Light emitting unit

A light-emitting unit and light-emitting diode technology, which is applied in the direction of electrical components, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems of not being able to improve the heat dissipation of light-emitting diodes, and achieve the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

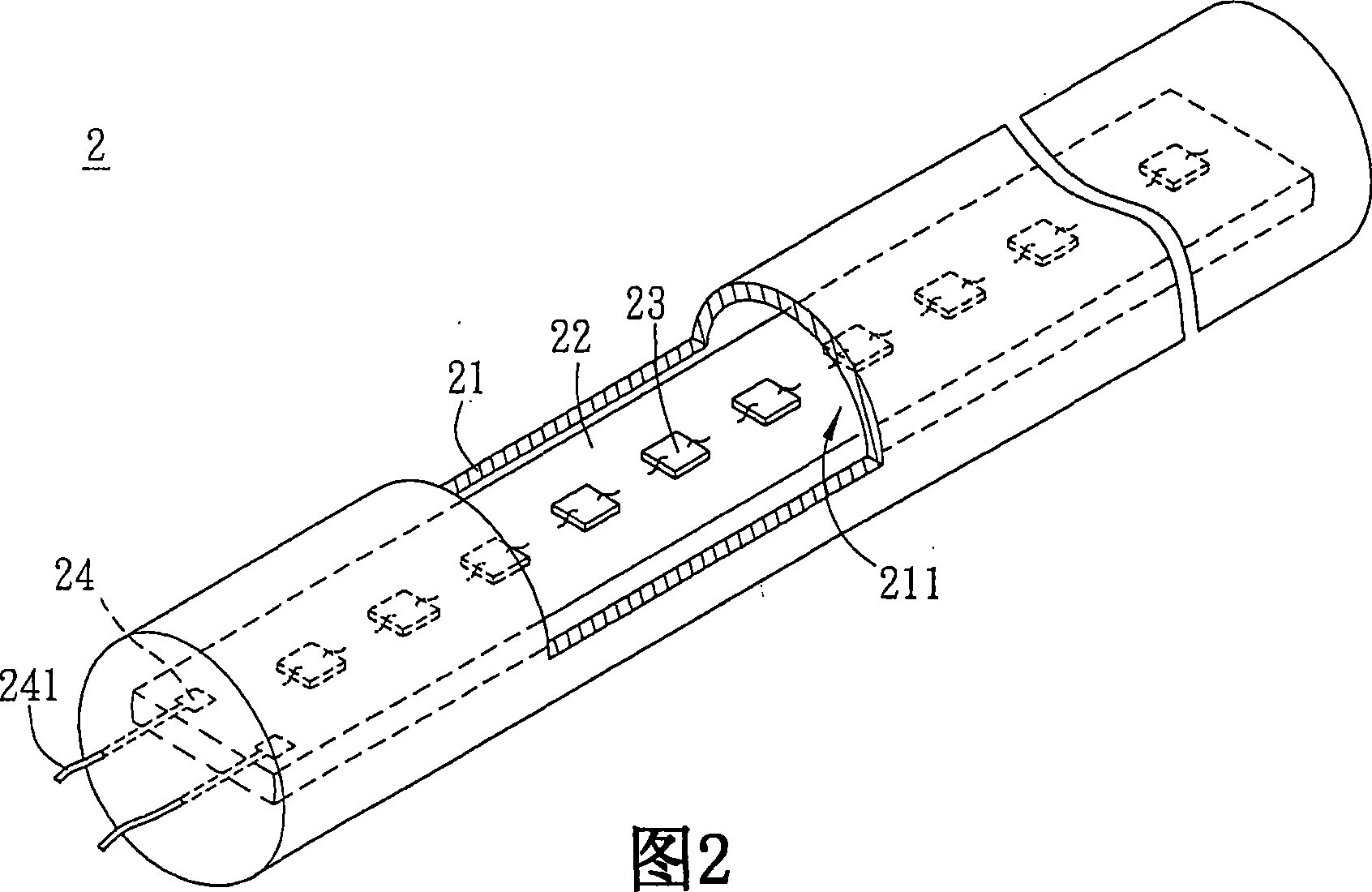

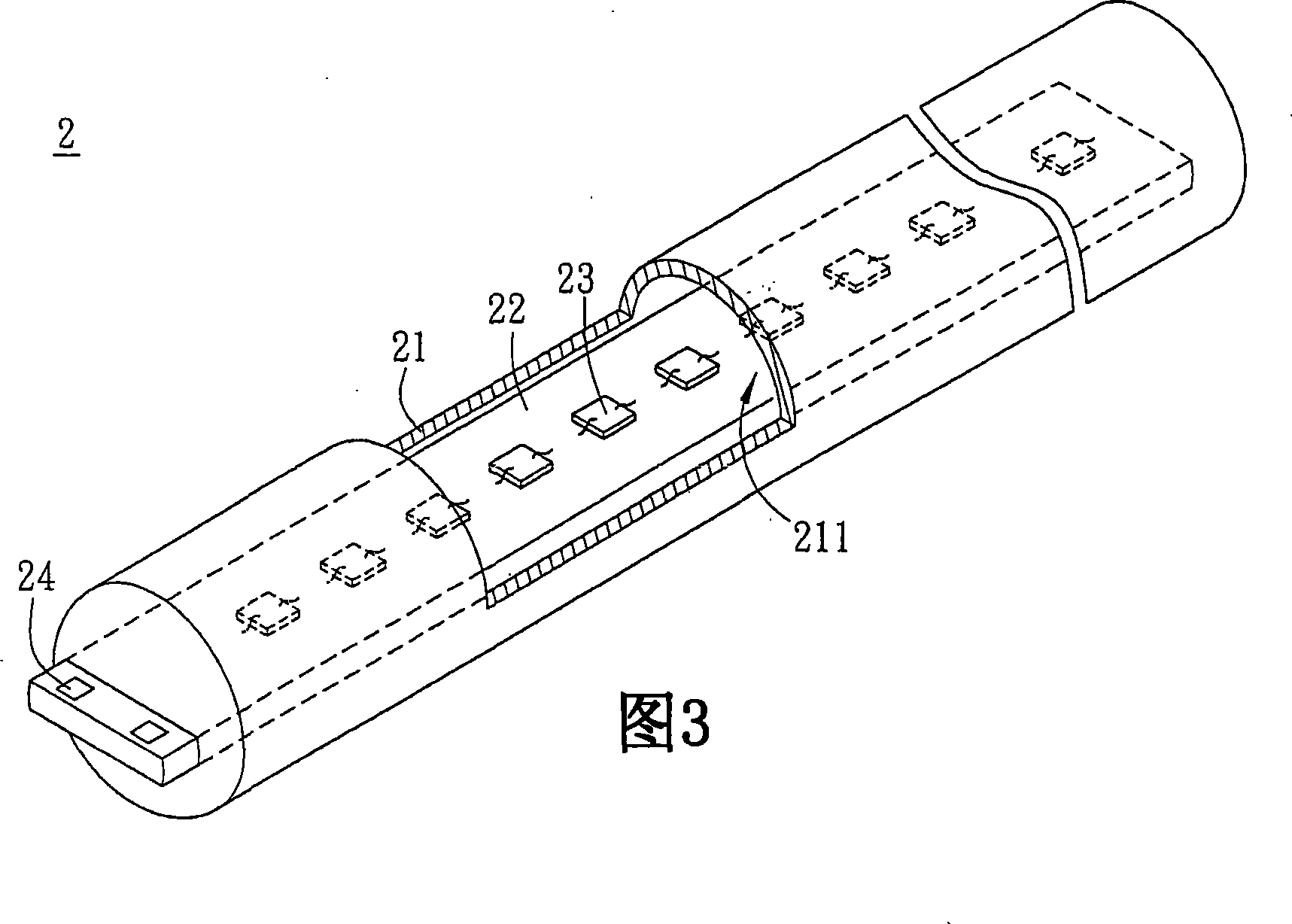

[0045] Referring to FIG. 2 , a light-emitting unit 2 according to the first embodiment of the present invention includes a light-transmitting tube body 21 , a circuit board 22 , a plurality of LED chips 23 and at least two connecting electrodes 24 .

[0046] The transparent tube body 21 is at least partly transparent and has a closed space 211. In other words, the transparent tube body 21 can have a transparent part and a non-transparent part, which means that the transparent tube body 21 can be partly transparent and partly Opaque, of course, the light-transmitting tube body 21 can also be completely light-transmitting. The enclosed space 211 can be vacuum or filled with gas, such as inert gas or nitrogen. In addition, the closed space 211 can also be filled with a colloid or a fluid, wherein the colloid is, for example, a liquid colloid or an elastic colloid, and the fluid is, for example, an oily fluid, and the refractive index of the liquid colloid, elastic colloid or oily...

no. 2 example

[0057] Please refer to Figure 5A and Figure 5B shown, where Figure 5B It is a sectional view along the line A-A in Fig. 5A. The difference between the light emitting unit 2A of the second embodiment of the present invention and the first embodiment is that the light emitting unit 2A further includes a reflective portion and a fluorescent conversion material 26 . Wherein, the reflective portion can be a part of the light-transmitting tube body 21 , or a reflective layer 25 can be added as described in this embodiment.

[0058] In this embodiment, the reflective layer 25 is disposed on the outer surface of the transparent tube body 21 and has at least one opening 251 corresponding to a light emitting surface of the LED die 23 . The material of the reflective layer 25 is selected from one of the ultraviolet light band (200-400nm), the visible blue light band (400-480nm) or the full visible light band (400-780nm) in the reflection spectrum, and its reflectivity is at least gre...

no. 3 example

[0070] Based on the above, the light-transmitting tube body of the light-emitting unit can be formed integrally as described above, and can also be composed of at least two shell elements. Please refer to Figure 10A and Figure 10B As shown, a light-transmitting tube body 41 of the light emitting unit 4 is composed of two shell elements 412 , 413 . A plurality of LED chips 43 and two connecting electrodes 44 are also disposed on the circuit substrate 42 , and the circuit substrate 42 is sandwiched between the two housing components 412 , 413 . Wherein, a reflective layer 45 can be arranged or formed on the circuit substrate 42, and a fluorescent conversion material 46 can be arranged or formed on the casing element 412, but it is not limiting, and its variations can also refer to the above-mentioned Example. In addition, since the light-transmitting tube body 41 can have a light-transmitting portion and a non-light-transmitting portion, which means that it can be partly li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com