Halogen lamp and manufacturing method thereof

A production method and halogen lamp technology, which are applied to incandescent lamps, incandescent lamp parts, lead-in wires, etc., can solve the problem of high surface temperature, and achieve the effects of good light, low power consumption and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

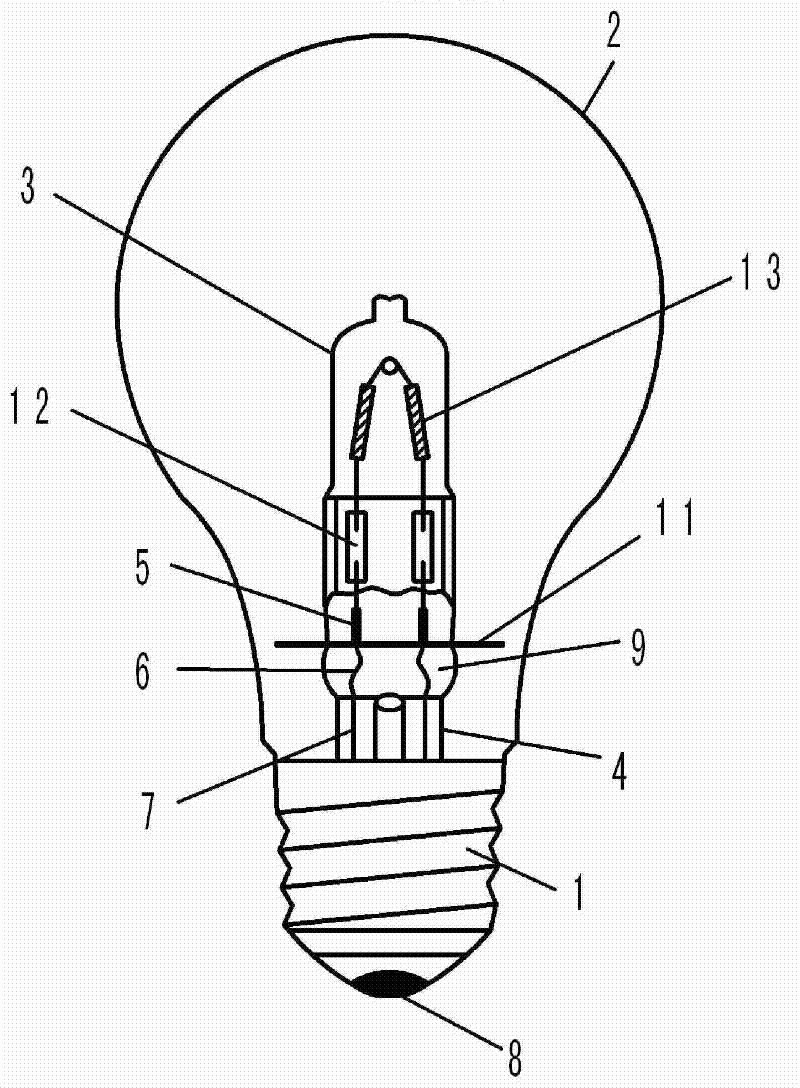

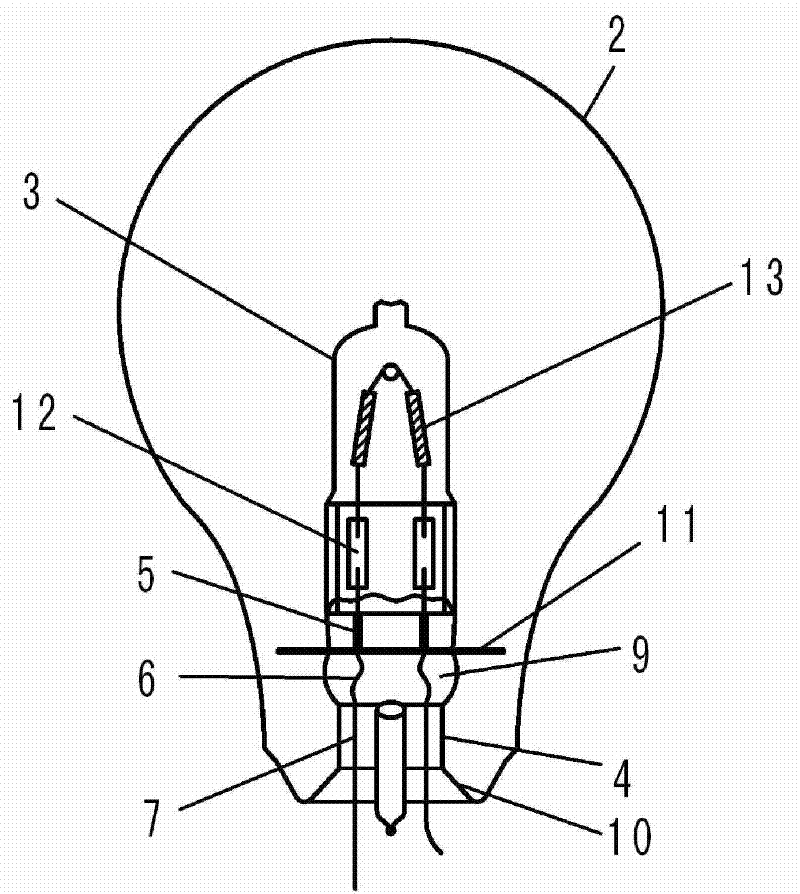

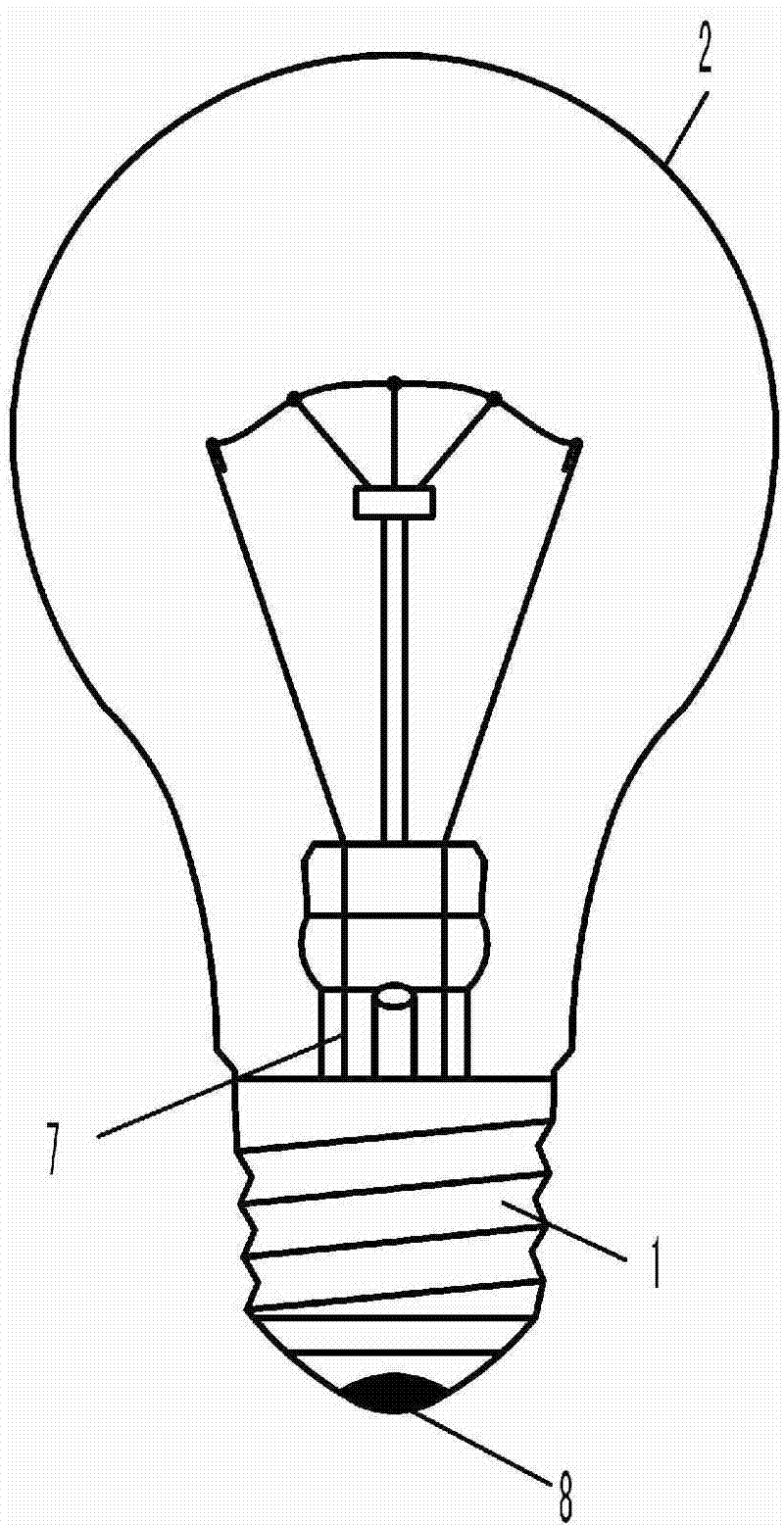

[0021] Example. Such as figure 1 and figure 2 As shown, it includes a lamp cap 1 and a glass bulb 2 connected to the lamp cap 1; a welding point 8 of the lamp cap 1; a halogen bulb 3 and a stem 4 are installed in the glass bulb 2; two lamp pins 5 are arranged on the halogen bulb 3, The lamp pin 5 is connected with the filament 13 through the molybdenum sheet 12 . The lamp pin 5 is made of nickel wire or molybdenum wire. Two connecting wires 6 and two copper guide wires 7 are arranged on the stem 4; the connecting wires 6 are made of du magnesium wire. The two lamp pins 5 are respectively directly connected to the two connecting wires 6, and the two lamp pins 5 and the two connecting wires 6 are sealed and packaged on the upper part of the stem 4, and the upper part of the stem 4 is provided with a flattened part 9, and the core The lower end of the column 4 is provided with a bell mouth 10, and the bell mouth 10 is sealed and connected with the glass bulb 2 as a whole aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com