Bonding material, electronic component, bonding structure and electronic device

A technology for bonding materials and electronic components, applied in welding equipment, welding/cutting media/materials, and assembling printed circuits with electrical components, etc., can solve problems such as inability to obtain bismuth alloys, and achieve the effect of suppressing poor quality and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] [joining material]

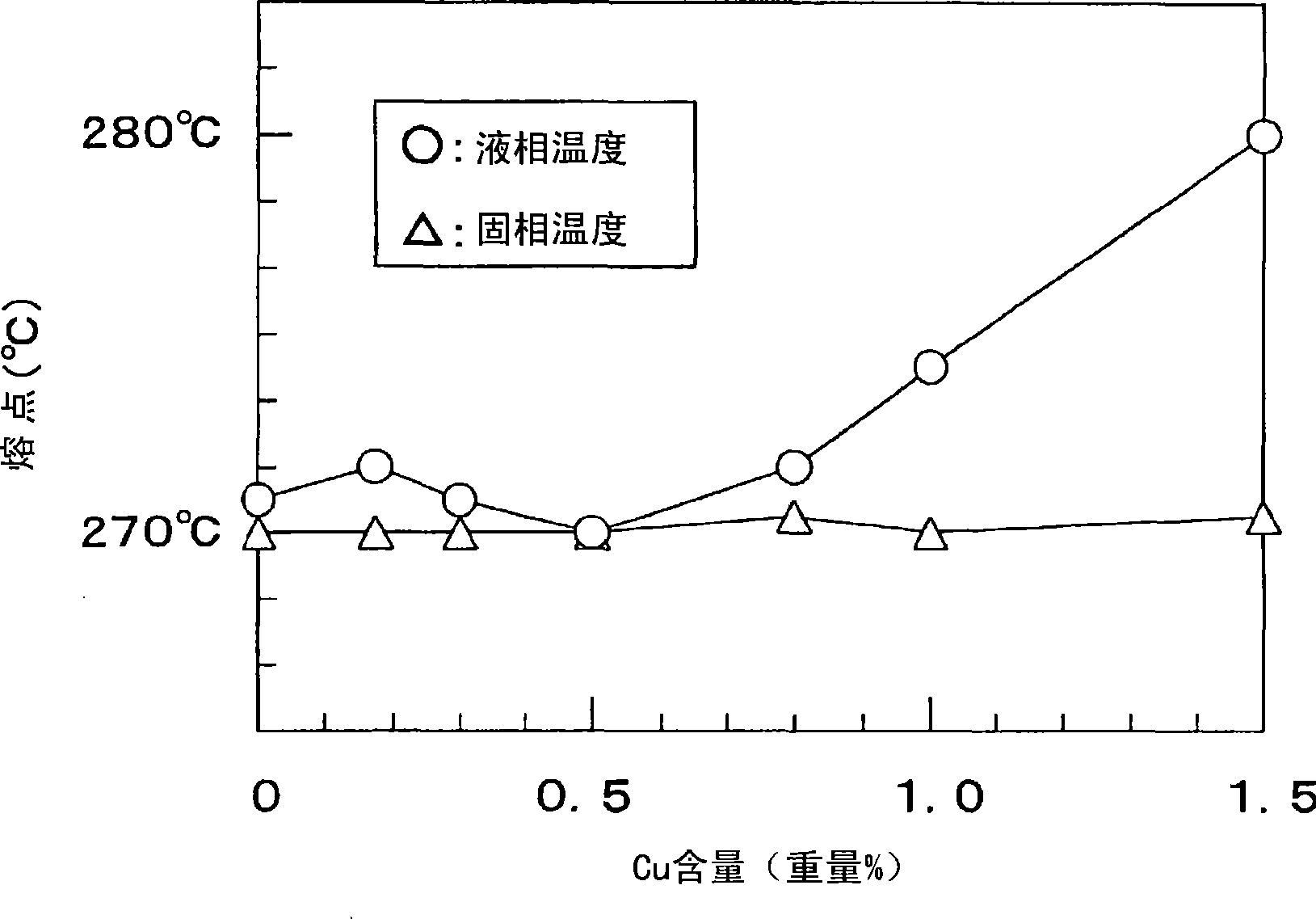

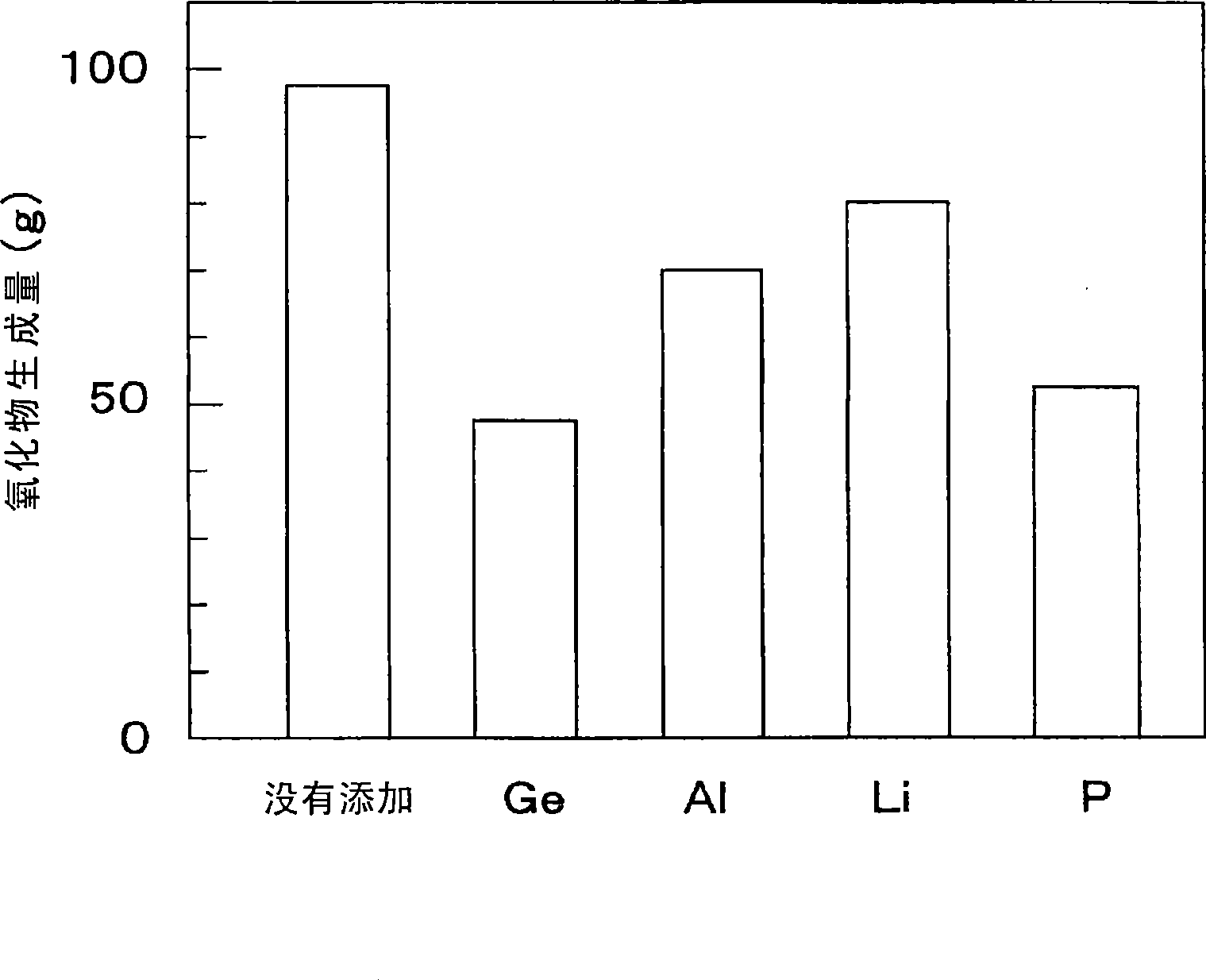

[0048] The bonding material (1) of the present invention is characterized by containing a bismuth alloy (1) containing Cu and Ge, the balance being Bi, and further containing unavoidable impurities, and containing no lead. In the Bi alloy (1), the Cu content is 0.2 to 0.8 wt%, preferably 0.4 to 0.6 wt%, of the total amount of the bismuth alloy (1). The Ge content is 0.02 to 0.2% by weight of the total amount of the bismuth alloy (1), preferably 0.02 to 0.05% by weight.

[0049] The bonding material (2) of the present invention is characterized by containing a bismuth alloy (2) containing Cu, Ge, and Ni, the remainder being Bi, and further containing unavoidable impurities, and containing no lead.

[0050] In the bismuth alloy (2), the Cu content is 0.2-0.8% by weight of the total amount of the bismuth alloy (2), preferably 0.4-0.6% by weight. The Ge content is 0.02 to 0.2% by weight of the total amount of the bismuth alloy (2), preferably 0.02 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com