Multiple-in-one LED display screen module surface paste and display screen module

An LED display and LED chip technology, applied in lighting and heating equipment, instruments, identification devices, etc., can solve the problems of poor color consistency, high antistatic requirements, and troublesome processing technology, and achieve low production costs and color consistency. Good, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

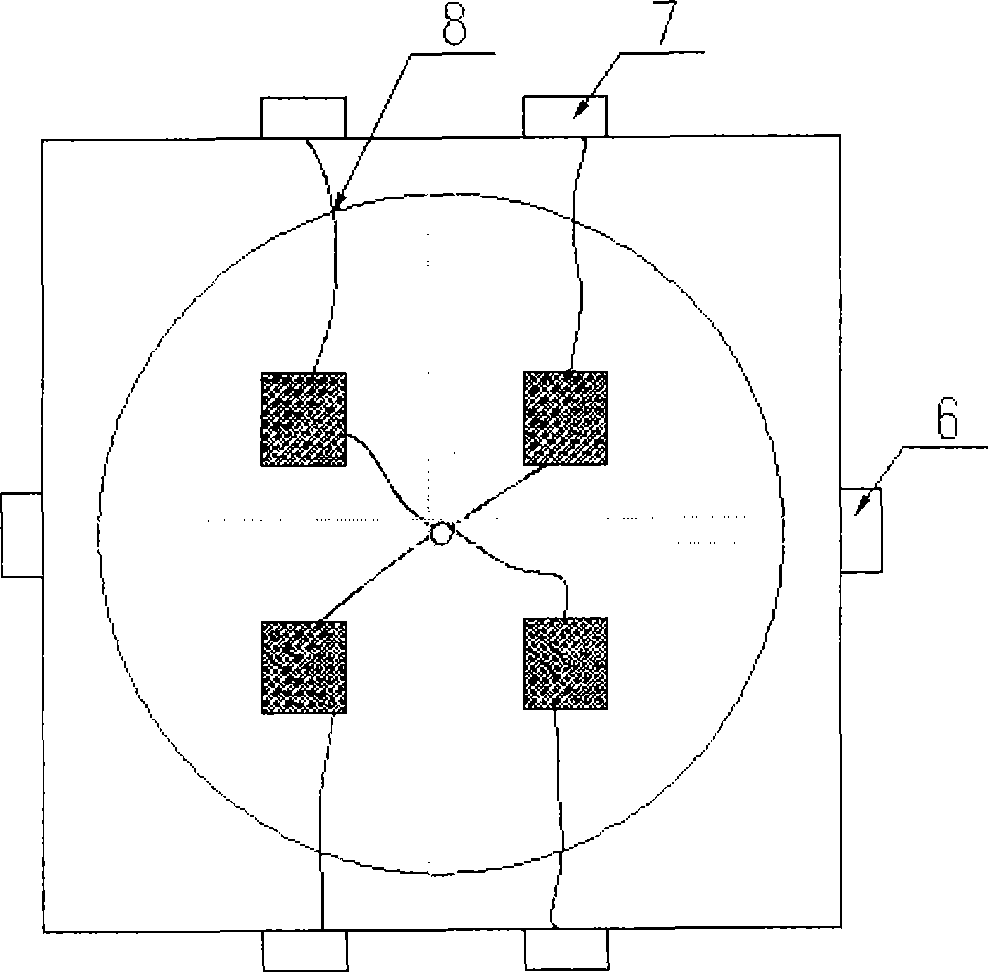

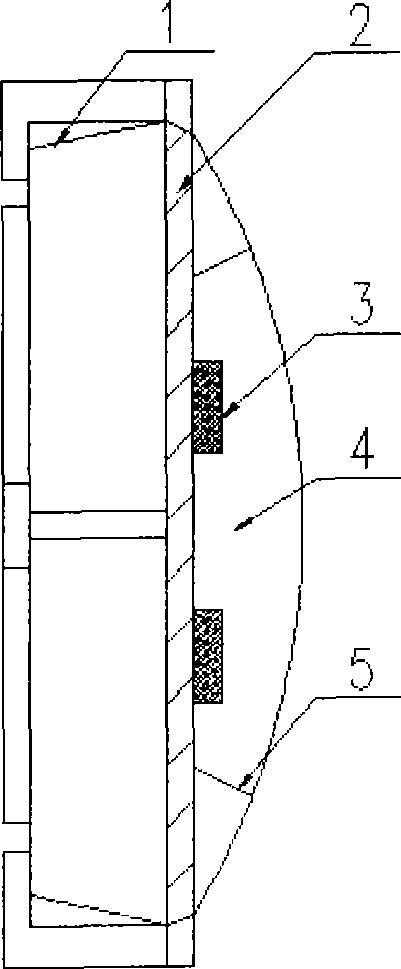

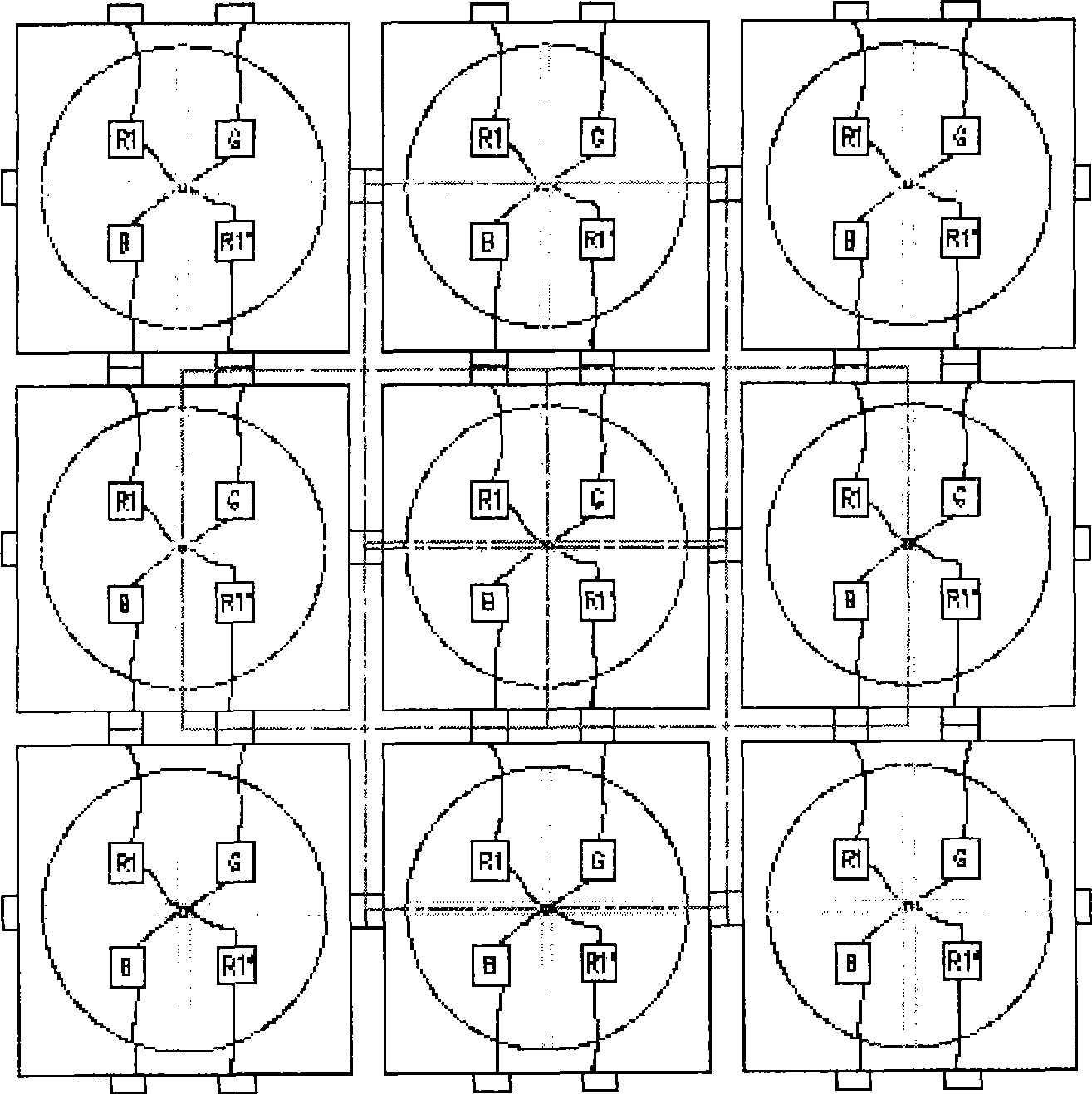

[0033] Such as figure 1 , figure 2 As shown, an all-in-one LED display module surface mount of the present invention, the carrier of the module is a hollow and transparent ceramic prefabricated part base 1 in the shape of a quadrangular truss, and the prefabricated part base is a printed circuit board 2 with 2-4 layers , the upper surface layer of the printed circuit board 2 is provided with two-dimensional grid points, each grid point is provided with a pad, and LED chips 3 are mounted or welded in the grid points, and each grid point is arranged at equal intervals, and the distance range is 2.54 ~7.62mm. The hollow part of the reflective bowl 5 arranged on the printed circuit board 2 is injected with a protective glue 4, and the protective glue is silica gel or epoxy resin glue with diffusing agent or UV glue. During the curing process, the rubber surface is secondary-molded with a specific processing mold to form a light-emitting surface.

[0034] In addition, the print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com