Optical device for generating high current density picture composition electrified particle beam

A technology of charged particle beams and charged particles, applied in the field of charged particle optics, to achieve the effect of reducing beam size and uniform deposition current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

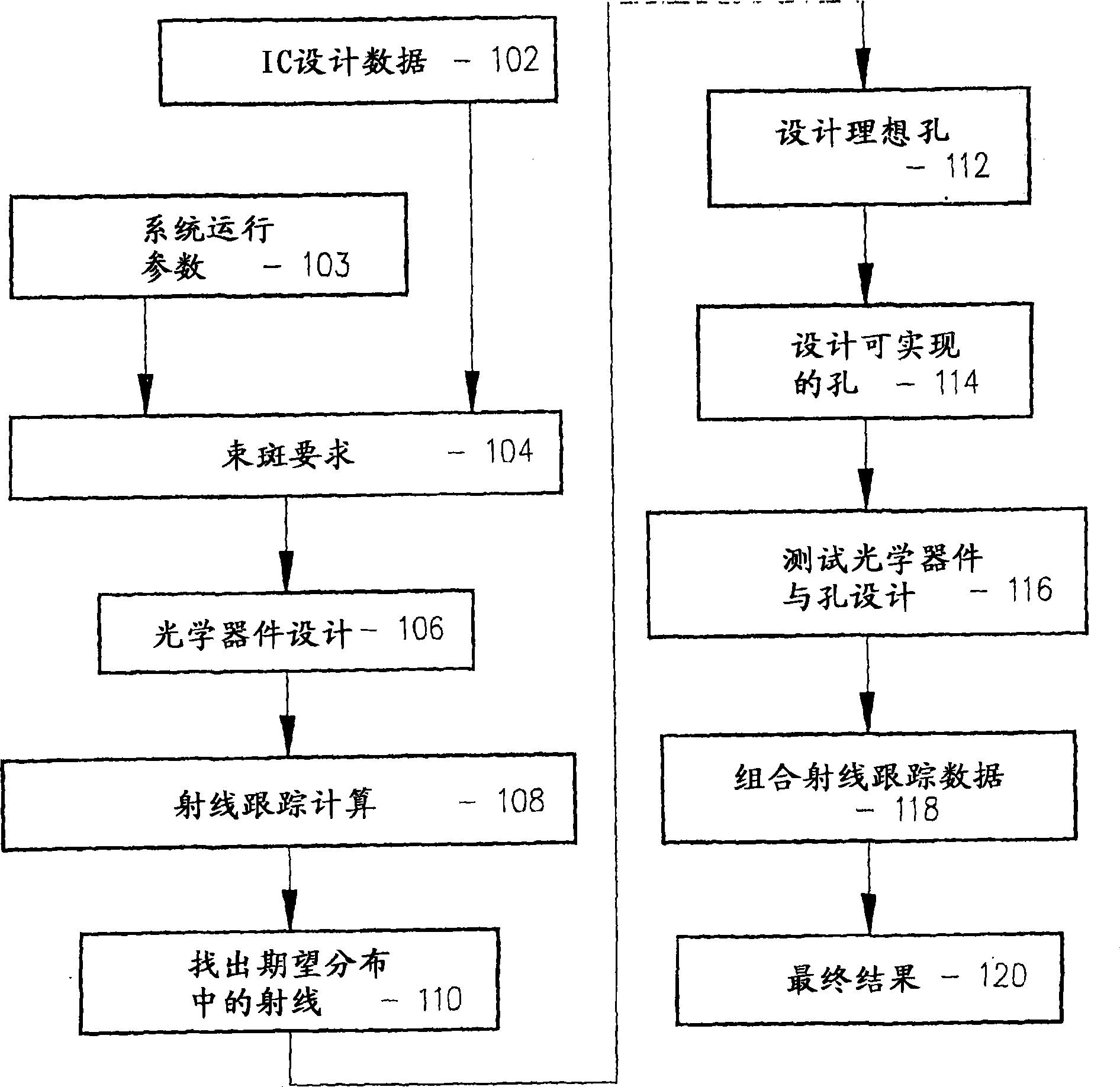

Method used

Image

Examples

Embodiment Construction

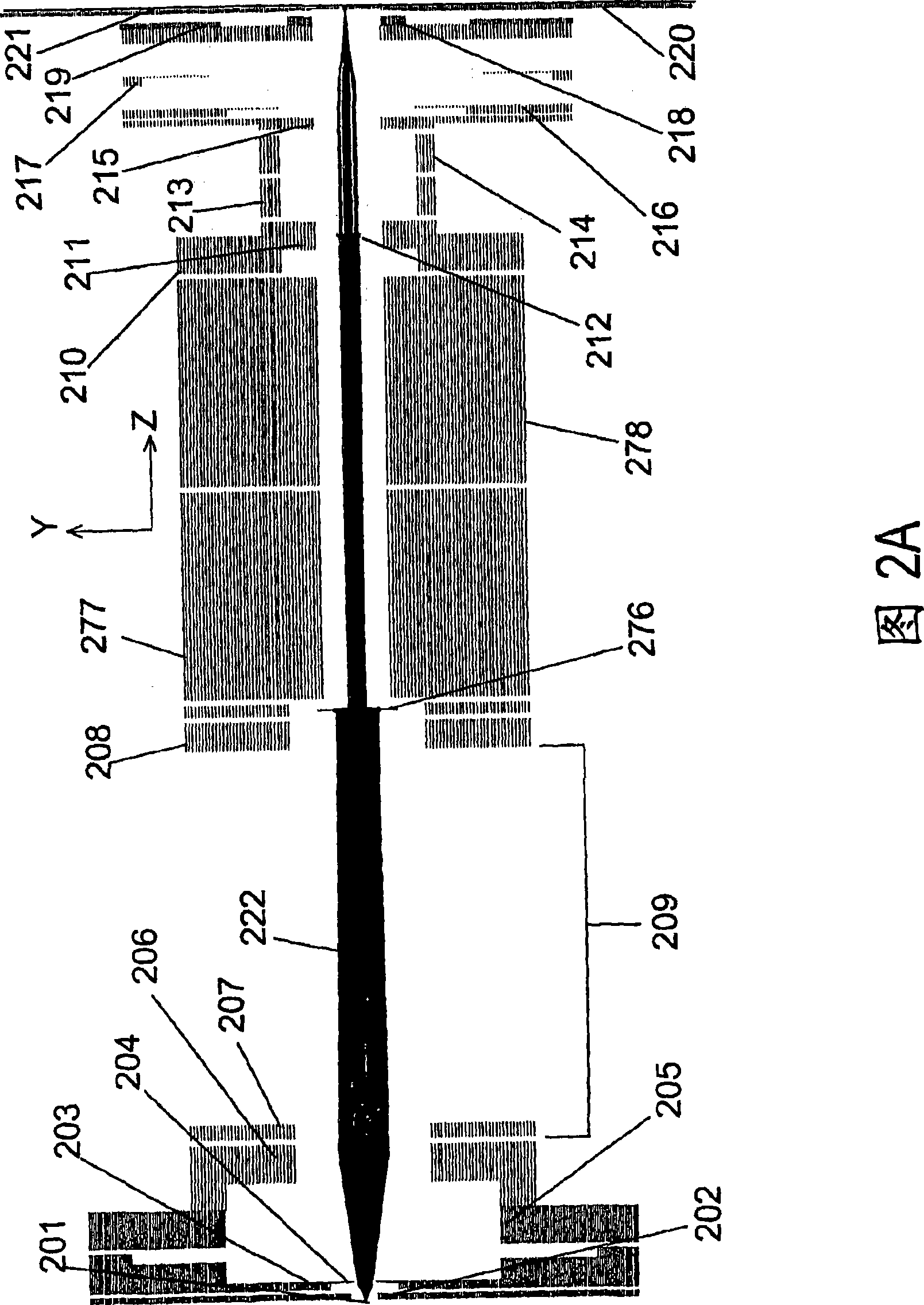

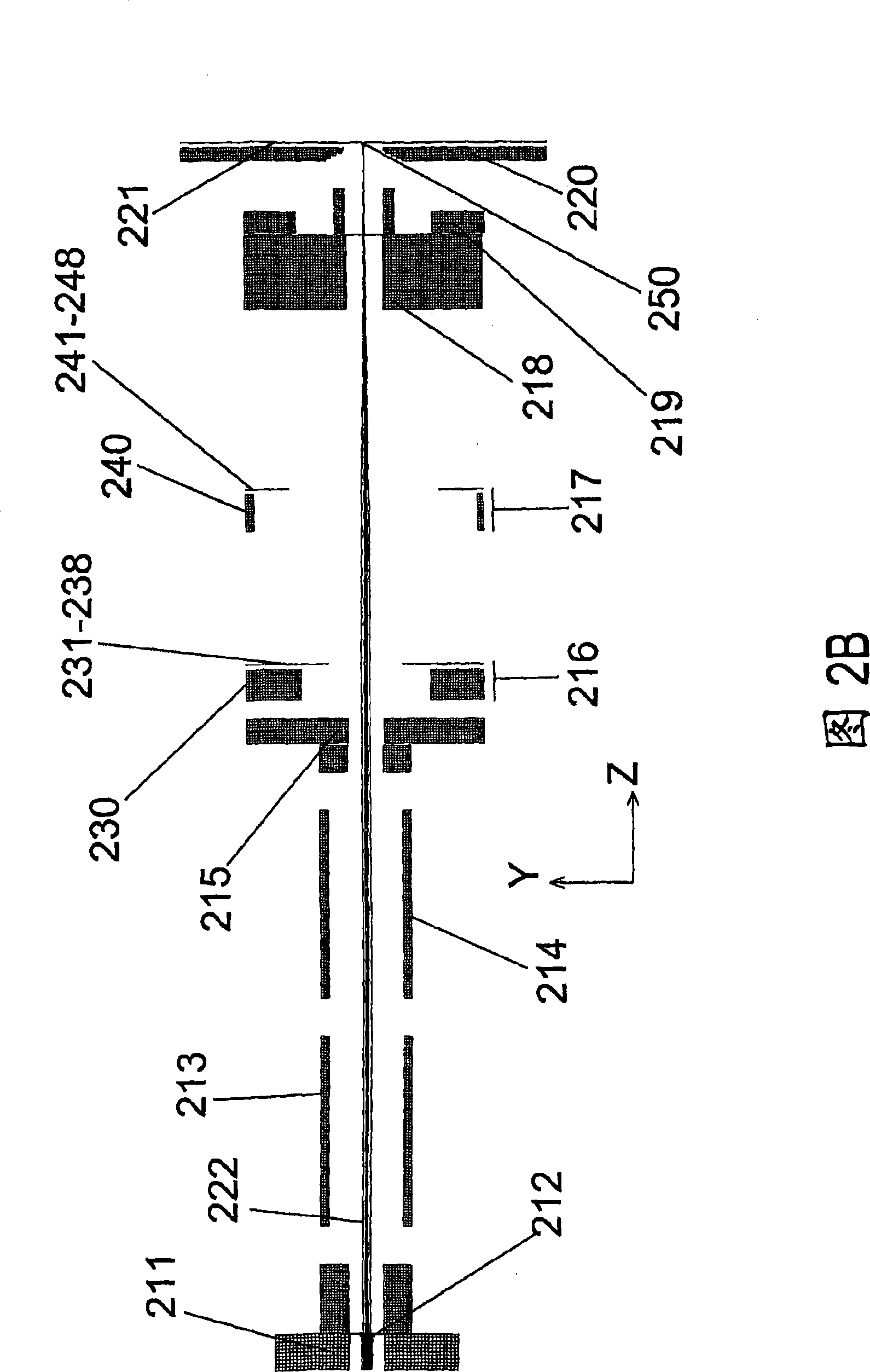

[0093] The invention will be discussed in detail with its implementation in the field of electron beam lithography as an illustrative example. However, as outlined immediately below, many other fields of application are also conceivable.

[0094] Scanning electron microscopy typically uses a roughly Gaussian beam in order to maximize beam current density, thereby minimizing imaging time and / and maximizing the signal-to-noise ratio of the image. A disadvantage of using a Gaussian beam for microscopy is the long current tail extending away from the center of the beam, which reduces the achievable image contrast. The present invention has potential use in scanning electron microscopy, reducing the extent of these current tails, thereby improving image contrast. These same considerations can be applied to many types of scanning electron beam imaging and analysis tools, such as scanning Auger microscopes, scanning electron microscopes, scanning emission electron microscopes, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com