Building board construction support with variable size

A kind of building board, variable technology, applied in the direction of construction, building construction, etc., can solve the problems of labor-intensive pasting and leveling process, roughness, and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

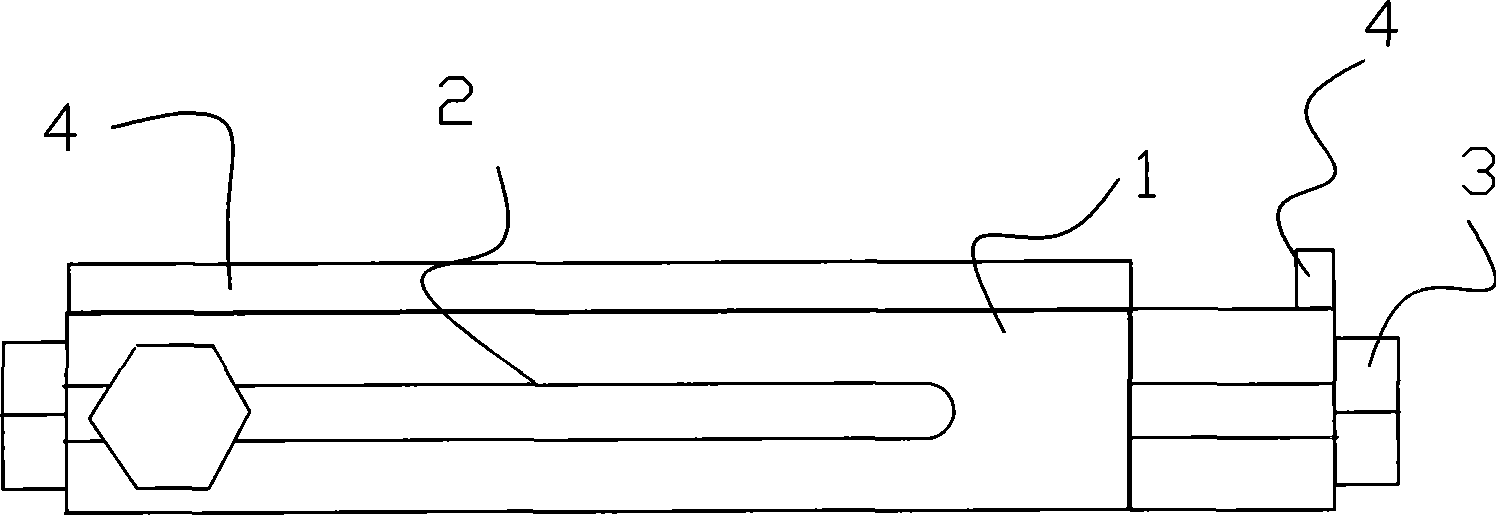

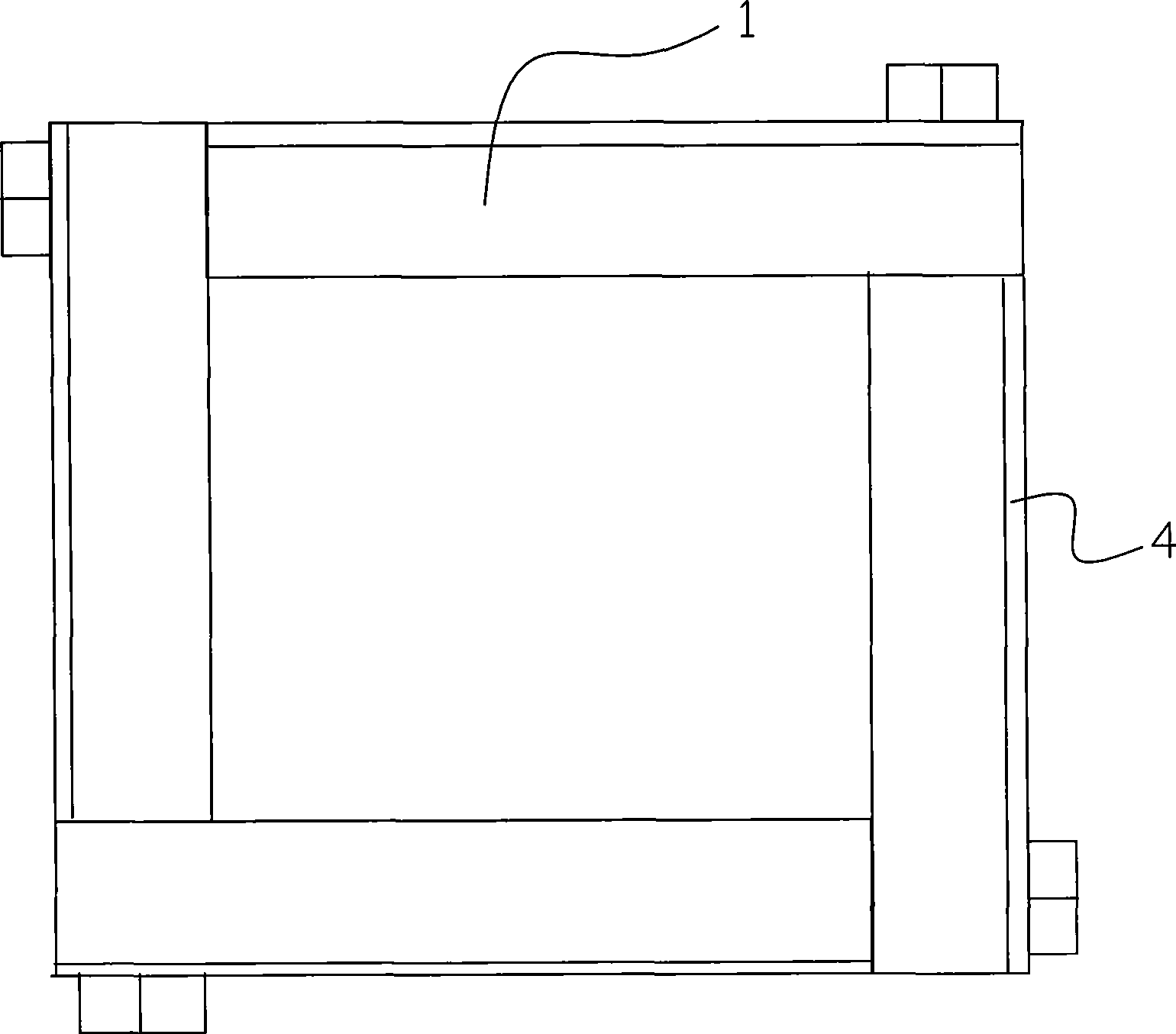

[0030] Such as figure 1 , 2 As shown, the telescopic building board construction support of the present invention is made up of 4 identical components 1, and component 1 is a rectangular parallelepiped metal rod with a square cross section. One end of the metal rod has a U-shaped through groove 2, and the other end has a Threaded hole, the bolt 3 is inserted into the U-shaped through groove 2 of one component 1 and then screwed into the threaded hole of the other component 1 to form figure 2 bracket shown. The upper and lower ends of the bracket are flat, which is convenient for placing the wall decoration board and applying glue.

[0031] When the size of the decorative plate used is changed, unscrew the bolt and slide to the closed end along the U-shaped through groove 2 of the component 1, so that the size of the frame surrounded by the four components can be changed to adapt to decorative plates of different sizes.

[0032] Similarly, a screw rod can also be arranged a...

