Compositions and methods for fluid purification

A fluid, iodinated technique with applications discussed in 75 and 4,995,976. It can solve the problems of high cost and pollution of storage facilities, and achieve the effect of increased volume and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

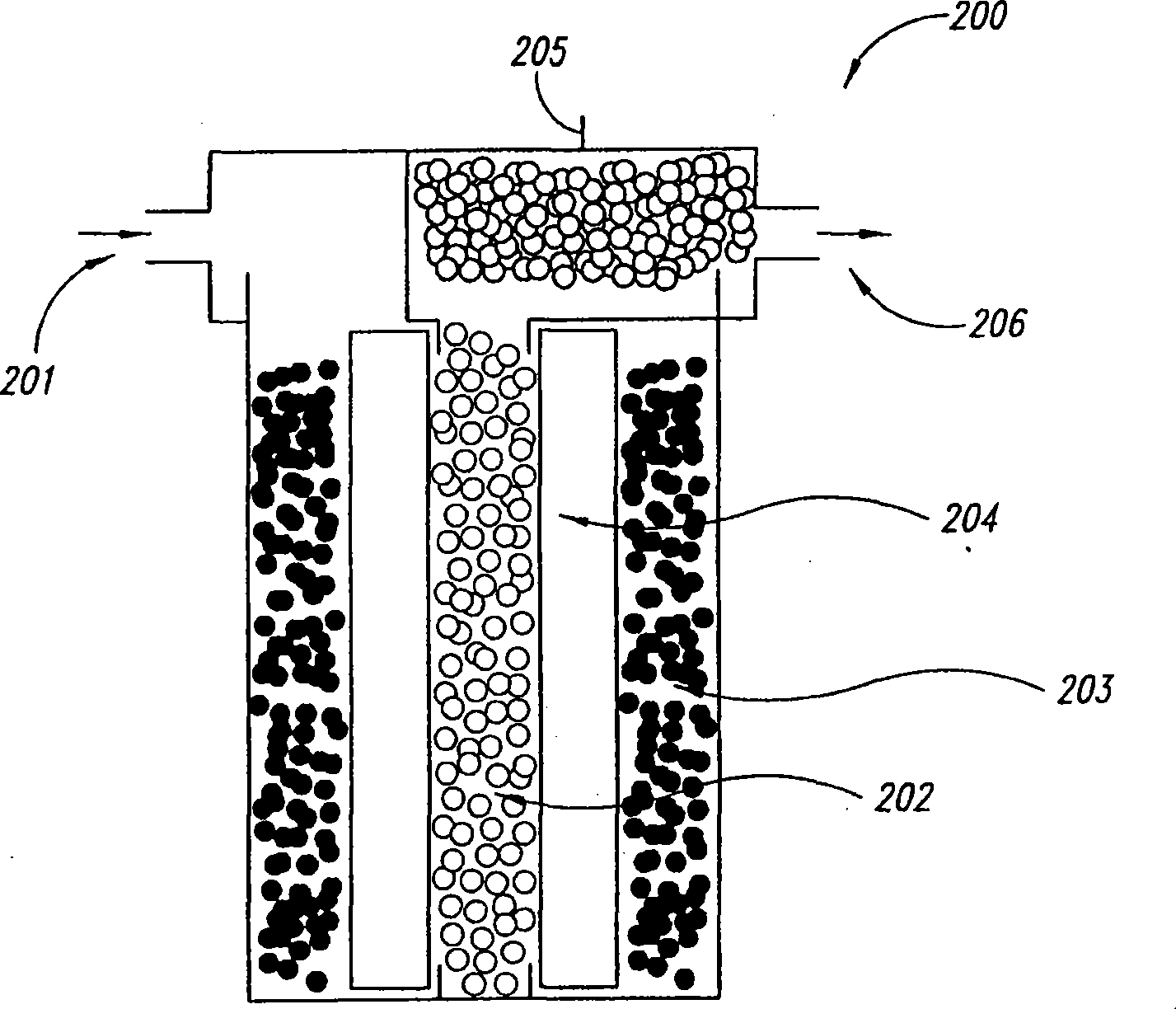

[0093] The ability of a fluid filtration system 600, which represents an embodiment of the present invention, to remove contaminants from an unpurified fluid was tested (see Image 6 ). Specifically, raw water is introduced into the inflow opening 601 of the system and communicated with Iodinated resin column 602 (approximately 5.5 mL) contacts, then flows through Nano-alumina fiber material 604 and dispensed through effluent opening 605. at position 603 with post-contact and at position 605 with the The material is tested for contamination after exposure. The flow through the system was 20 mL / min upstream. The test results are shown in Tables 1 and 2, where no detectable spread of MS2 or E. coli contamination occurred. SP1 represents the test at position 603 and SP2 represents the test at position 605 .

[0094] Table 1

[0095] MCV+Argonide: Escherichia coli 20mL / min @pH~8.0; t=21°-25℃

[0096]

[0097] Table 2

[0098] MCV+Argonide: MS220mL / min @pH...

Embodiment 2

[0101] In an independent test using a separate Argonide filter, transmission of both MS2 and E. coli occurred after approximately 2.75 liters of water passed through a single filter unit. The results of individual Argonide filter tests are shown in Tables 3 and 4.

[0102] table 3

[0103] Separate Argonide filter: E. coli 10mL / min; pH ~ 8.0; t=21°-25℃

[0104] sample result

(cfu / 100mL) log 10

Inactivate inflow 3.00E+06 Escherichia coli 4.6h (2.76L) 48 4.80

[0105] Table 4

[0106] Separate Argonide filter: MS210mL / min; pH~8.0; t=21°-25℃

[0107] sample result

Embodiment 3

[0109] Utilize something like Image 6 The manifold shown in the test was performed. However, 5.5 mL of "typical" MCV was replaced with 20 mL of LR-1 iodinated resin.

[0110] Table 5 summarizes the microbial inactivation data as a function of the barrier used (LR-1 → low residue iodinated resin; Argonide; LR-1+Membrane → a tandem combination of two barriers).

[0111] table 5

[0112] Inactivation of Klebsiella terrigena (pH7±0.1; t=20±1°C)

[0113]

[0114] Influent (cfu / L): 1.40×10 8 -1.51×10 8

[0115] Table 6 compares the MS2 inactivation obtained with the LR-1 / membrane combination and with the membrane alone and LR-1 alone as a function of challenge solution flow.

[0116] Table 6

[0117] MS2 inactivation (pH7±0.1; t=20±1°C)

[0118]

[0119] Influent (pfu / L): 8.95×10 7 -1.17×10 8

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com