Solar high power condense photovoltaic electrification die set

A high-power concentrating and photovoltaic power generation technology, applied in photovoltaic power generation, photovoltaic modules, light radiation generators, etc., can solve the problems of large-scale production and assembly of unfavorable products, complex manufacturing process, and high production costs, so as to reduce power generation costs, Effect of increasing power generation efficiency and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

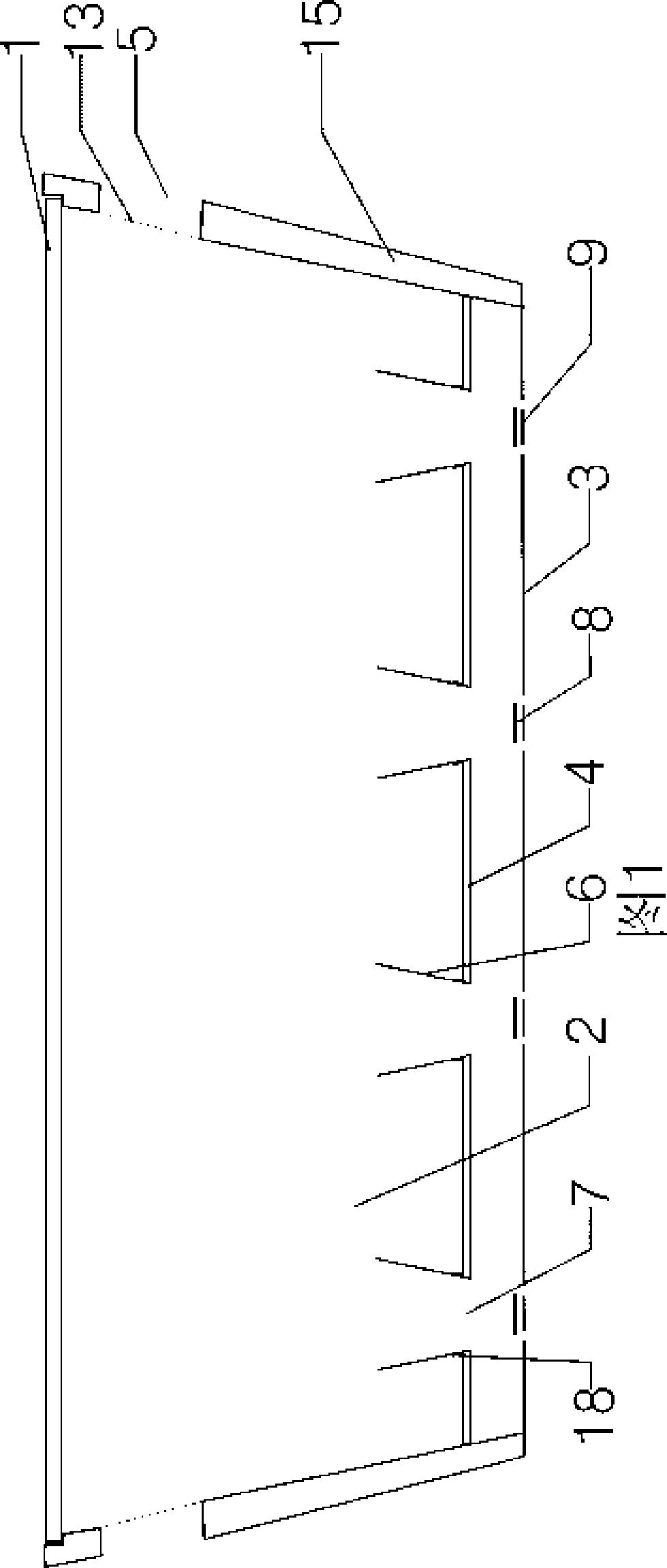

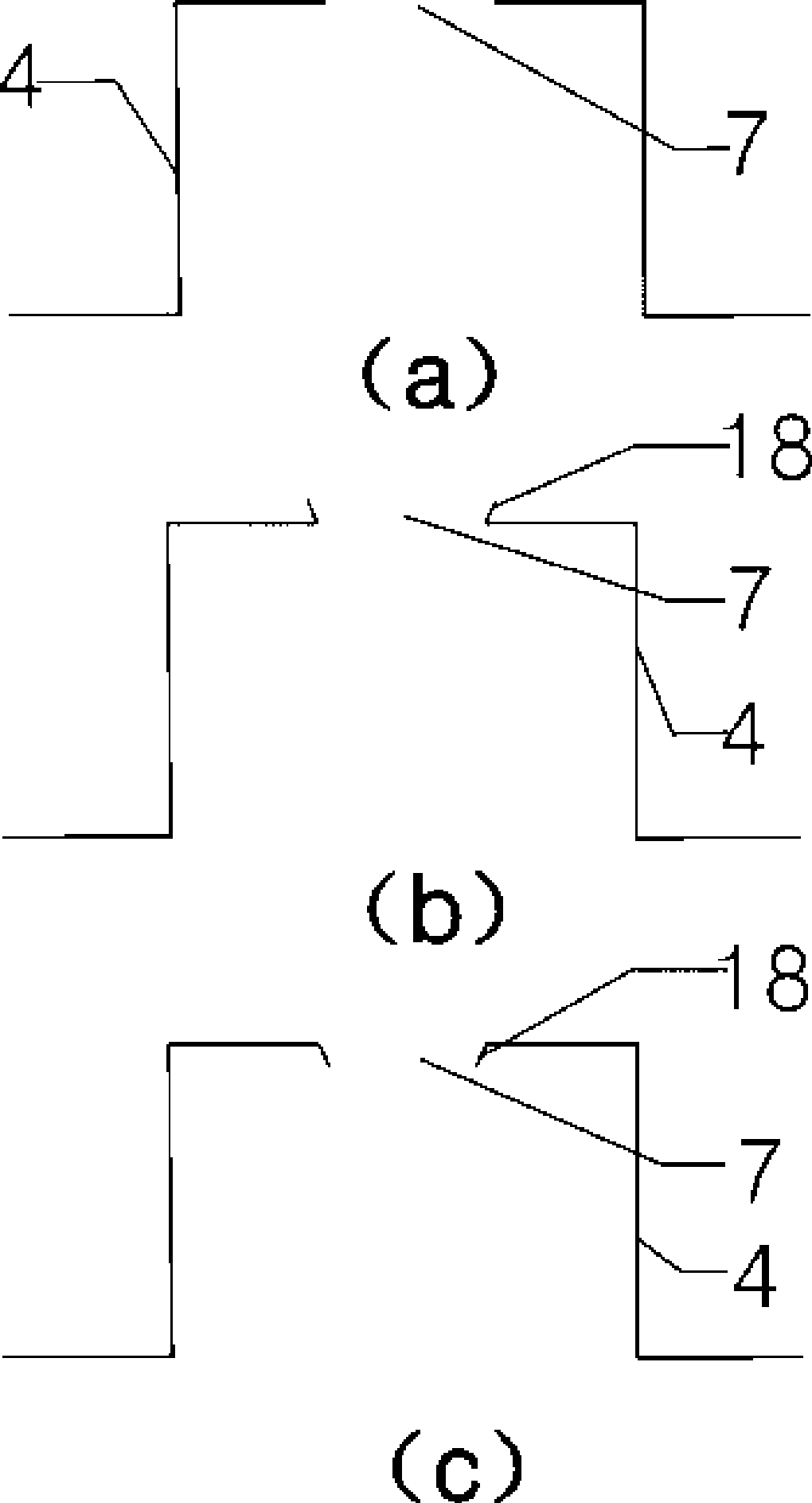

[0041]As shown in Figures 1, 3, 4, 5, 10 and 11, the solar energy high concentration photovoltaic power generation module of the present invention includes a Fresnel lens 1, a receiver, an anti-focus plate 4, a light guide funnel 6 and a module The box body 2, the Fresnel lens 1 is a one-time molded Fresnel lens array or a one-time molded Fresnel lens array made of tempered glass as a substrate, and the Fresnel lens array includes two Block or more than two Fresnel lens monomers 14, each Fresnel lens monomer 14 upper surface is on the same level, for further strengthening the anti-wind and sand ability of Fresnel lens 1, also can be in each Fresnel lens Reinforcing ribs 12 are arranged equidistantly between the monomers 14 and molded at one time to enhance the surface hardness. The Fresnel lens 1 is installed on the upper part of the module box body 2, the length of the bottom plate 3 of the module box body 2 is shorter than the length of the Fresnel lens 1 installed on the up...

