Vehicle-bridge automatic water-cooling apparatus

A water-cooling device and axle technology, applied in the directions of brakes, vehicle parts, transportation and packaging, can solve the problem of not being able to detect the temperature of the axle in time, and achieve the effects of avoiding bearing burnout, easy processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

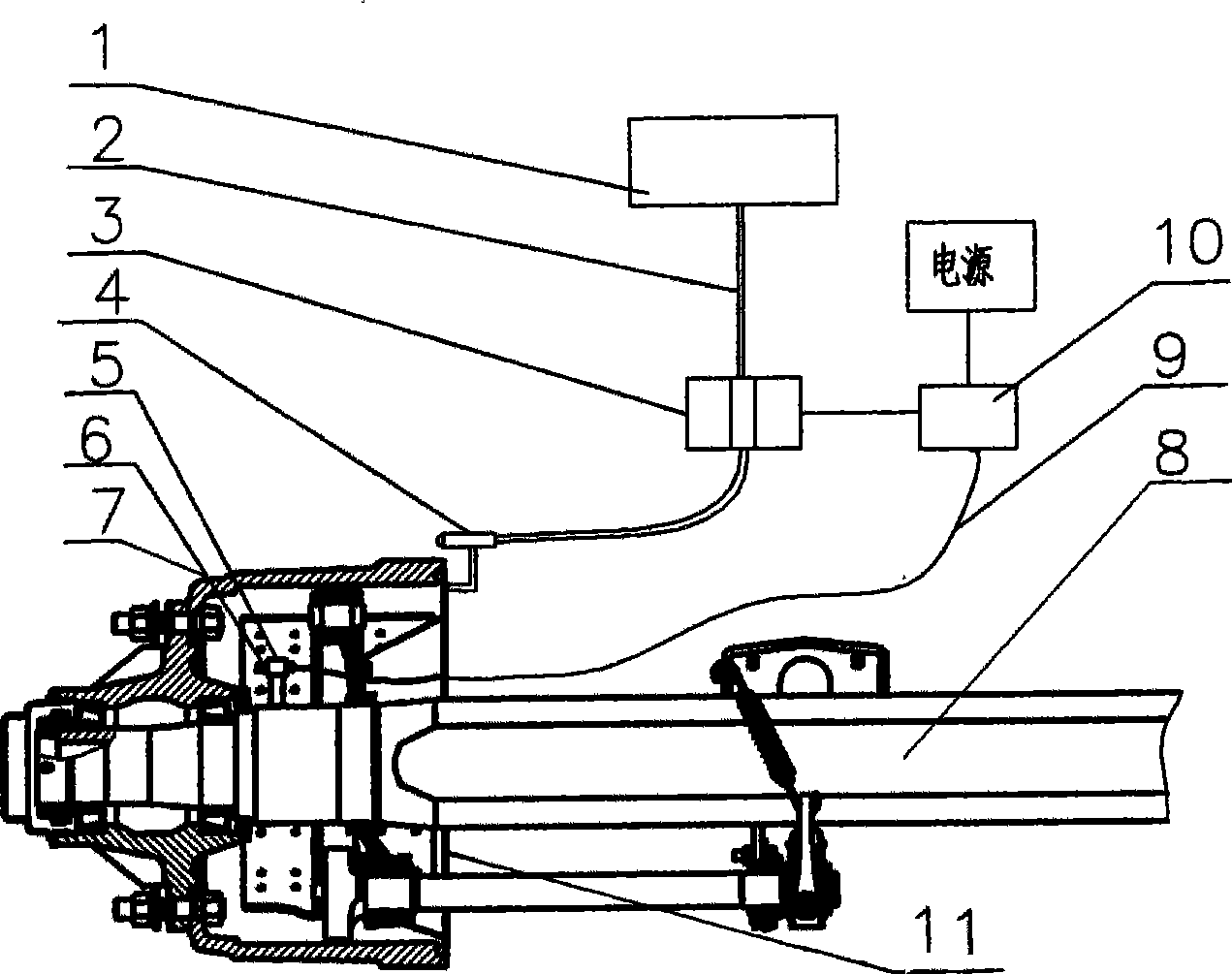

[0012] Depend on figure 1 It can be seen that the solenoid valve 3 and the nozzle 4 are connected to the water tank 1 by the water pipe 2, the nozzle 4 is fixed on the axle dust cover 11, facing the brake drum 5, the temperature sensor 7 is fixed on the mounting seat 8, and the mounting seat 8 is fixed on the on axle 6. The temperature sensor 7 is connected with the amplifying circuit 10 by the wire 9, and the amplifying circuit 10 is electrically connected with the solenoid valve 3 respectively. When the temperature of the axle is abnormal, the electromagnetic valve DF is opened, and the nozzle 4 sprays water to cool the axle.

