Inspection method and inspection apparatus of display panel

A display panel and inspection method technology, applied in the direction of measuring devices, optics, instruments, etc., can solve the problems of optical axis deviation, poor inspection efficiency, complex image processing procedures, etc., and achieve the effect of high-precision inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0035] A first embodiment of the present invention will be described below.

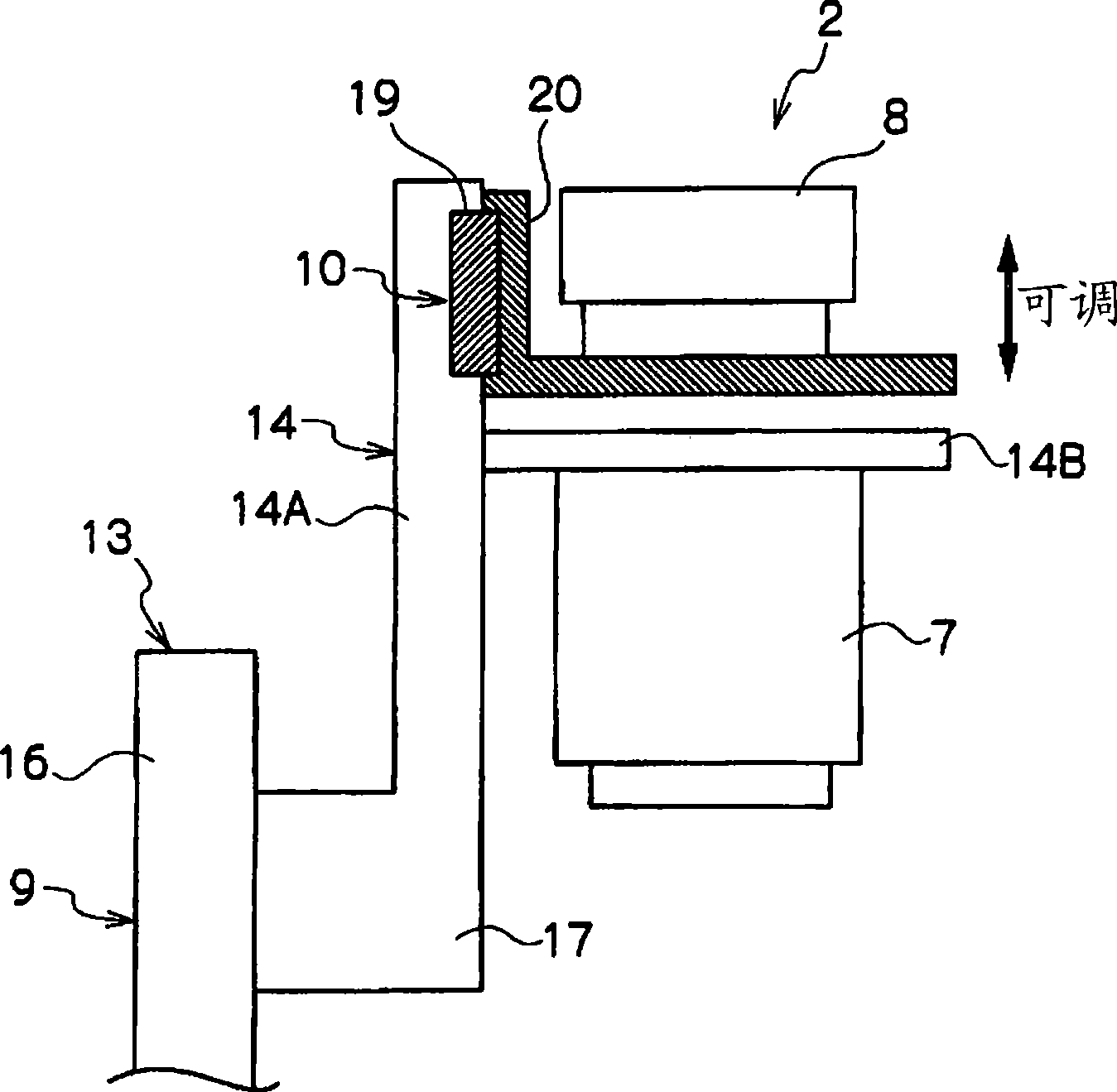

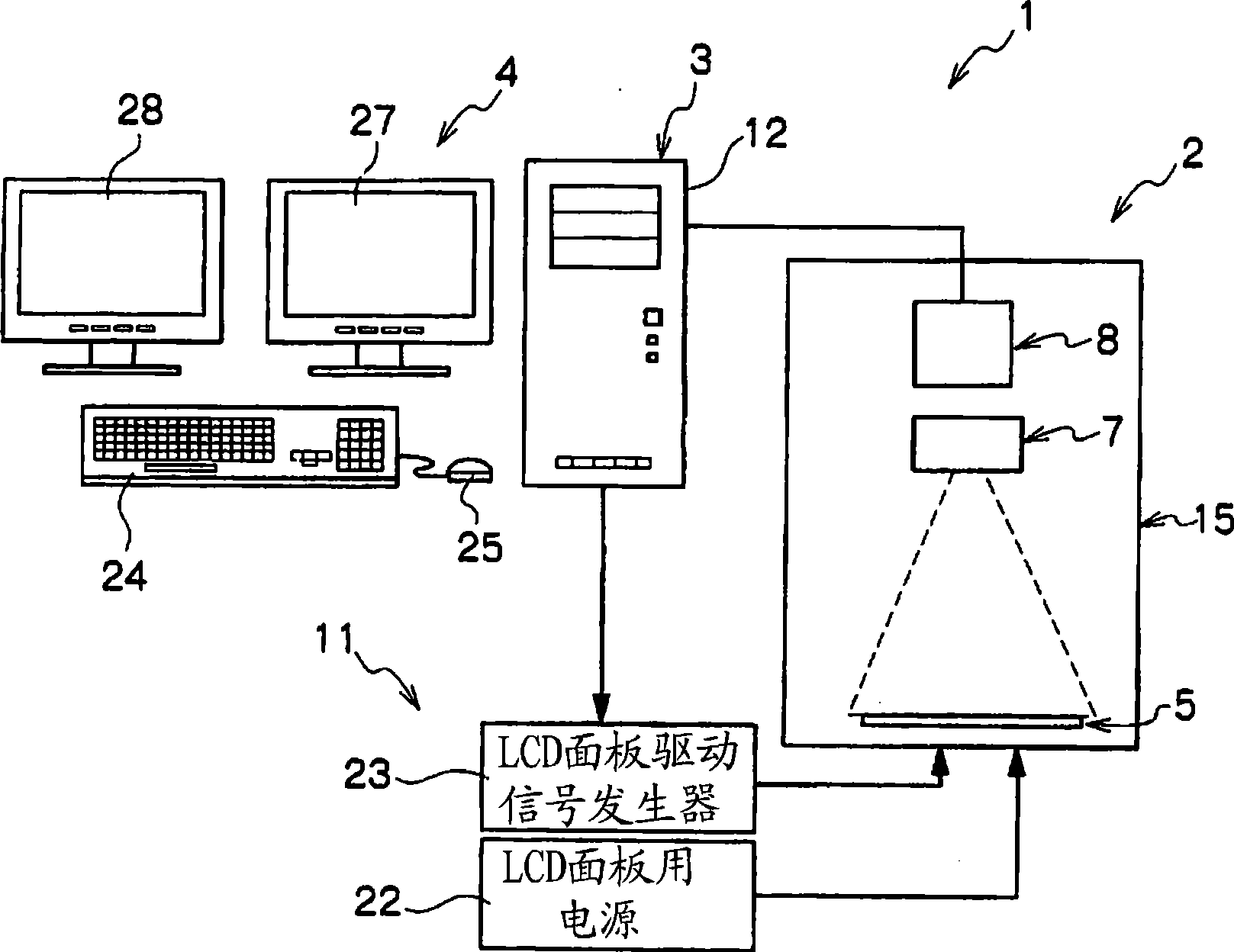

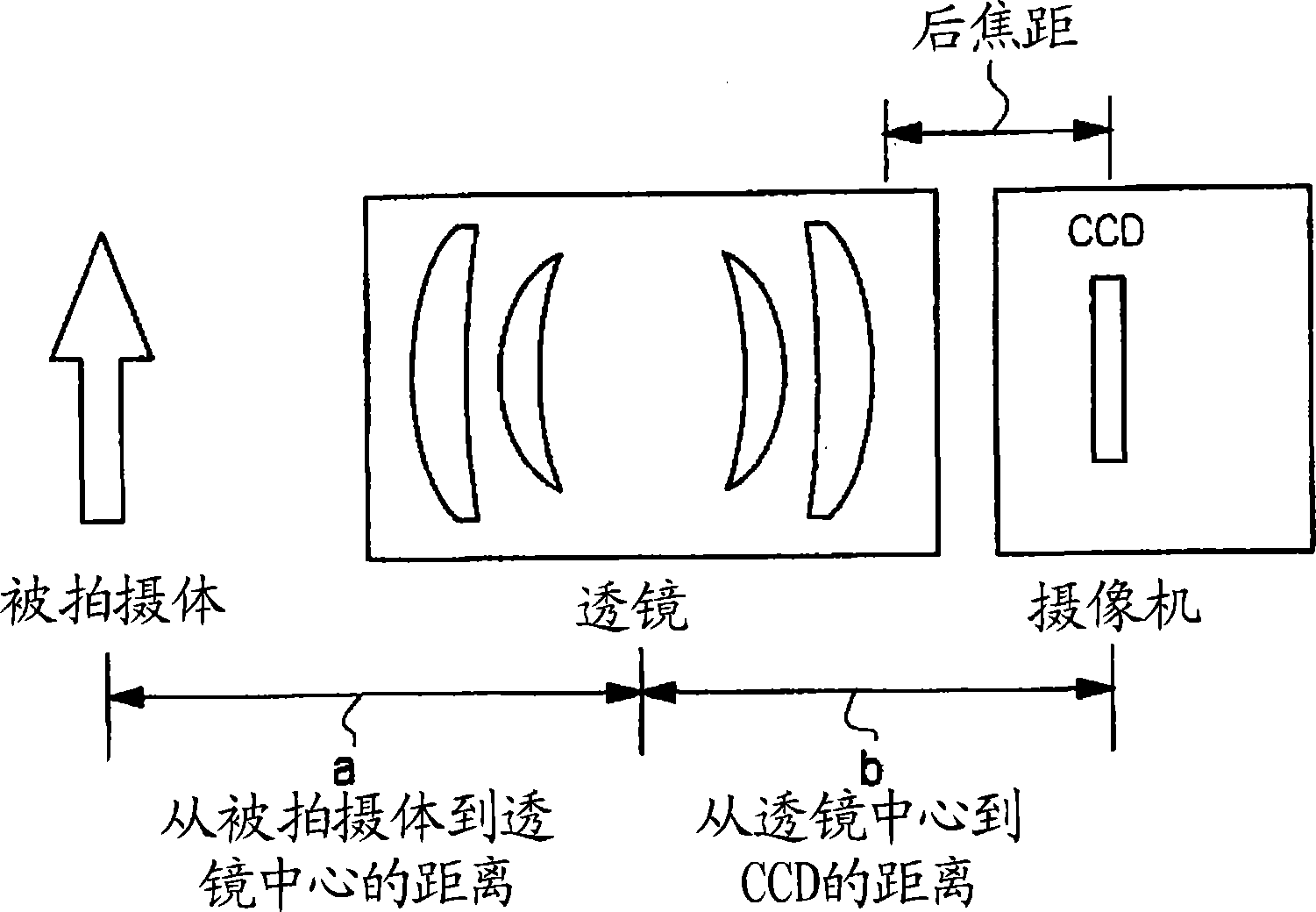

[0036] figure 1 is a configuration diagram schematically showing the imaging device of the display panel inspection device according to the embodiment of the present invention, figure 2 is a diagram schematically showing the structure of a display panel inspection device, image 3 It is an explanatory diagram schematically showing the focal length with respect to the front focal length and the back focal length of the imaging device according to the embodiment of the present invention, Figure 4 It is a graph schematically showing the brightness level distribution of the light detected by each pixel of the CCD element when the display panel is photographed by the imaging device, Figure 5 It is a graph schematically showing the brightness level distribution of the light detected by each pixel of the CCD element when the display panel is photographed by the imaging device in the state where moiré f...

no. 2 Embodiment approach

[0081] A second embodiment of the present invention will be described below.

[0082] The display panel inspection device of the present embodiment adds an optical filter to the display panel inspection device 1 of the first embodiment described above. Since the overall configuration is the same as that of the display panel inspection apparatus 1 according to the first embodiment, the same components are given the same reference numerals here, and description thereof will be omitted, and the description will focus on the optical filter.

[0083] like Figure 9 As shown, the display panel inspection apparatus according to this embodiment is provided with a filter mounting section 31 for mounting an optical filter 30 between the lens system 7 of the imaging device 2 and the imaging element 8 .

[0084] As the optical filter 30, a filter having functions required for a display panel inspection device is used. For example, select the one required for a display panel inspection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com