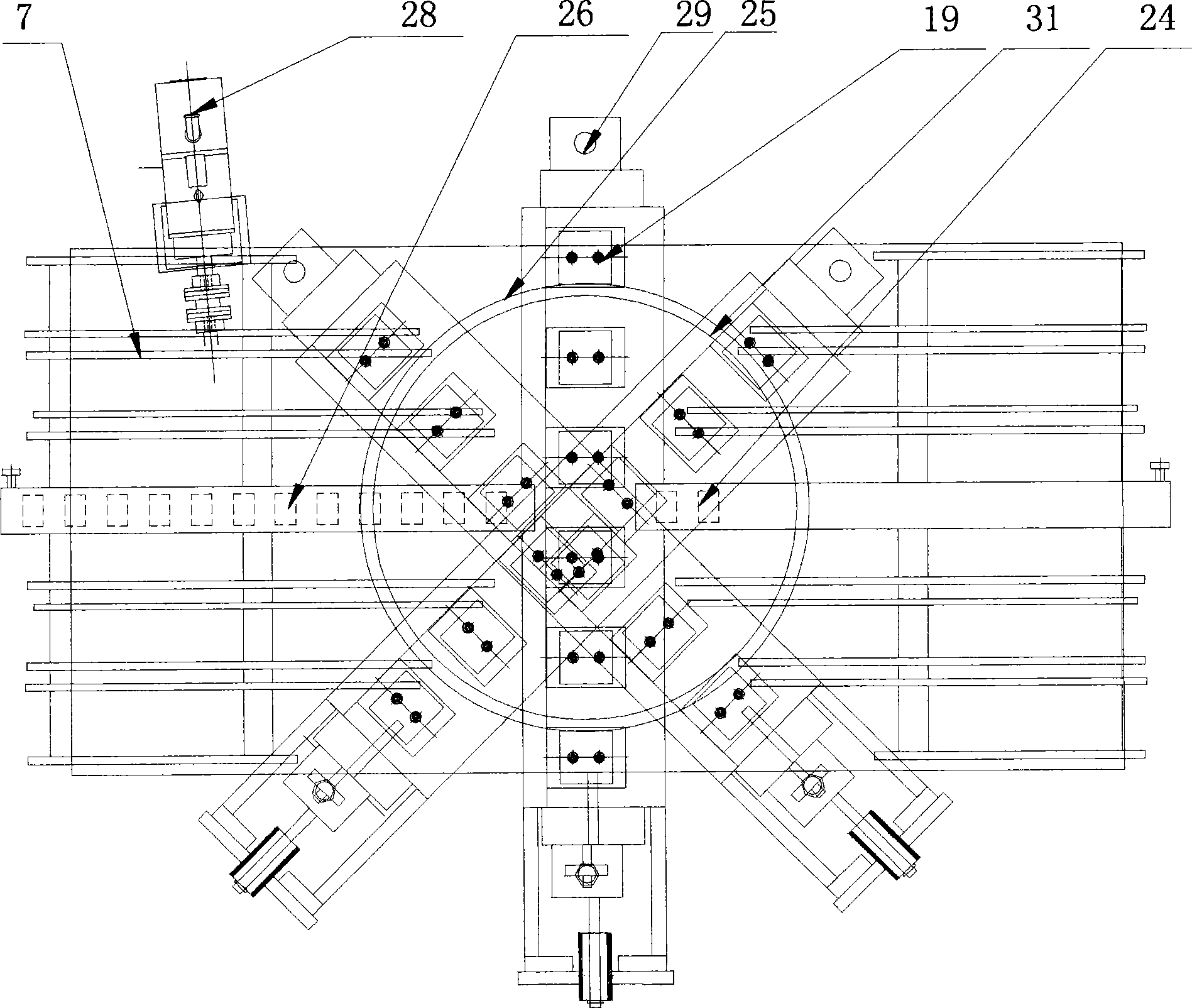

[0028] Such as figure 1 , 2 , As shown in 3, the swing shearing device is composed of four mechanisms, which can be divided into an entry-side transmission mechanism, a gear transmission mechanism, a shearing mechanism, and an exit-side transmission mechanism. The four parts are all installed on the base 1, and four T-shaped slots are opened on the base 1, and the base 1 and the workbench of the press are fixed by T-shaped bolts.

[0029] Such as figure 1 As shown, the gear transmission mechanism is decelerated by the servo motor 28 through the reduction box 9, and drives the driving bevel gear 11 to move. For perimeter protection. The top of the driven disc gear 12 is provided with supports for installing the upper and lower tool mounting brackets 14, 20, and the supports are fixed on the disc support 31 of the shearing mechanism, so that the overall shearing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com