Engine electric generator unit

A technology for generator sets and engines, which is applied in the cooling of engine components, machines/engines, and engines, can solve the problems of difficult heat dissipation of mufflers, and achieve the effects of simple structure, convenient movement and sufficient cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

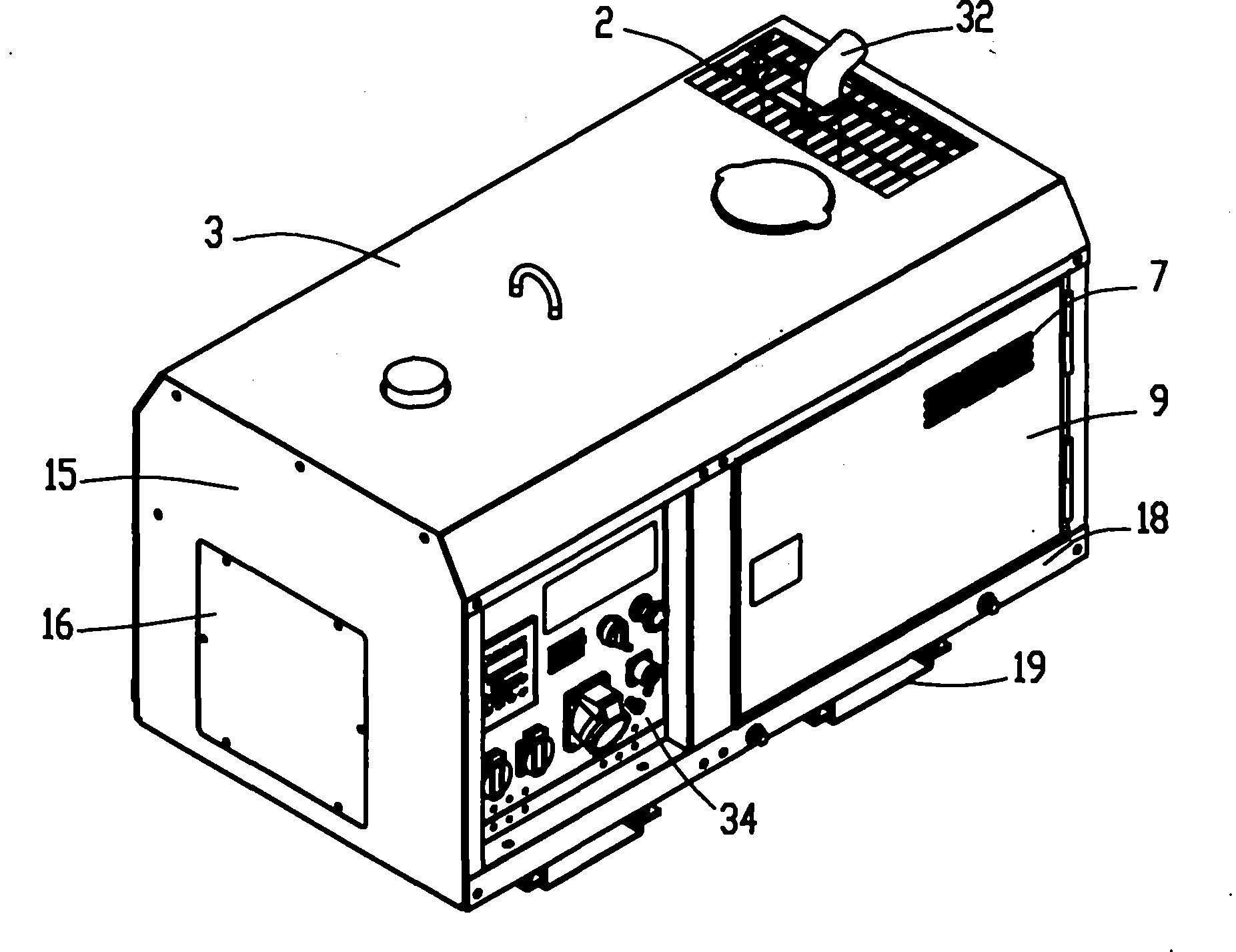

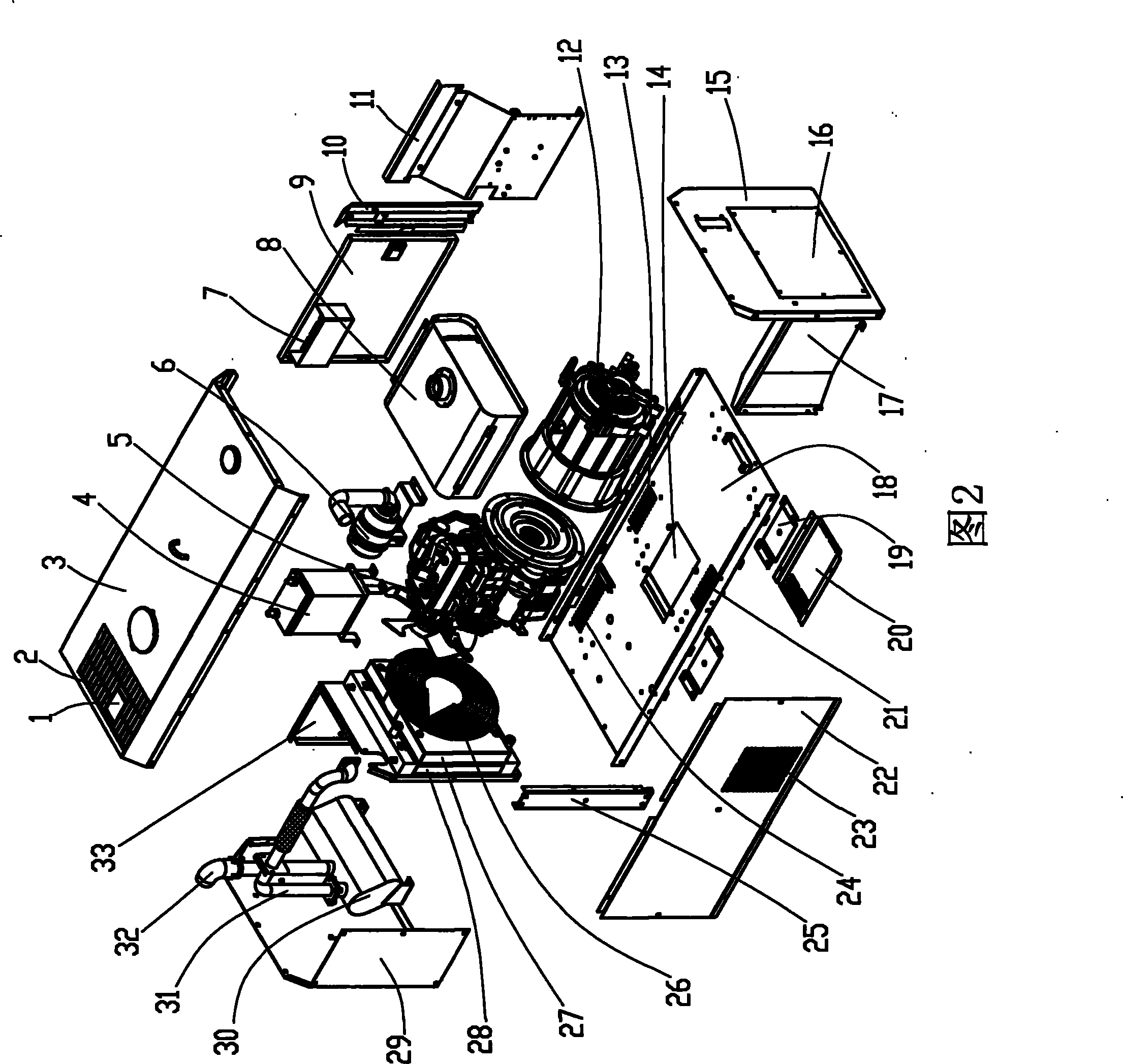

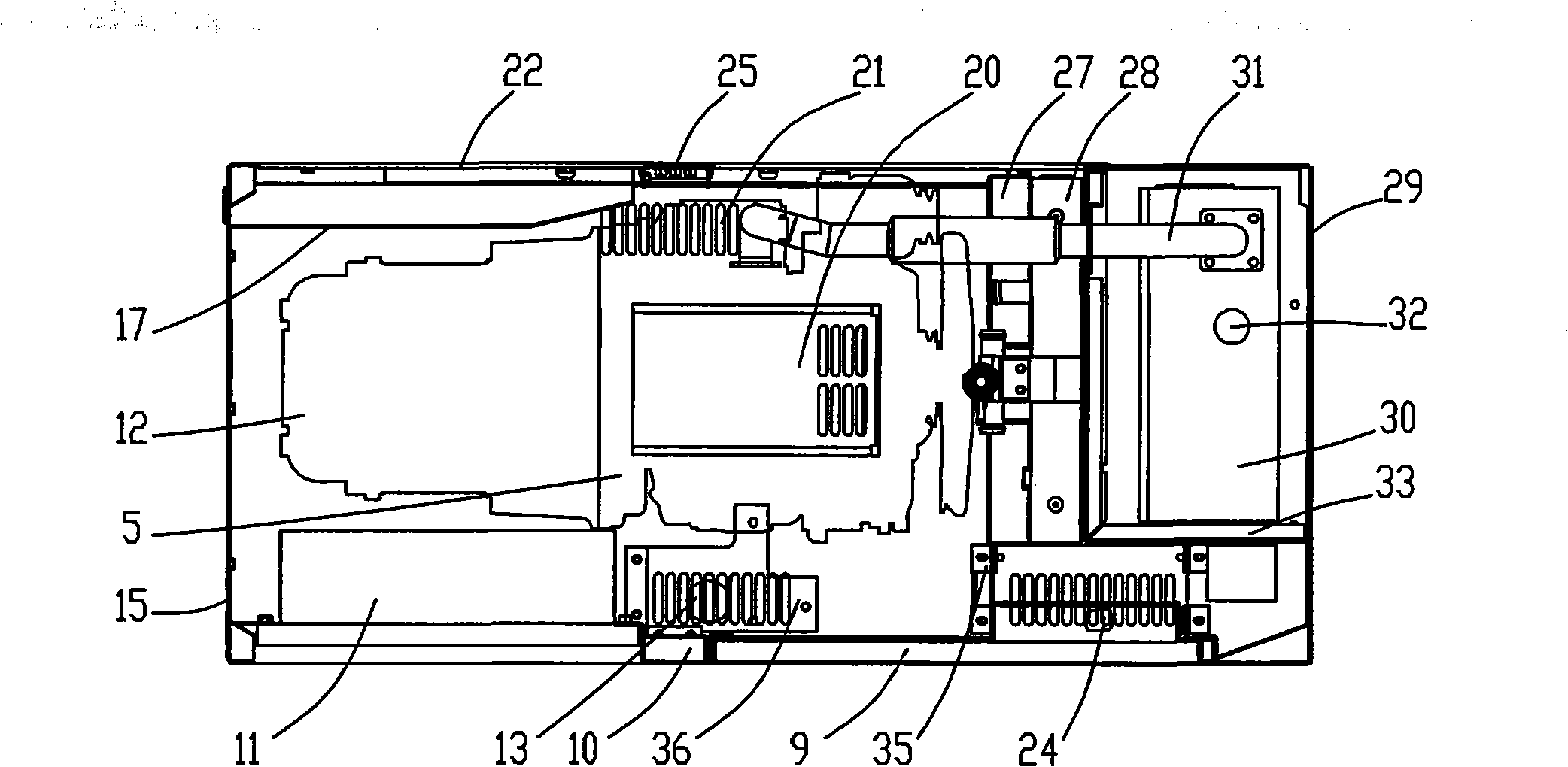

[0031] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0032] Figure 1 to Figure 14 As shown, it includes exhaust port 1, exhaust grille 2, top cover 3, battery 4, engine 5, air filter 6, door panel intake grille 7, fuel tank 8, door panel 9, front pillar 10, and rear panel Cover 11, generator 12, first air intake grille 13, air intake hole 14, right enclosure plate 15, right cover plate 16, air channel plate 17, chassis 18, backing plate 19, bottom plate air intake plate 20, second Air inlet grille 21, rear cover plate 22, rear cover air inlet grille 23, third air inlet grille 24, rear column 25, fan guard 26, water tank guard 27, radiator 28, left panel 29, Muffler 30, exhaust pipe 31, exhaust tail pipe 32, left partition 33, panel 34, battery support plate 35, air filter support plate 36, guard plate 37, support plate 38, bottom plate 39, rear reinforcement plate 40, rear Column mounting hole 41, bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com