Embedded burner of household gas cooker with multiple nozzles, high flow rate and full upward air intake

A burner and large flow technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of inability to realize independent adjustment of internal and external firepower, low thermal efficiency, and a large amount of space occupied, so as to facilitate the replacement of different gas uses , sufficient combustion and large air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

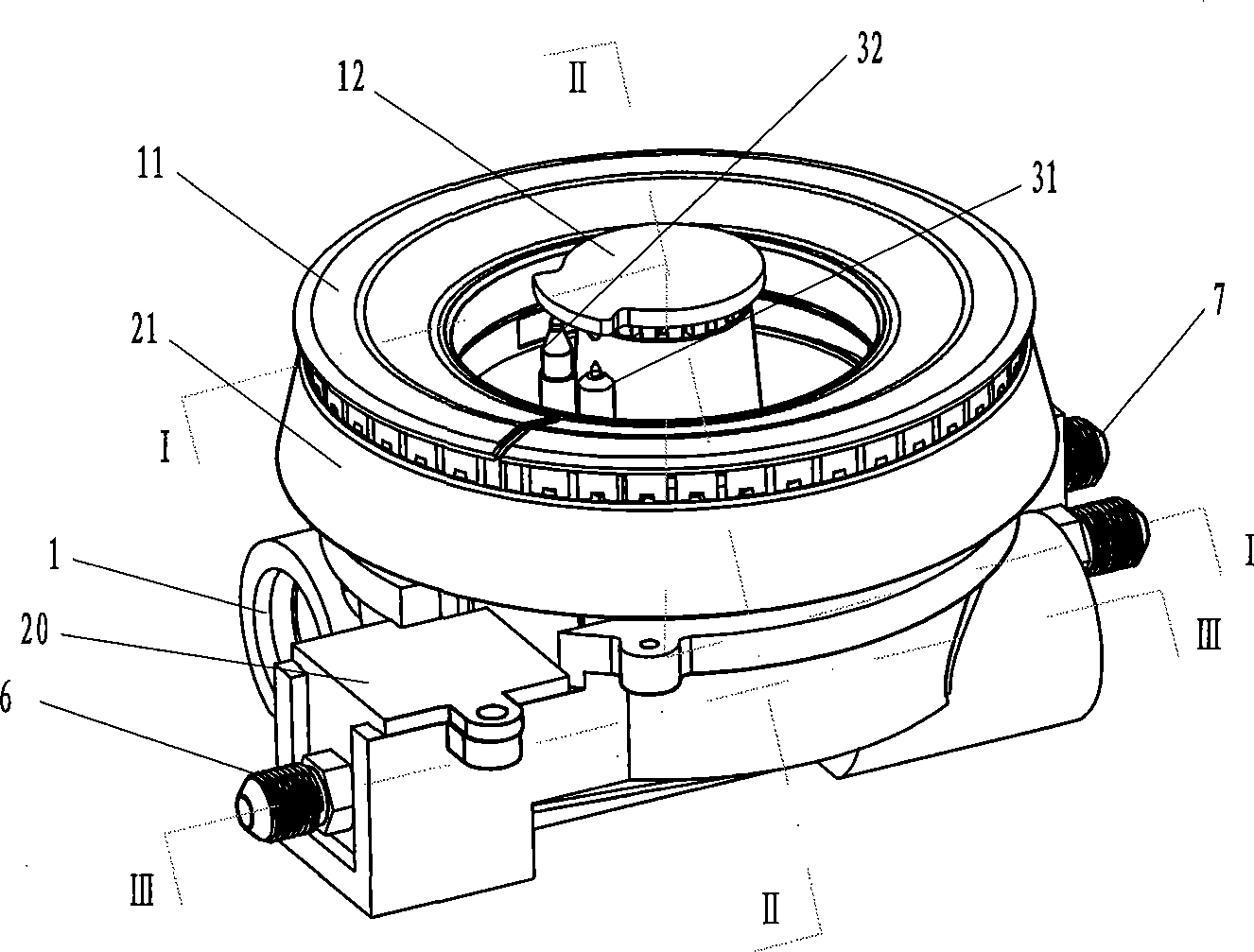

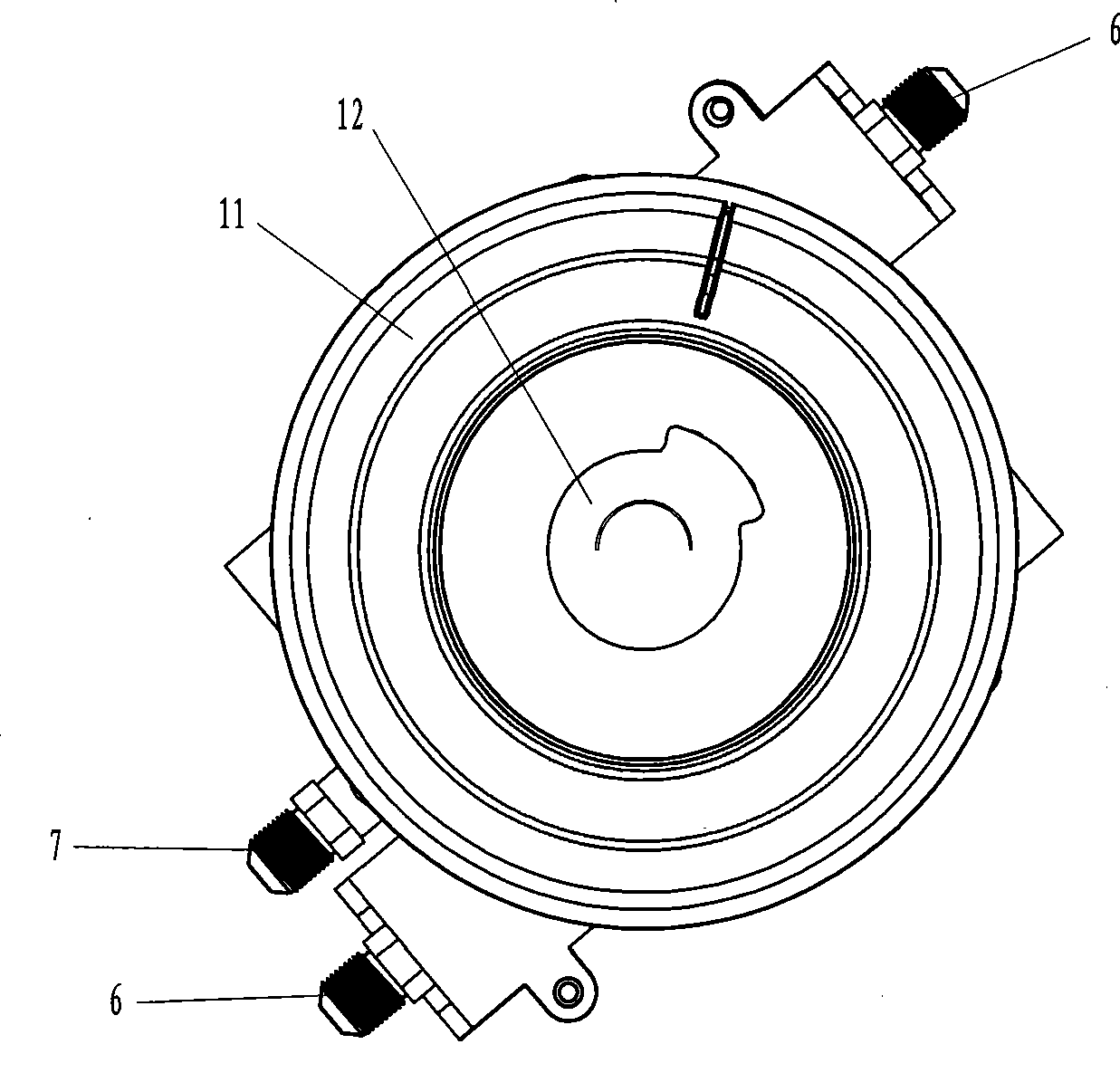

