Pressure exchanger

A technology of pressure exchanger and low pressure, which is applied in the direction of fluid pressure converter, machine/engine, mechanical equipment, etc. It can solve the problems of volumetric efficiency drop, large relative leakage rate, and difficult formation of pressure exchanger, so as to achieve the accuracy of convenient speed The effect of control, self-tightening seal with small leakage and high energy recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

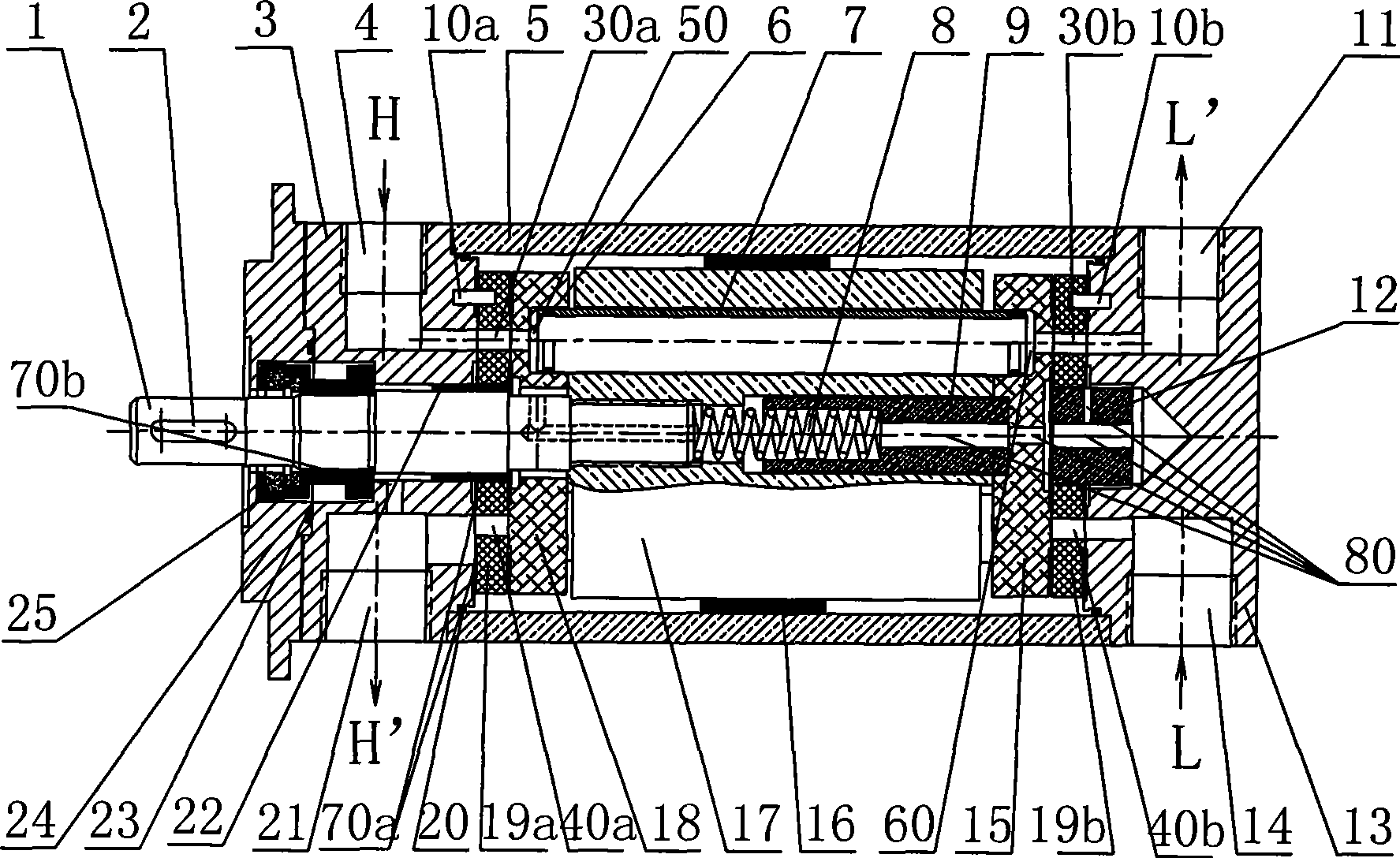

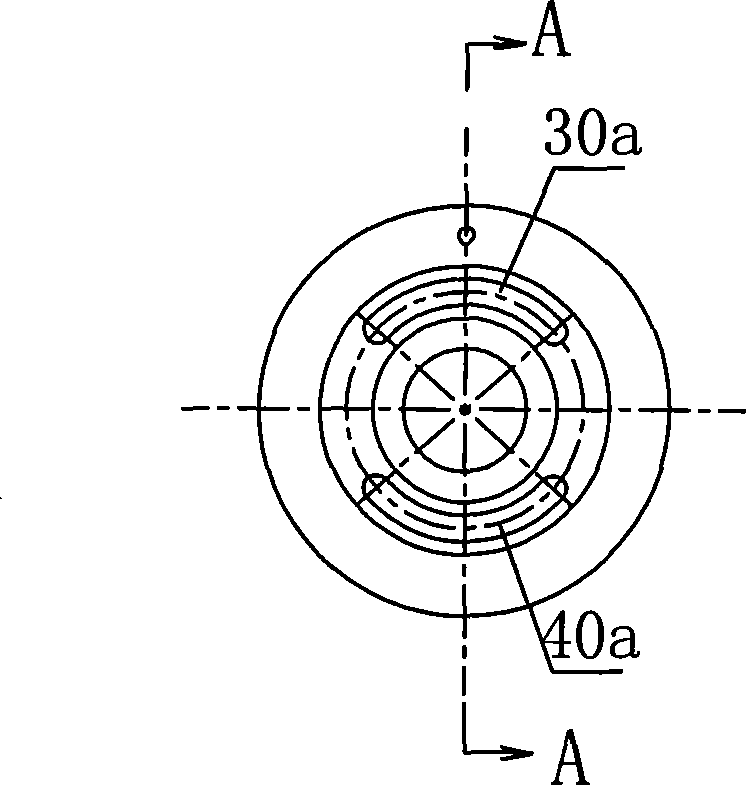

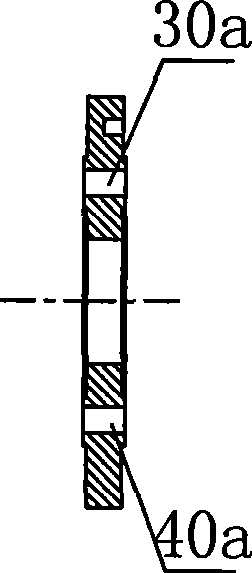

[0033] As shown in the figure, the present invention includes a rotating assembly, and the rotating assembly includes: a drive shaft 1, a rotor 17, a left thrust plate 18 and a right thrust plate 15 located on both sides of the rotor 17, a spring 8, and a spring 8. The pressing rod 9 of the right thrust plate 15 is squeezed to the right, and the right end of the pressing rod is arranged coaxially with the drive shaft and pressed against the right thrust plate 15. The spring is between the pressing rod and the drive shaft. The left thrust plate 18 and the right thrust plate 15 are slidable in the axial direction of the drive shaft and the distance between them is greater than the length of the rotor; several shafts with the drive shaft are evenly arranged in the rotor 17 along the circumference of the rotor To the parallel holes, the distribution pipes 7 are respectively arranged in the holes. In this embodiment, a total of 5 holes are provided, and accordingly, a total of 5 dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com