Method for producing high power varying optical attenuator

A manufacturing method and technology of attenuating sheet, applied in the direction of coupling of optical waveguides, etc., can solve the problems of rough edges of metal holes, limited selection of metal materials, complicated manufacturing processes, etc., and achieve smooth edges, low polarization-related loss, and manufacturing simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

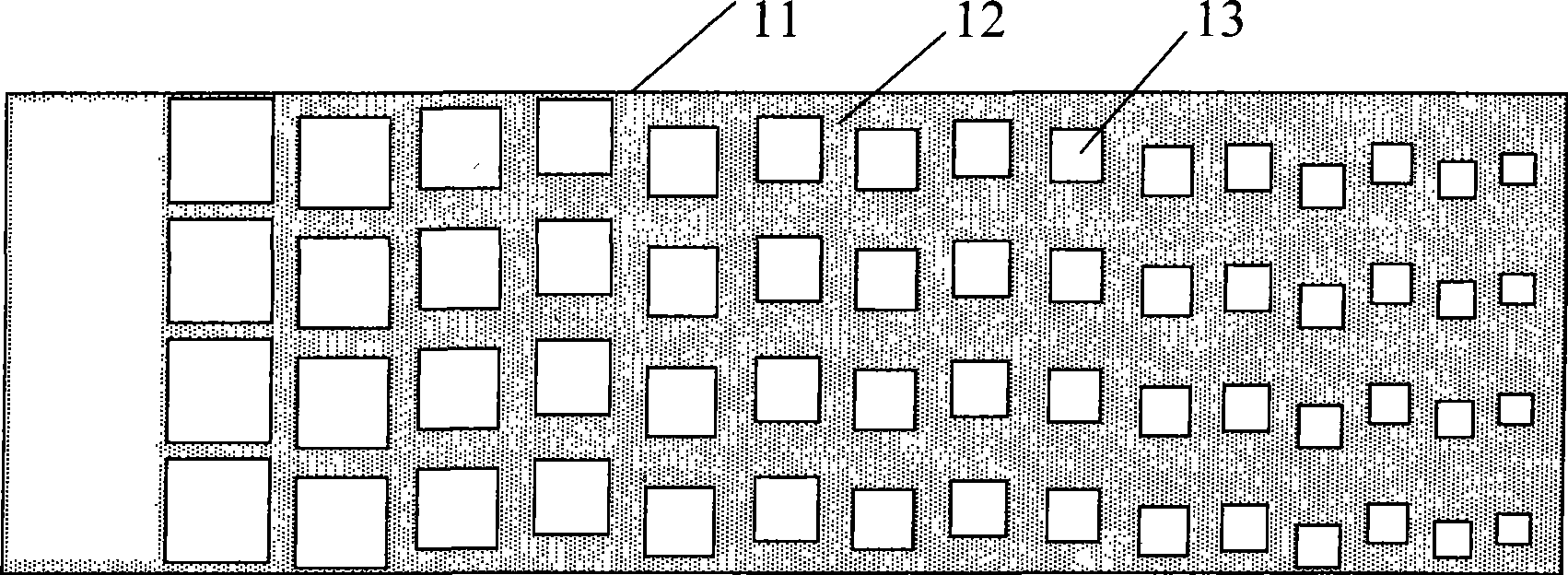

[0024] A high-power variable optical attenuation film, such as figure 1 As shown, it is composed of a thick metal film 12 plated on a glass substrate 11, and a pre-designed light-transmitting hole 13 is made on it, and the light-transmitting small holes are from left to right along the length direction of the glass substrate. The area is gradually reduced, so that the light attenuation is gradually increased.

