Intelligent control system of water pressure test in cavity

An intelligent control system and hydraulic testing technology, applied in the direction of electrical testing/monitoring, etc., can solve the problems of low pressurization control precision, low degree of automation, and inaccurate test data, so as to improve control accuracy and work safety, Realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

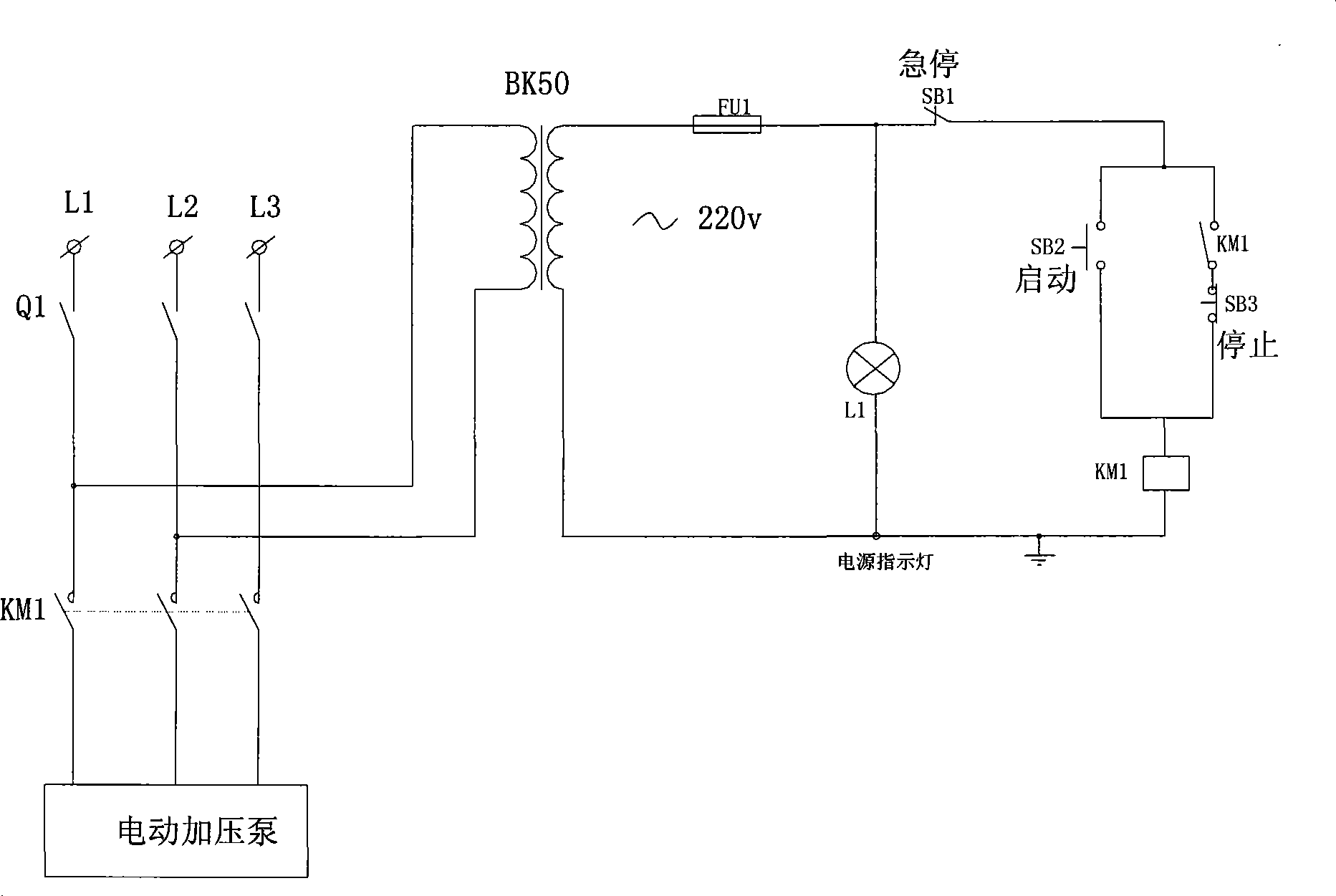

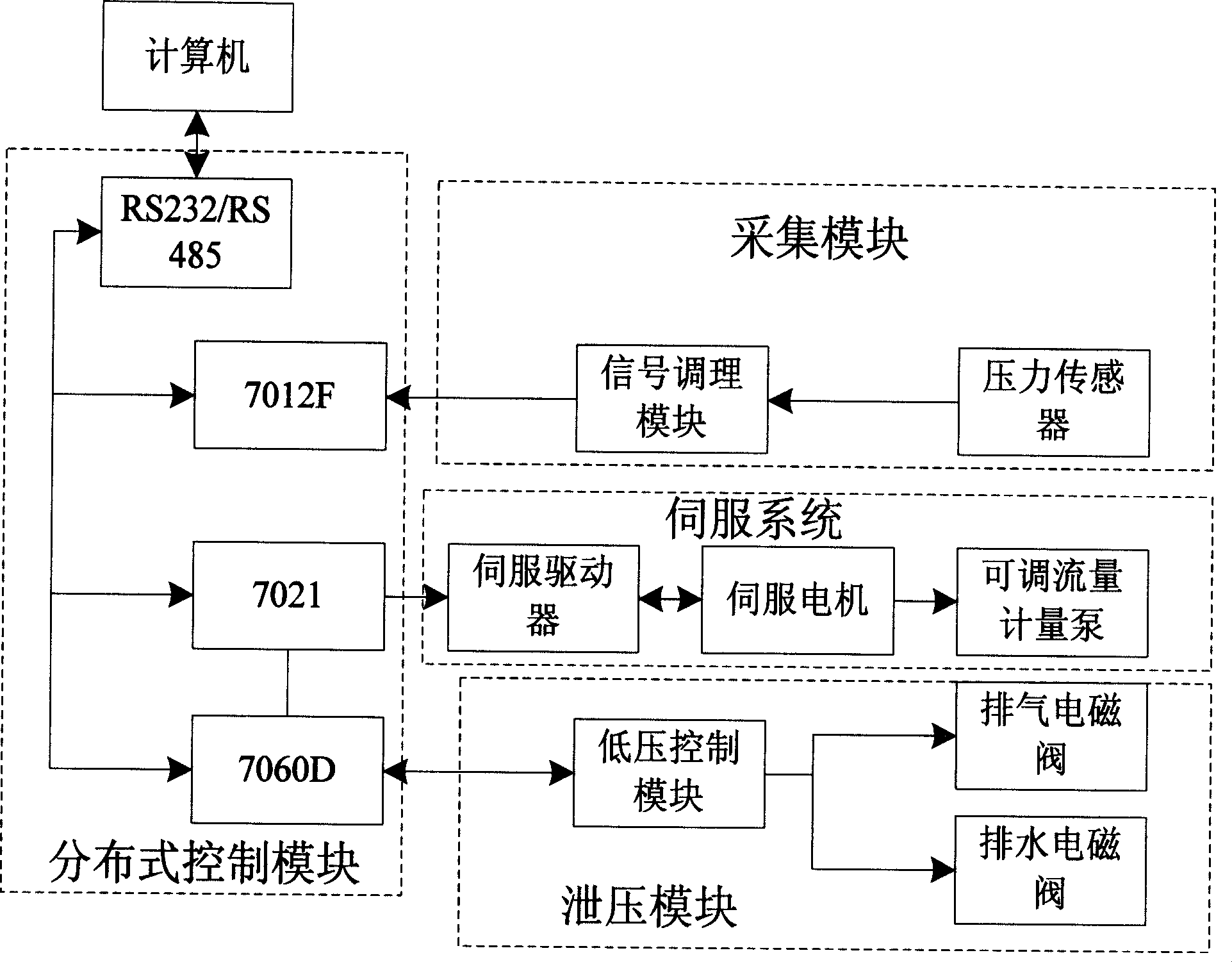