Embodiment 2

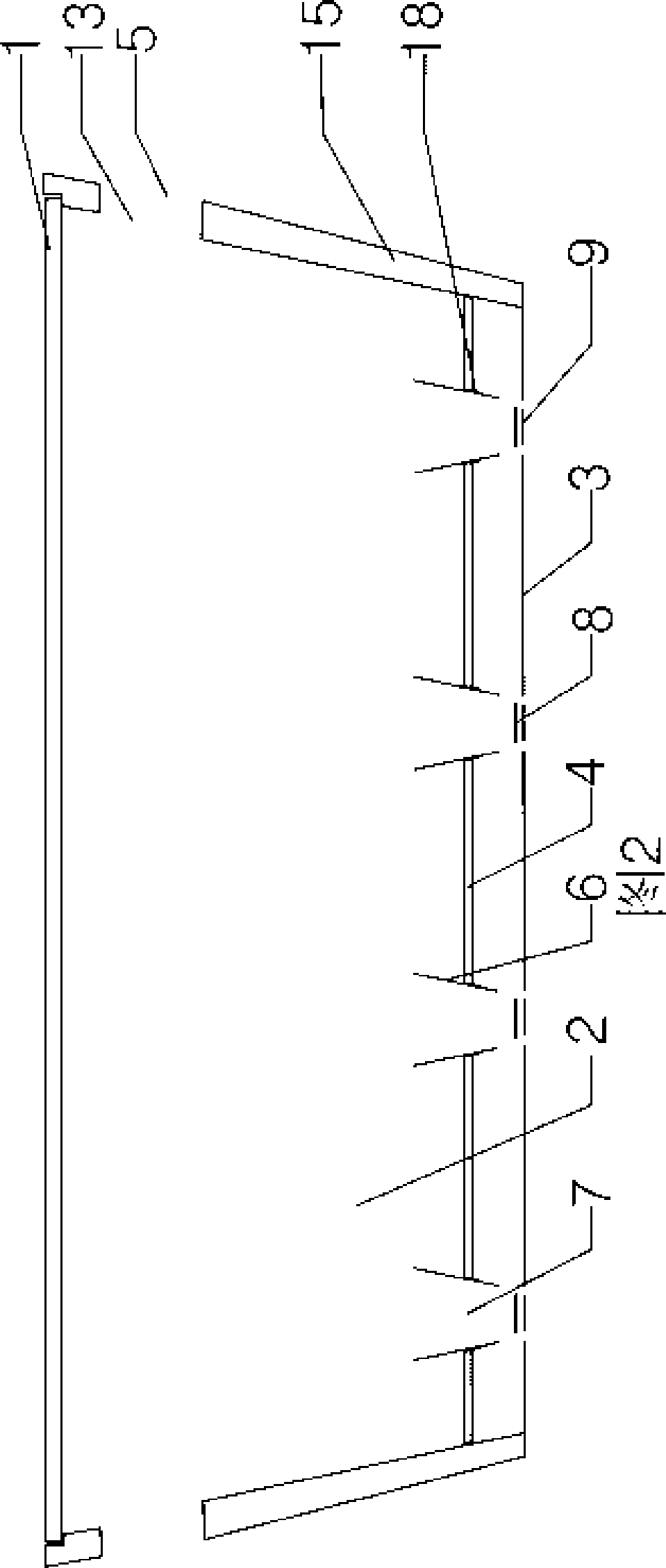

[0043] As shown in Figures 2, 3, 4, 5, 10 and 11, the solar energy high concentration photovoltaic power generation module of the present invention includes a Fresnel lens 1, a receiver, an anti-focus plate 4, a light guide funnel 6 and a module The box body 2, the Fresnel lens 1 is a one-time molded Fresnel lens array or a one-time molded Fresnel lens array made of tempered glass as a substrate, and the Fresnel lens array includes two Block or more than two Fresnel lens monomers 14, each Fresnel lens monomer 14 upper surface is on the same level, for further strengthening the anti-wind and sand ability of Fresnel lens 1, also can be in each Fresnel lens Reinforcing ribs 12 are arranged equidistantly between the monomers 14 and molded at one time to enhance the surface hardness. The Fresnel lens 1 is installed on the upper part of the module box body 2, the length of the bottom plate 3 of the module box body 2 is shorter than the length of the Fresnel lens 1 installed on the u...

Embodiment 3

[0045] As shown in Figures 6, 10 and 11, the solar energy high concentration photovoltaic power generation module of the present invention includes a Fresnel lens 1, a receiver, an anti-focus plate 4, a light guide funnel 6 and a module box body 2, Fresnel The Fresnel lens 1 is a Fresnel lens array formed by one-time compression molding or a Fresnel lens array formed by one-time compression molding and bonding of tempered glass as a substrate. The Fresnel lens array includes two or more than two Fresnel lens monomer 14, each Fresnel lens monomer 14 upper surfaces are on the same level, for further strengthening the wind and sand resistance of Fresnel lens 1, also can wait between each Fresnel lens monomer 14 The distance is provided with reinforcing ribs and molded at one time to enhance its surface hardness. The Fresnel lens 1 is installed on the upper part of the module box body 2, the length of the bottom plate 3 of the module box body 2 is shorter than the length of the Fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com