Block body aluminum-based alloy and preparation method thereof

An aluminum-based alloy and bulk technology, which is applied in the field of high-strength and toughness Al-based alloys and their preparation, can solve the problems of inability to prepare millimeter-sized bulk Al-based amorphous alloys, and restrict the research and development of Al-based alloys, and achieves improved engineering. Application value, improvement of comprehensive mechanical performance indicators, and the effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

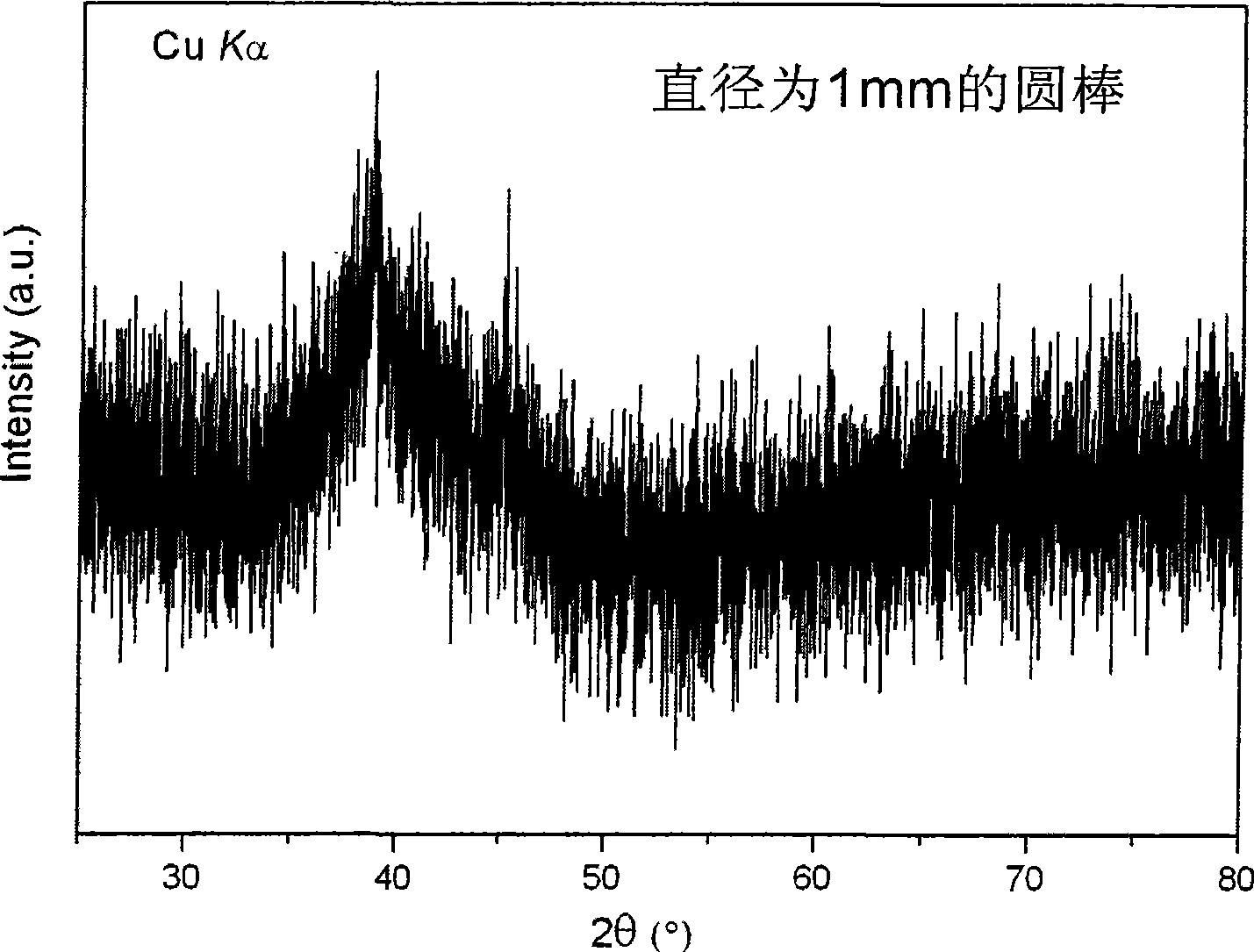

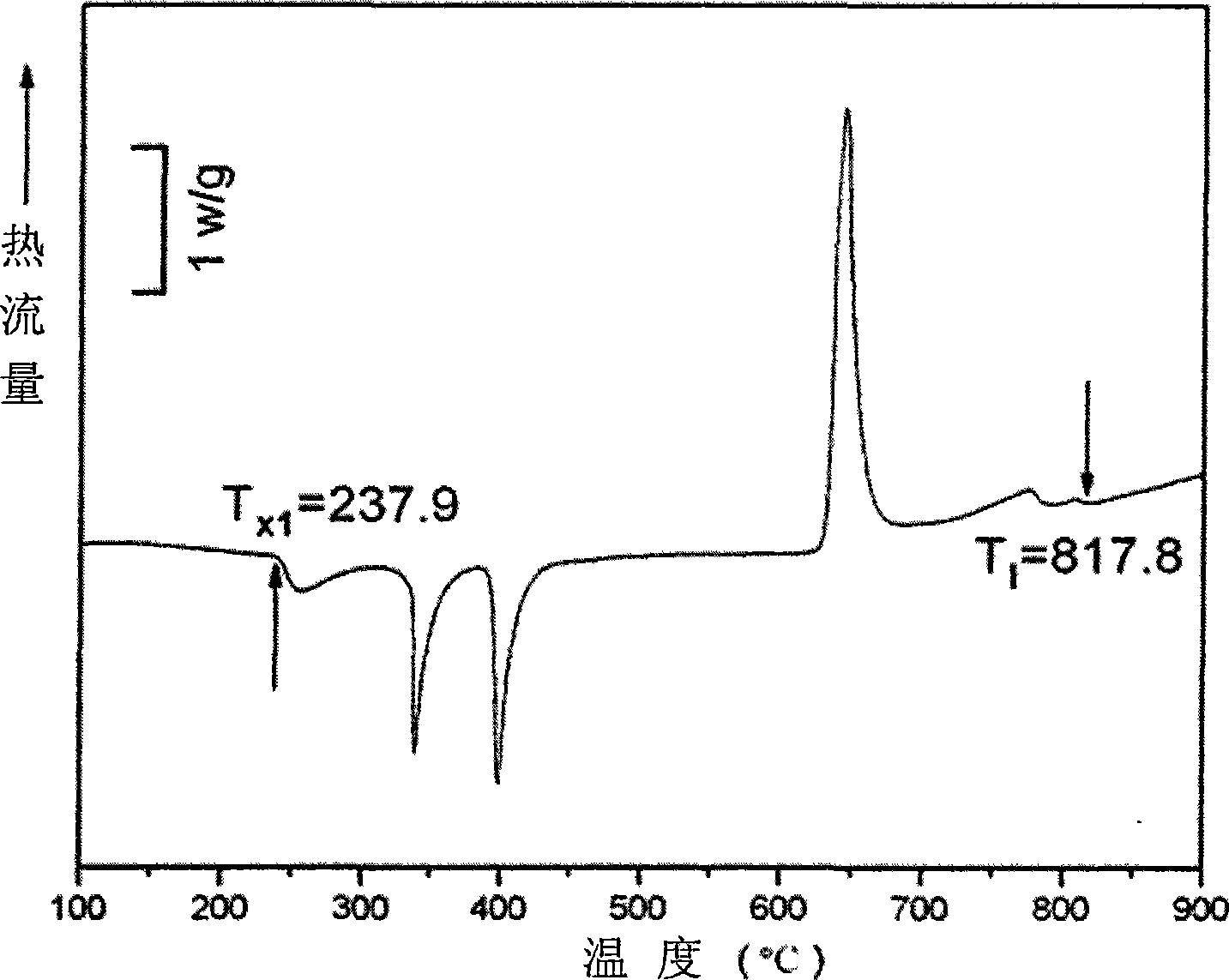

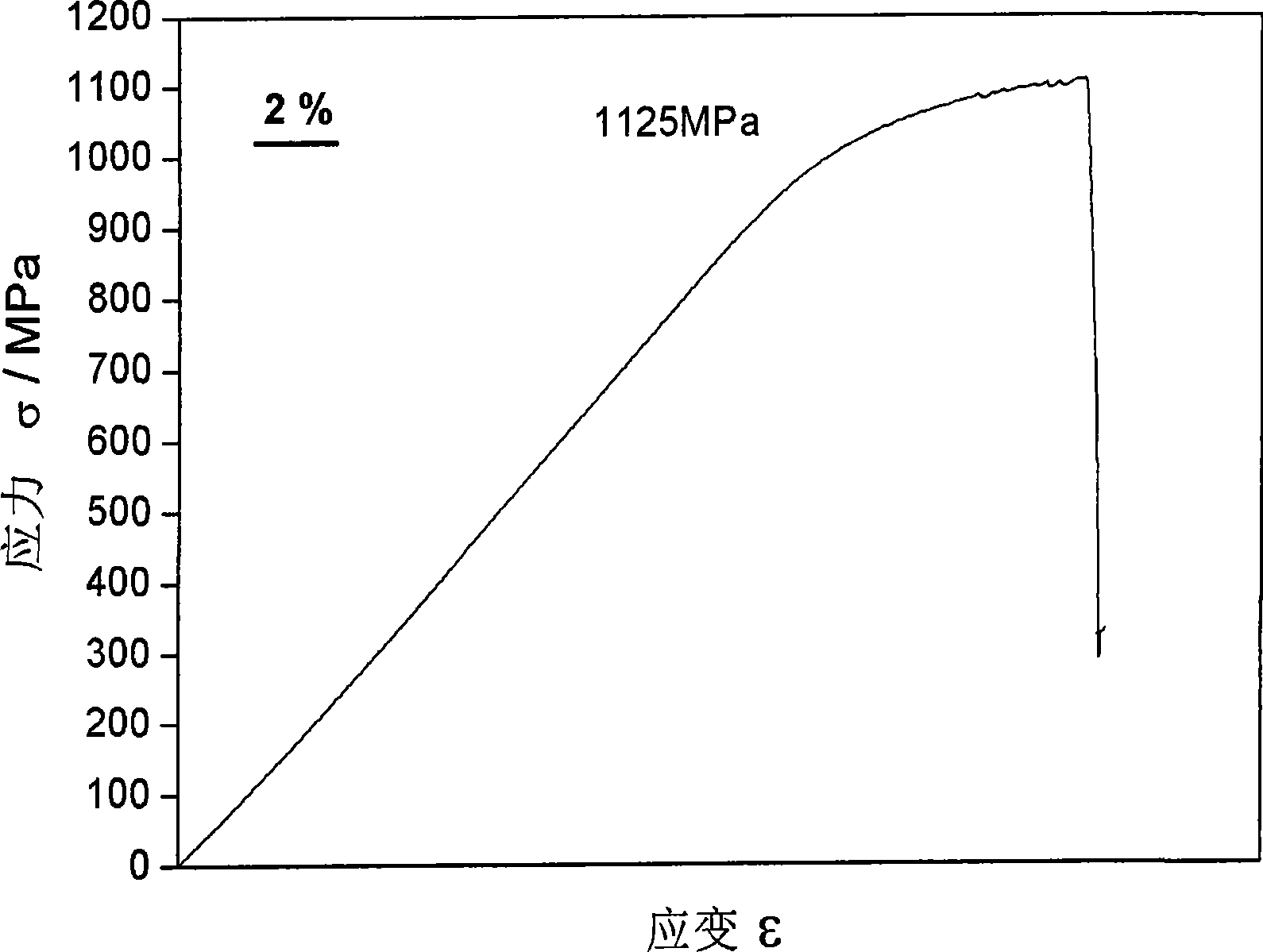

[0023] In this embodiment, TM is selected as a combination of transition metals Ni and Co; the percentage of atoms is 4 and 3 respectively; RE is the adjacent element Sc of element Y in the periodic table, and the percentage of