Electrophotographic photosensitive body, image forming device, and electrophotographic cartridge

A technology of electrophotography and photoreceptor, which is applied in the fields of optics, electrical recording, instruments, etc. It can solve the problem of high doping amount of photoconductive substances and achieve high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0882] [Coating solution for undercoat layer]

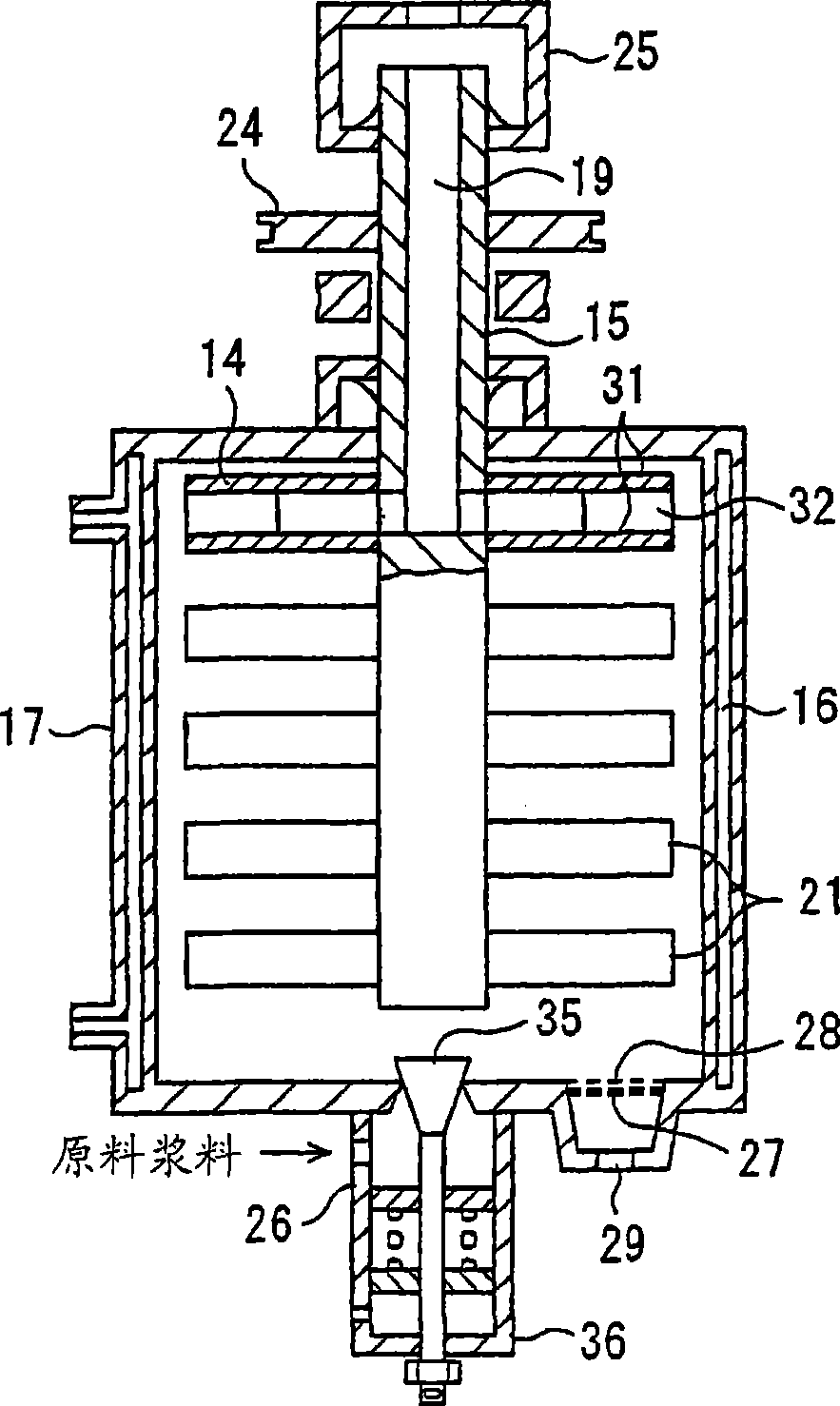

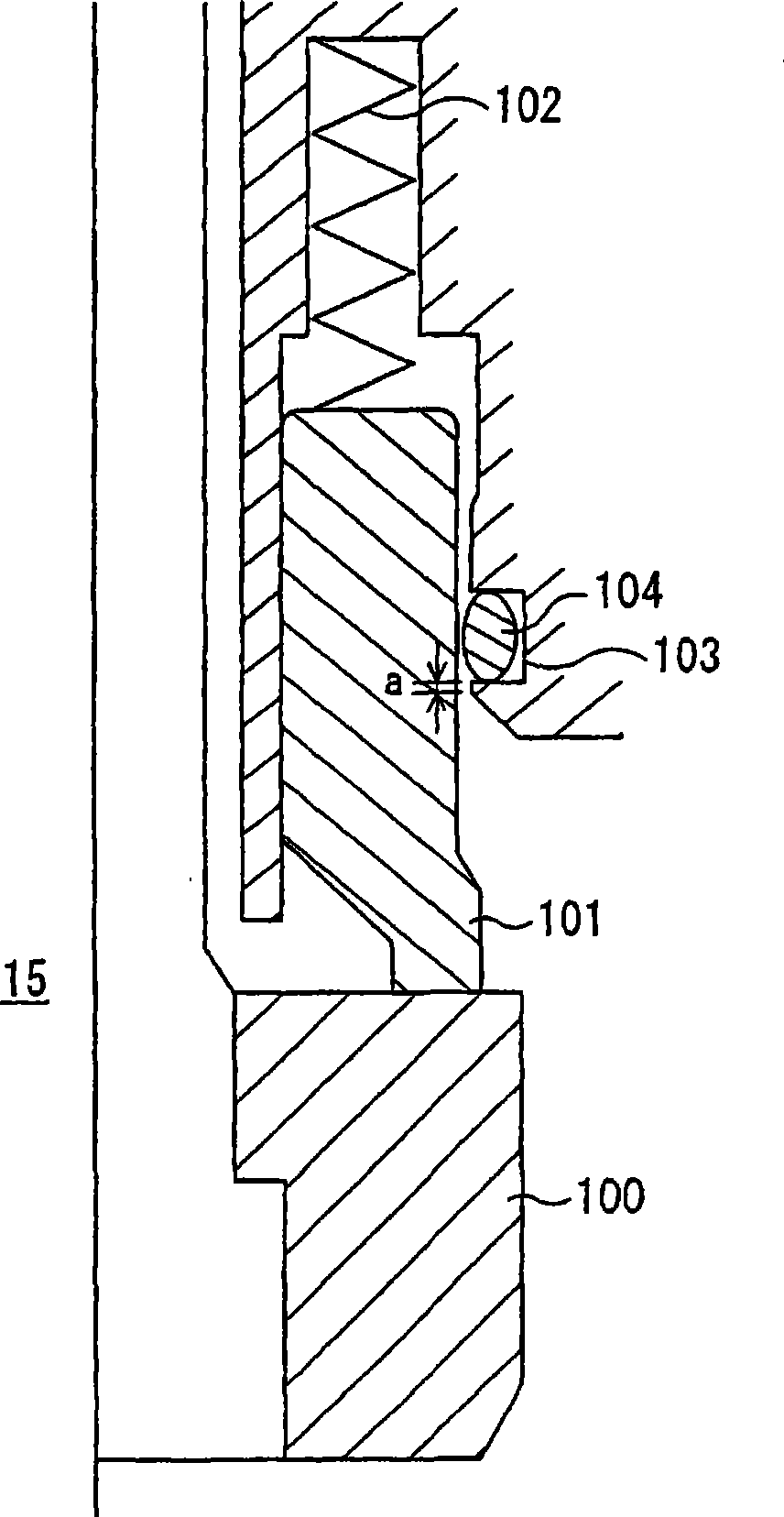

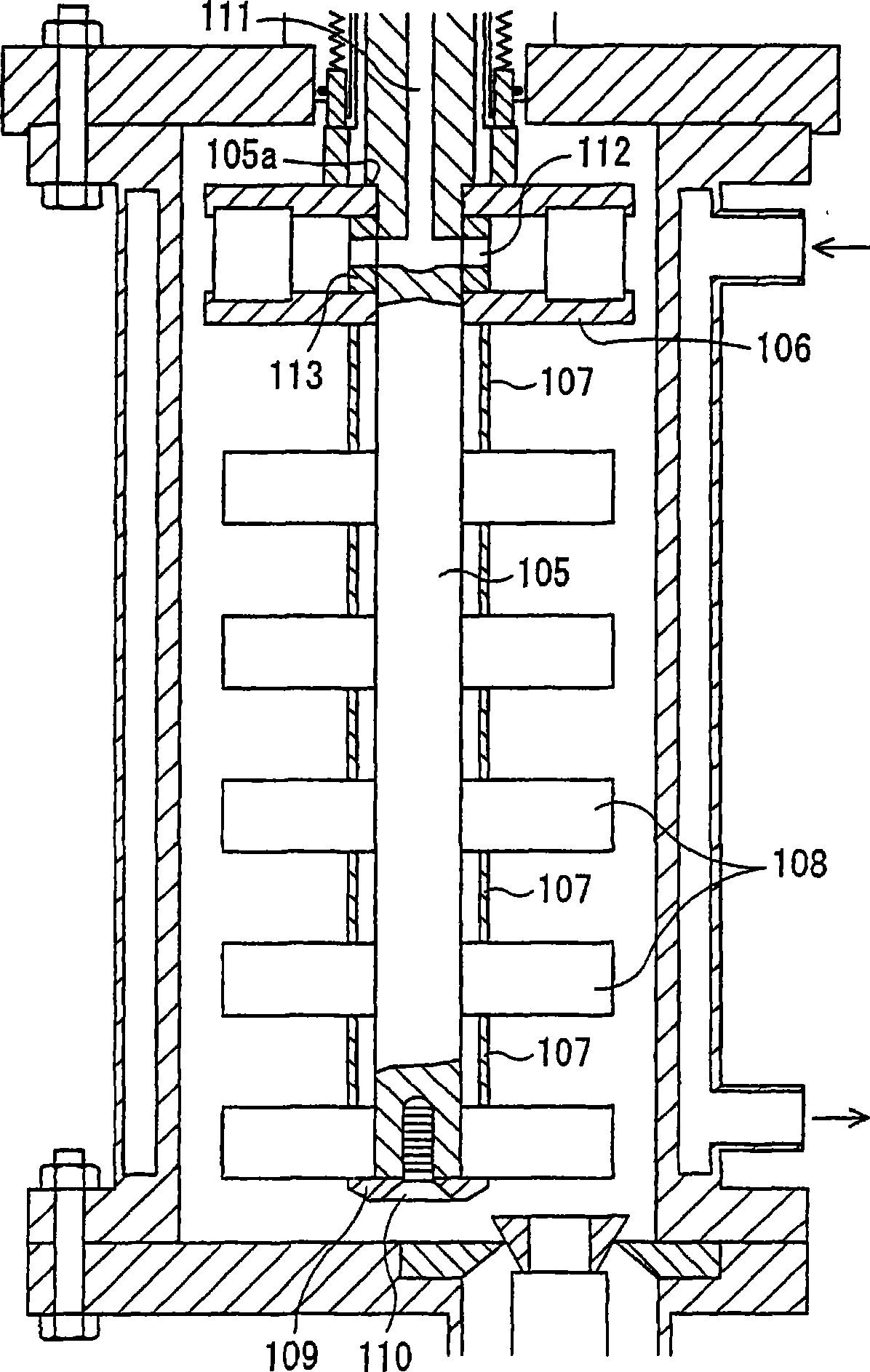

[0883] Rutile titanium dioxide (manufactured by Ishihara Sangyo Co., Ltd., "TTO55N") with an average primary particle diameter of 40 nm and methyldimethoxysilane (manufactured by Toshiba Silicone Co., Ltd. " TSL8117") were