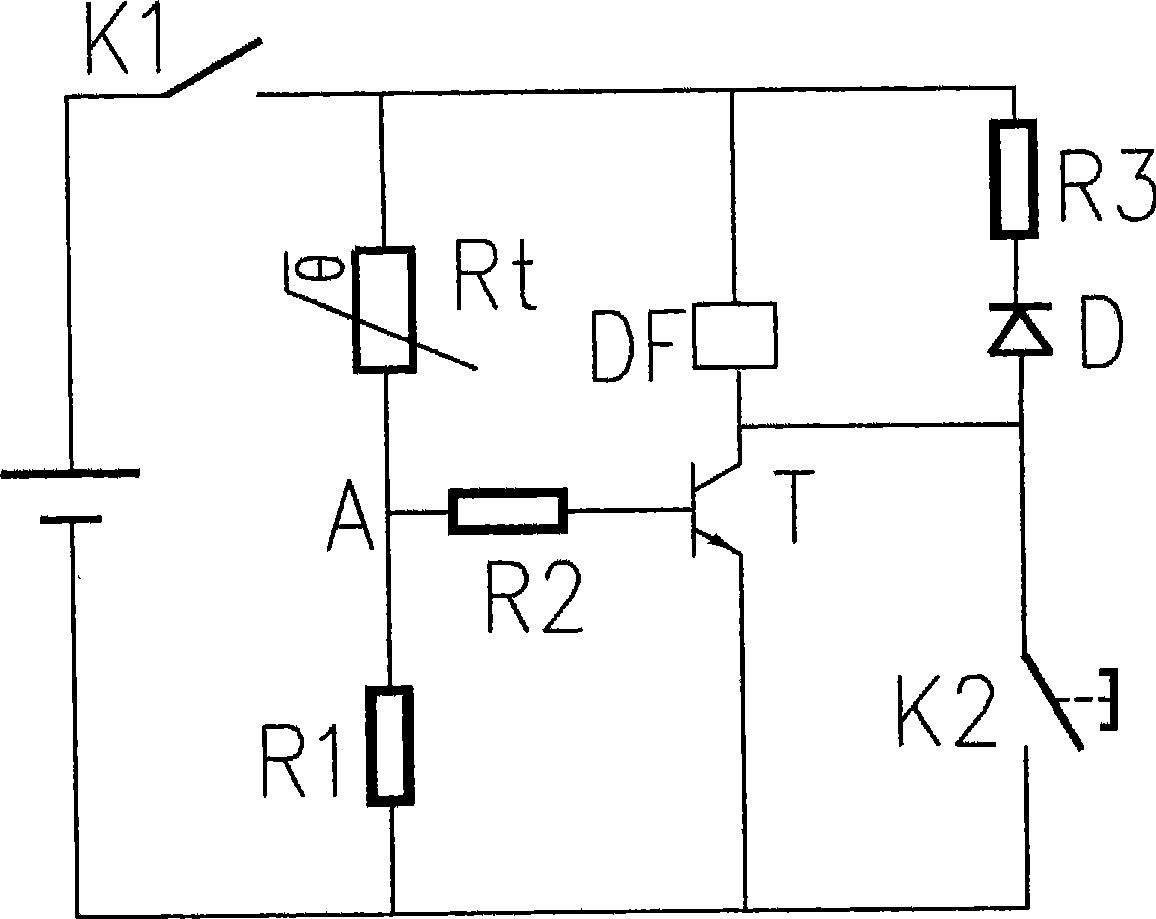

[0013] Depend on figure 2 It can be seen that the transistor T base of the amplifier circuit is connected to the resistance R 2 , resistor R 2 , resistance R 1 , The temperature sensor Rt is connected to point A; the resistance R 1 , emitter, manual button K and connected to the negative pole of the battery; the collector of the triode T is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com