Realization method for heat-engine plant speed regulating system model in power system simulation

A speed control system and power system technology, applied in general control systems, control/regulation systems, simulators, etc., can solve the problem that the speed control system model cannot interface, does not reflect the unit coordination control system model, and cannot reflect the speed control system dynamics Features and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

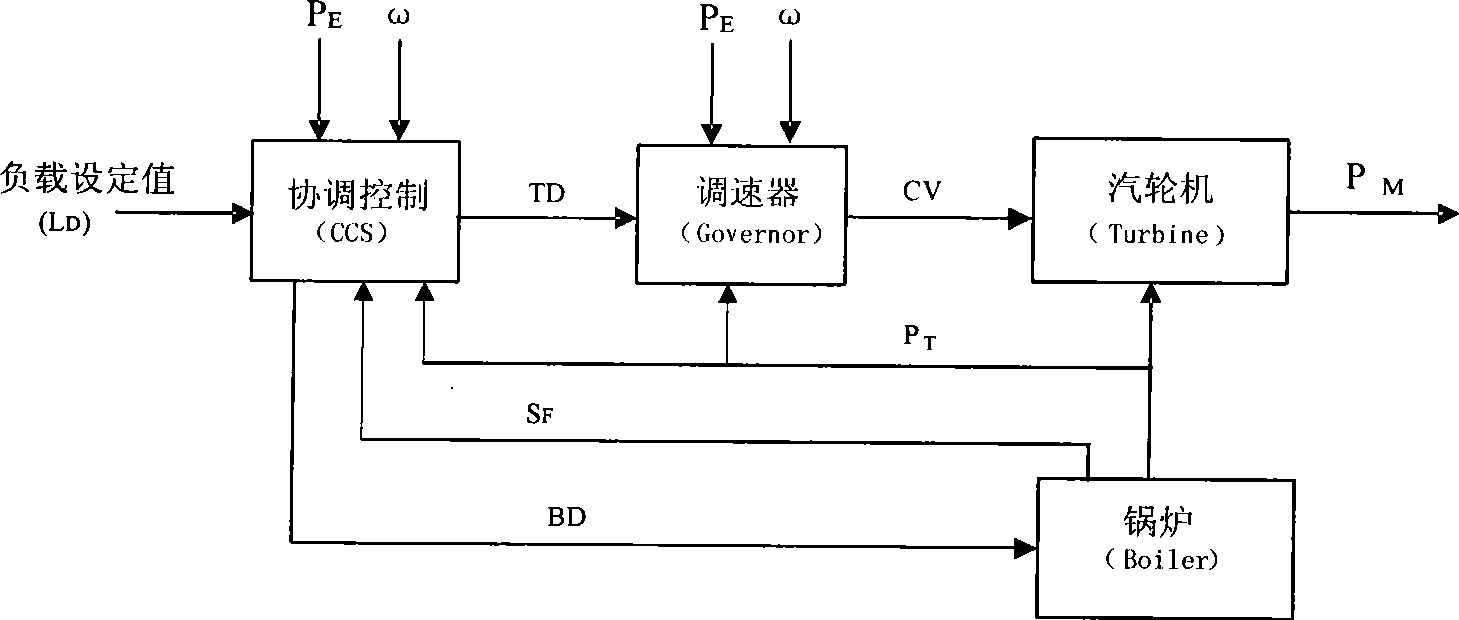

[0053] Below, refer to the attached Figure 4-8 Describe in detail the realization method of the thermal power plant speed regulation system model in the power system simulation of the present invention.