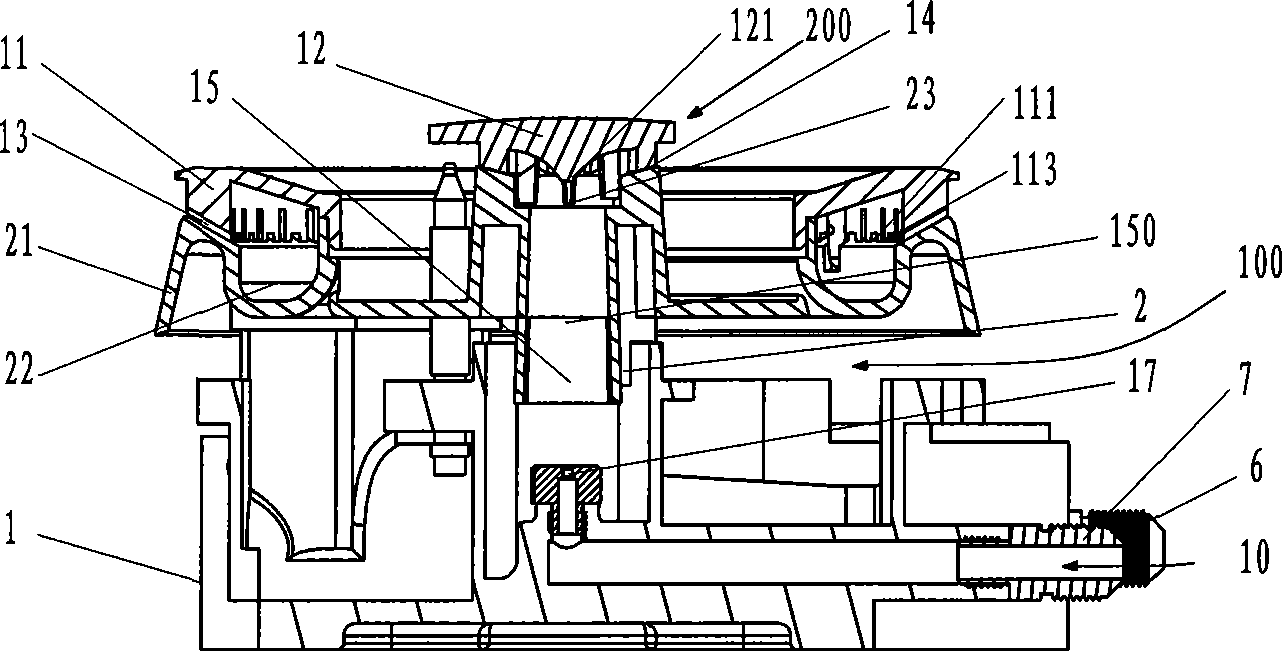

[0025] As shown in the figure, the present invention discloses a burner with multiple nozzles, large flow rate, and complete upward air intake, including a bottom cup assembly 1, inner and outer burner heads 21 placed on the bottom cup assembly, and an outer ring fire cover 11 And the inner ring fire cover 12, the bottom cup assembly 1 is provided with the outer ring gas connector 6, the inner ring gas connector 7 and the installation holes 311, 321 of the ignition needle 31 and the thermocouple 32.

[0026] from Figure 3-Figure 5 It can be seen that the outer ring fire chamber 22 is formed between the inner and outer ring burner head 2 and the outer ring fire cover 11, and the outer ring fire chamber 22 communicated with the outer ring fire chamber is arranged on the inner and outer ring burner head 2 or the outer ring fire cover 11. Hole 13, in this embodiment, as Figure 9 As shown, the bottom of the outer ring fire cover 11 is provided with several fire teeth 111 along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com