Digging gangue concrete

A technology of concrete and gangue, applied in the field of concrete, to achieve the effects of low production cost, simple preparation process, and high cylinder compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

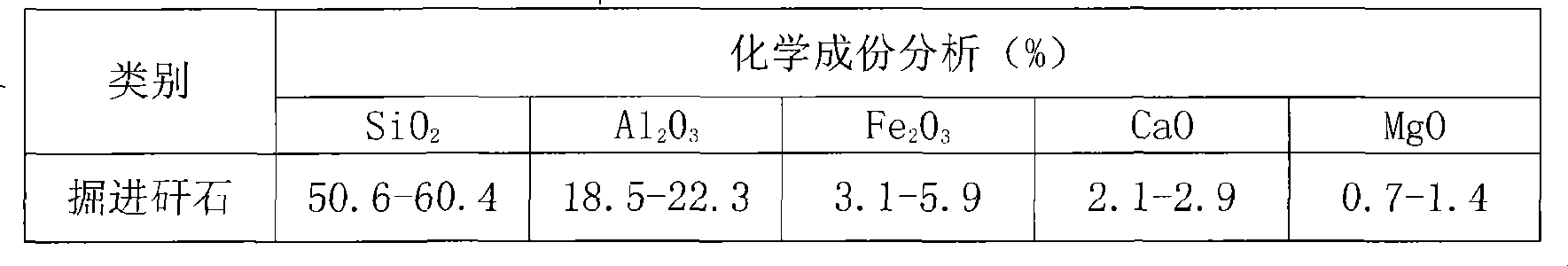

Image

Examples

example 1

[0026] Concrete with the label C10 prepared with excavation gangue coarse aggregate, the proportion of concrete material per cubic meter is: excavation gangue coarse aggregate 48%, P.0 32.5 cement 13%, medium sand 30%, water 9%; After mixing the above-mentioned mixture, put it into the mixer and stir for 3 minutes to prepare the tunnel gangue concrete.

[0027] Among them, graded excavation gangue coarse aggregate is selected, its particle size ranges from 5 to 31.5 mm, and the particle size distribution of coarse aggregate complies with the provisions of the national standard GB14685.

[0028] The water-cement ratio of the above-mentioned tunneling gangue concrete is W / C=0.69.

[0029] After on-site preparation according to the ratio of the above mixture, the average compressive strength after 28 days of curing is 13.2Mpa.

example 2

[0031] Concrete with the label C15 prepared with excavation gangue coarse aggregate, the proportion of concrete material per cubic meter is: excavation gangue coarse aggregate 48%, P.0 32.5 cement 15%, medium sand 30%, water 7%; After mixing the aforementioned mixture, put it into a mixer and stir for 4 minutes to prepare the tunneling gangue concrete.

[0032] Among them, graded excavation gangue coarse aggregate is selected, its particle size ranges from 5 to 31.5 mm, and the particle size distribution of coarse aggregate complies with the provisions of the national standard GB14685.

[0033] The water-cement ratio of the above-mentioned tunneling gangue concrete is W / C=0.47;

[0034] After on-site preparation according to the ratio of the above mixture, the average compressive strength after 28 days of curing is 16.8MPa.

example 3

[0036] Concrete with the label C20 prepared with excavation gangue coarse aggregate, the proportion of concrete material per cubic meter is: excavation gangue coarse aggregate 48%, P.0 32.5 cement 17%, medium sand 28%, water 7%; After mixing the aforementioned mixture, put it into a mixer and stir for 4 minutes to prepare the tunneling gangue concrete.

[0037] Among them, graded excavation gangue coarse aggregate is selected, its particle size ranges from 5 to 31.5 mm, and the particle size distribution of coarse aggregate complies with the provisions of the national standard GB14685.

[0038] The water-cement ratio of the above-mentioned tunneling gangue concrete is W / C=0.41.

[0039] After on-site preparation according to the ratio of the above mixture, the average compressive strength after 28 days of curing is 23.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com