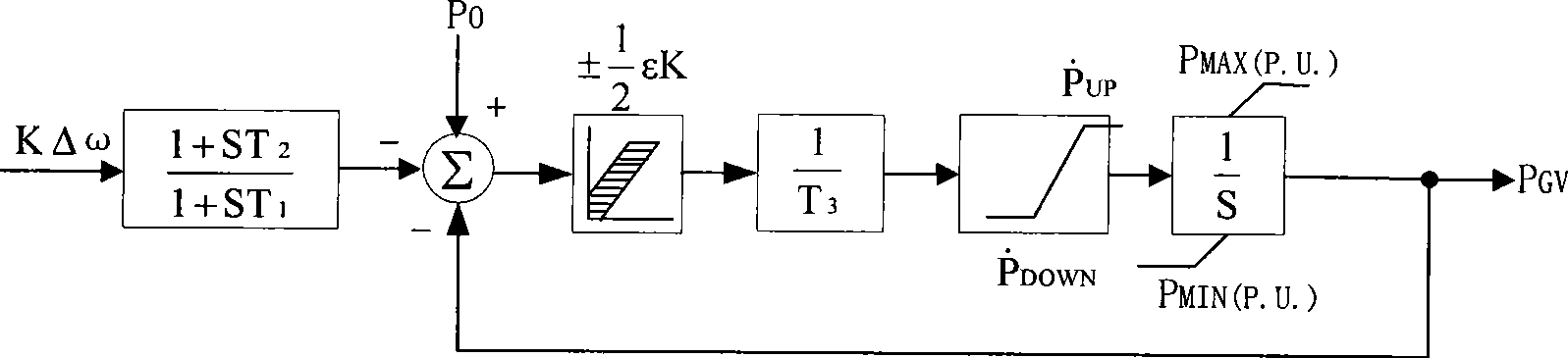

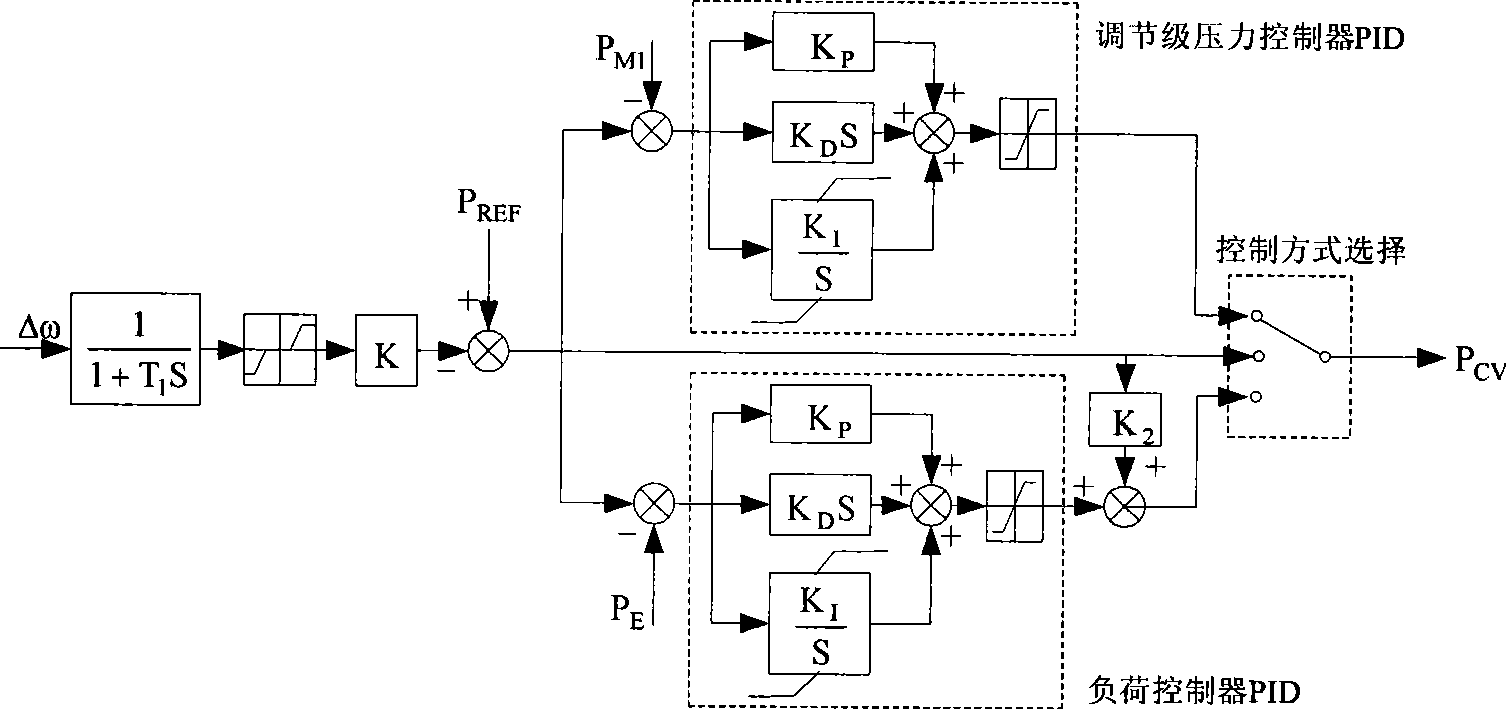

[0054] At present, most of the speed control system models of thermal power plants used in domestic power system stability simulations are similar to the typical models recommended by IEEE in 1973 (see attached figure 2 ), only simulating the steam turbine governor; although some regional power grids use the measured steam turbine governor model (see attached image 3 ), a model without a coordinated control part. However, the coordinated control system in thermal power plants has been widely used. If the dynamic characteristics of the coordinated control part are not considered, the characteristics of the speed regulation system in thermal power plants cannot be simulated accurately. Therefore, the present invention proposes a speed governing model with coordinated contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com