mixed to obtain surface-treated titanium dioxide, 50 parts of the surface-treated titanium dioxide and 120 parts of methanol were mixed to form a raw material slurry, and zirconia beads (manufactured by NIKKATO CORPORATION, YTZ) with a diameter of about 100 μm were used as the dispersion medium, using a grinder The ULTRA APEXMILL (UAM-015 type) manufactured by Kotobuki Industrial Co., Ltd. with a volume of about 0.15L was used to disperse 1 kg of the raw material slurry for 1 hour in a liquid circulation state with a rotor peripheral speed of 10 m / s and a liquid flow rate of 10 kg / hour. A titanium dioxide dispersion was produced.

[0884]Under heating, the mixed solvent of the above-mentioned titanium dioxide ...

Embodiment 1-2

[0901] As the binder resin, the following compound was used instead of compound (P-1) (compound (P-2): viscosity average molecular weight about 40,000; polymerized according to the method described in Example 3 of Japanese Patent Application No. 2002-3828) , except that, it carried out similarly to Example 1-1, and obtained the photoreceptor 1-E2.

[0902]

Embodiment 1-3

[0904] As the binder resin, instead of compound (P-1), use the following compound (compound (P-3): viscosity-average molecular weight about 30,000; m:n=3:7; in accordance with Japanese Patent Application No. 2002-3828 (polymerization by the method described in Example 4), it carried out similarly to Example 1-1, and obtained the photoreceptor 1-E3.

[0905]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com