atoms is 1; The percentage is 0.5; the percentage of Y atoms is 6; the rest is 85.5 of Al atoms, and the molecular formula of the obtained bulk aluminum-based alloy is Al 85.5 Si 0.5 Ni 4 co 3 Y 6 sc 1 .

[0024] The bulk alloy Al in this example 85.5 Si 0.5 Ni 4 co 3 Y 6 sc 1 The preparation method is as follows:

[0025] Step 1: Press Al 85.5 Si 0.5 Ni 4 co 3 Y 6 sc 1 Chemical composition ratio for batching;

[0026] Press Al 85.5 Si 0.5 Ni 4 co 3 Y 6 sc 1 Calculate and weigh the corresponding raw material quality;

[0027] Step 2: Melting to prepare Al 85.5 Si 0.5 Ni 4 co 3 Y 6 sc 1 master alloy;

[0028] Put the raw materials of the target ingredients weighed in step 1 into the vacuum arc melting furnace, and vacuumiz...

Embodiment 2

[0032] In this embodiment, TM is selected as a combination of transition metals Ni and Ag; the percentages of atoms are 1 and 1 respectively; the percentages of Si atoms are 5; the percentages of Y atoms are 10; the rest are the percentages of Al atoms is 83, and the molecular formula of the obtained bulk aluminum-based alloy is Al 83 Si 5 Ni 1 Ag 1 Y 10 .

[0033] The bulk alloy Al in this example 83 Si 5 Ni 1 Ag 1 Y 10 The preparation method is as follows:

[0034] Step 1: Press Al 83 Si 5 Ni 1 Ag 1 Y 10 Chemical composition ratio for batching;

[0035] Press Al 83 Si 5 Ni 1 Ag 1 Y 10 Calculate and weigh the corresponding raw material quality;

[0036] Step 2: Melting to prepare Al 83 Si 5 Ni 1 Ag 1 Y 10 master alloy;

[0037] Put the raw materials of the target ingredients weighed in step 1 into the vacuum arc melting furnace, and vacuumize to 1-5×10 -3 Pa, filled with argon protective gas at a pressure of 0.02-0.09MPa; adjusted current 200-350A,...

Embodiment 3

[0041] This embodiment selects TM to be the combination of transition metals Ni, Co and Ag; the percentage of atoms is 3, 3 and 2 respectively; RE is the adjacent element Ca in the periodic table of element Y and La in the La series rare earth Combination, the percentages of atoms are 2 and 3 respectively; the percentage of Si atoms is 1; the percentage of Y atoms is 6; the rest is 80% of Al atoms, the molecular formula of the obtained bulk aluminum-based alloy is Al 80 Si 1 Ni 3 co 3 Ag 2 Y 6 Ca 2 La 3 .

[0042] The bulk alloy Al in this example 80 Si 1 Ni 3 co 3 Ag 2 Y 6 Ca 2 La 3 The preparation method is as follows:

[0043] Step 1: Press Al 80 Si 1 Ni 3 co 3 Ag 2 Y 6 Ca 2 La 3 Chemical composition ratio for batching;

[0044] Press Al 80 Si 1 Ni 3 co 3 Ag 2 Y 6 Ca 2 La 3 Calculate and weigh the corresponding raw material quality;

[0045] Step 2: Melting to prepare Al 80 Si 1 Ni 3 co 3 Ag 2 Y 6 Ca 2 La 3 master alloy;

[0046] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com