Embodiment 2

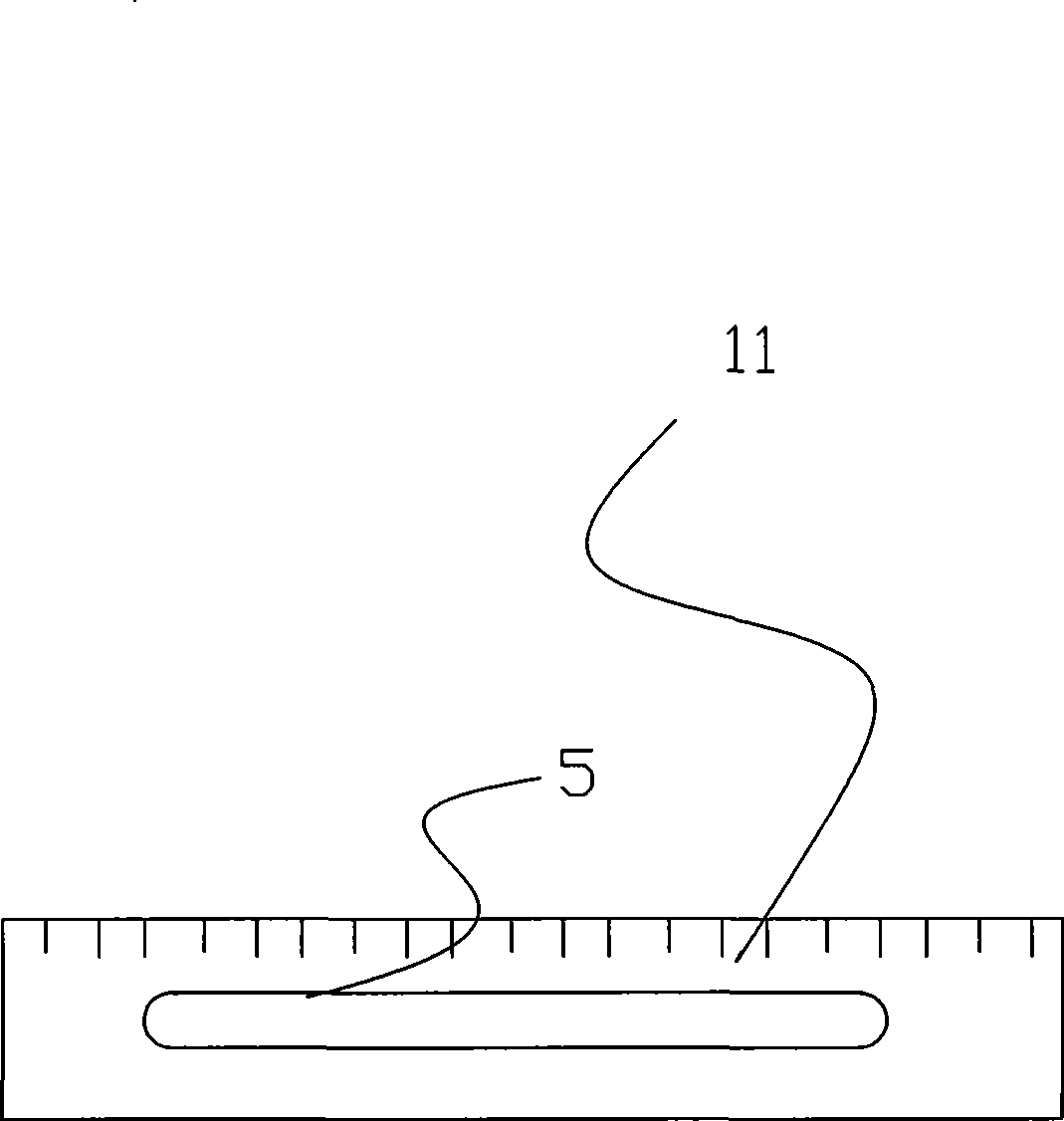

[0039] Such as image 3 Shown is another embodiment of the present invention, the component 11 has a strip-shaped through hole 5 along the middle of the length direction, and the bolt is inserted into the strip-shaped through hole 5 and then screwed into the threaded hole of another component to form a rectangular frame, which is convenient for gluing . By sliding the bolt along the strip-shaped through hole 5, the size of the formed frame can be changed, so as to be suitable for wall decoration boards of different sizes.

[0040] After use, the components are disassembled, which is convenient for transportation and storage.

[0041] The bracket can be made of light metal such as aluminum to reduce its own weight, or it can also be made of plastic and other materials, and the cost is lower.

[0042] The bracket is suitable for gluing operations on various boards such as decorative boards and insulating boards.

Embodiment 3

[0044] Such as figure 1 , 2 As shown in and 4, there is also a strip-shaped protrusion 4 on the outer side of the upper surface of the component 1, and the height of the protrusion 4 can be adjusted along the up and down direction, so that the thickness of the glue can be conveniently controlled, the assembly line is convenient, and the efficiency of gluing has been improved. Ensure the smoothness of the glue coating.

[0045] Such as Figure 5 As shown, when in use, adjust the size of the bracket according to the size of the board, and after fixing, place the board 10 on the bracket. It can not only fix the board, but also control the thickness of the glue.

[0046] The bracket is suitable for gluing operations on various boards such as decorative boards and insulating boards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com