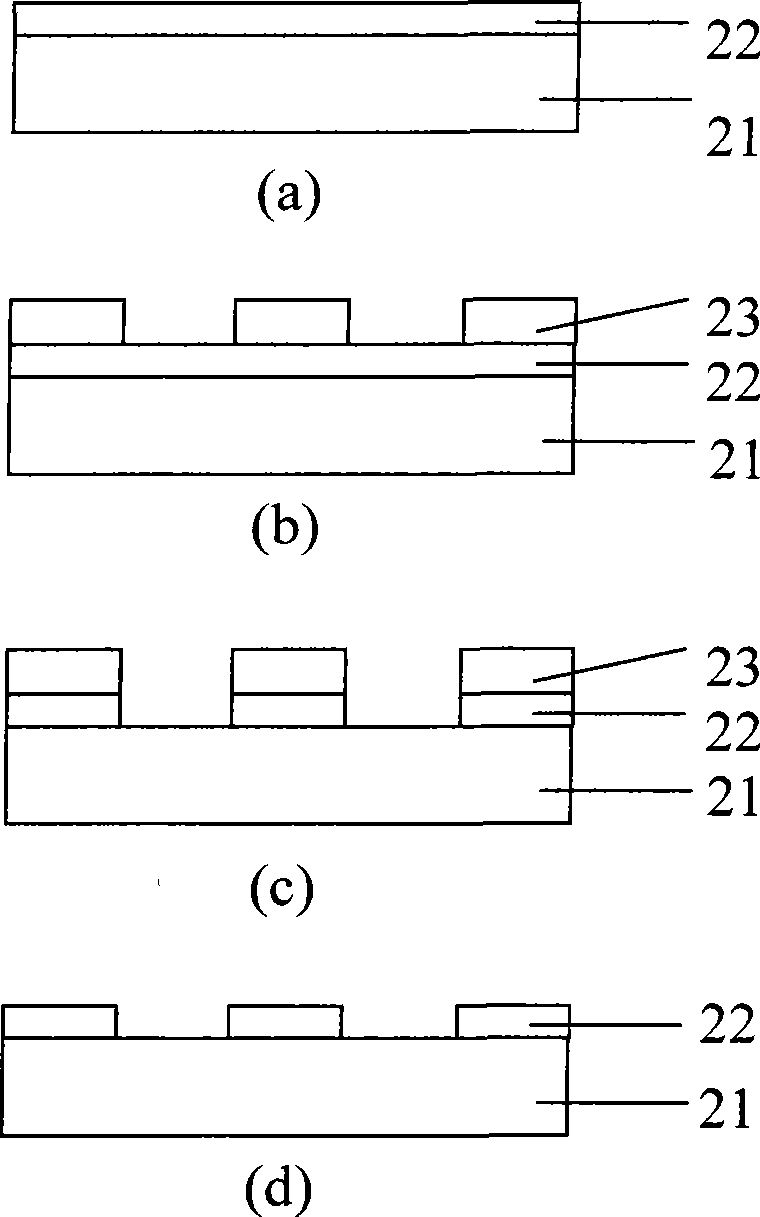

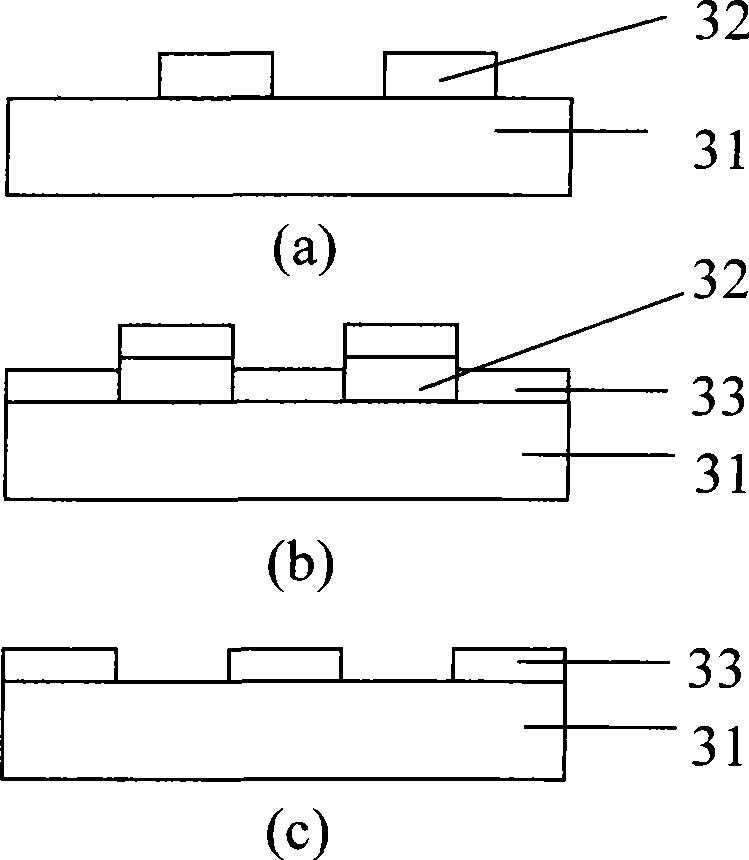

[0025] made as figure 1 The metal hole type high-power attenuator shown in the figure is usually used as figure 2 The shown process flow includes 4 process steps: (1) first coat a layer of metal film 22 on the glass substrate 21, and the attenuation of the metal film to light of 1310nm or 1550nm or other design wavelengths is usually greater than 60dB; 2) carry out the photolithography process then, coat photoresist 23 on the metal film surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com