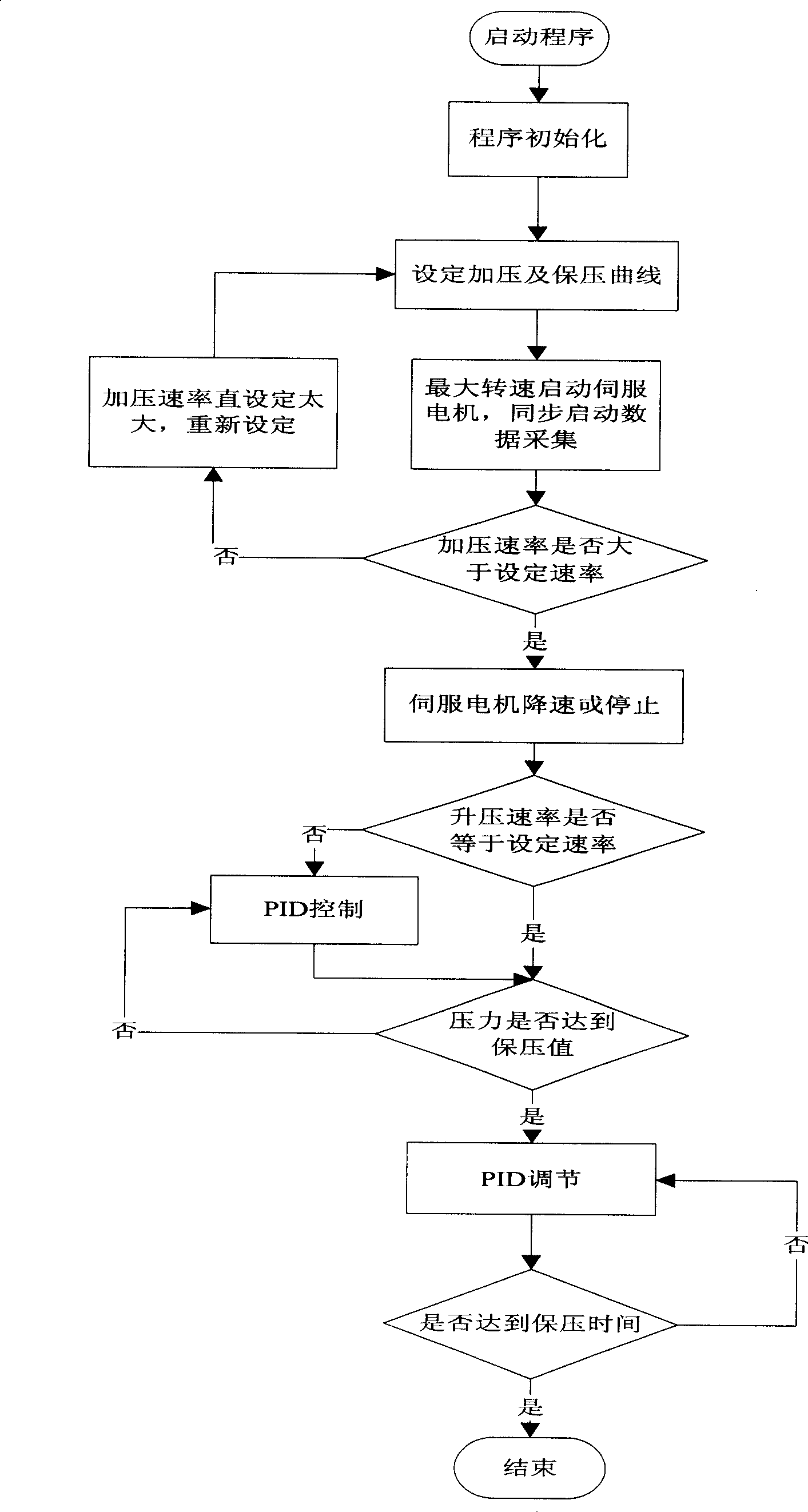

[0019] like figure 2 , 3 , 4, the present invention is mainly composed of a distributed control module, a data acquisition module, a pressure relief control module and a servo system. The distributed control module is composed of 7012F analog input module, 7021 analog output module, 7060D switch module, RS485 measurement and control work platform and software system; the data acquisition module is composed of pressure sensor HST2011B, signal processing module AM-T-I4 / U10; the pressure relief control module is composed of low pressure control module JTX—3C and exhaust and drain solenoid valve B4023 / 1001 / .182 DN15 2 / 529-37-0615-.242; the servo system is composed of servo driver HSV- 16-050, servo motor GK6063-6, adjustable flow plunger metering pump JZ—2 7 / 50.

[0020] The 7012F analog input module is used to collect the chamber water pressure data mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com