Device and method for continuous refining waste purple impure copper

A technology of purple miscellaneous copper and equipment, which is applied in the field of equipment for continuous refining of waste miscellaneous copper, can solve the problems of unstable product quality, complicated flue gas treatment, unavoidable pollution, etc. The effect of venting smoke and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

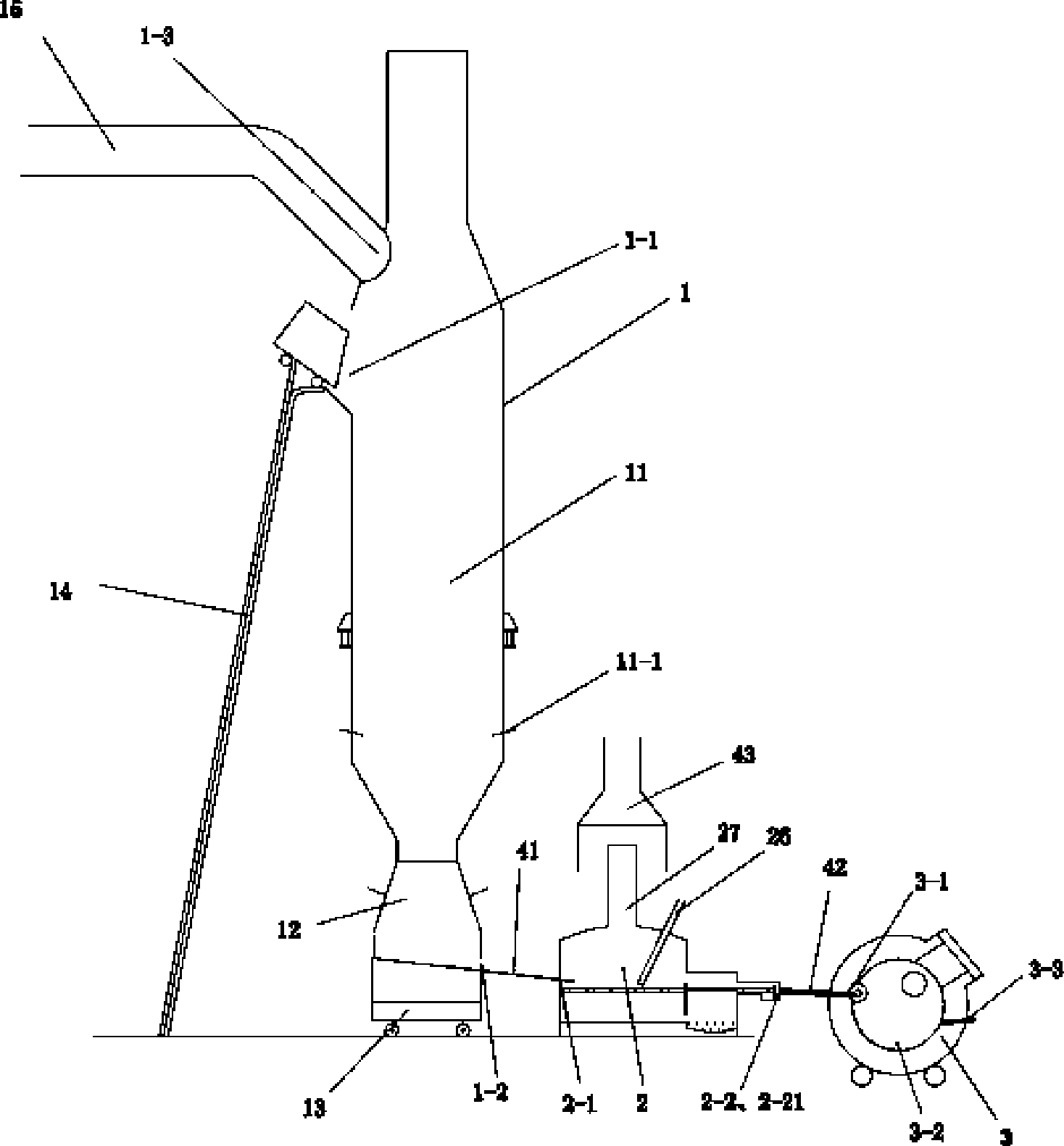

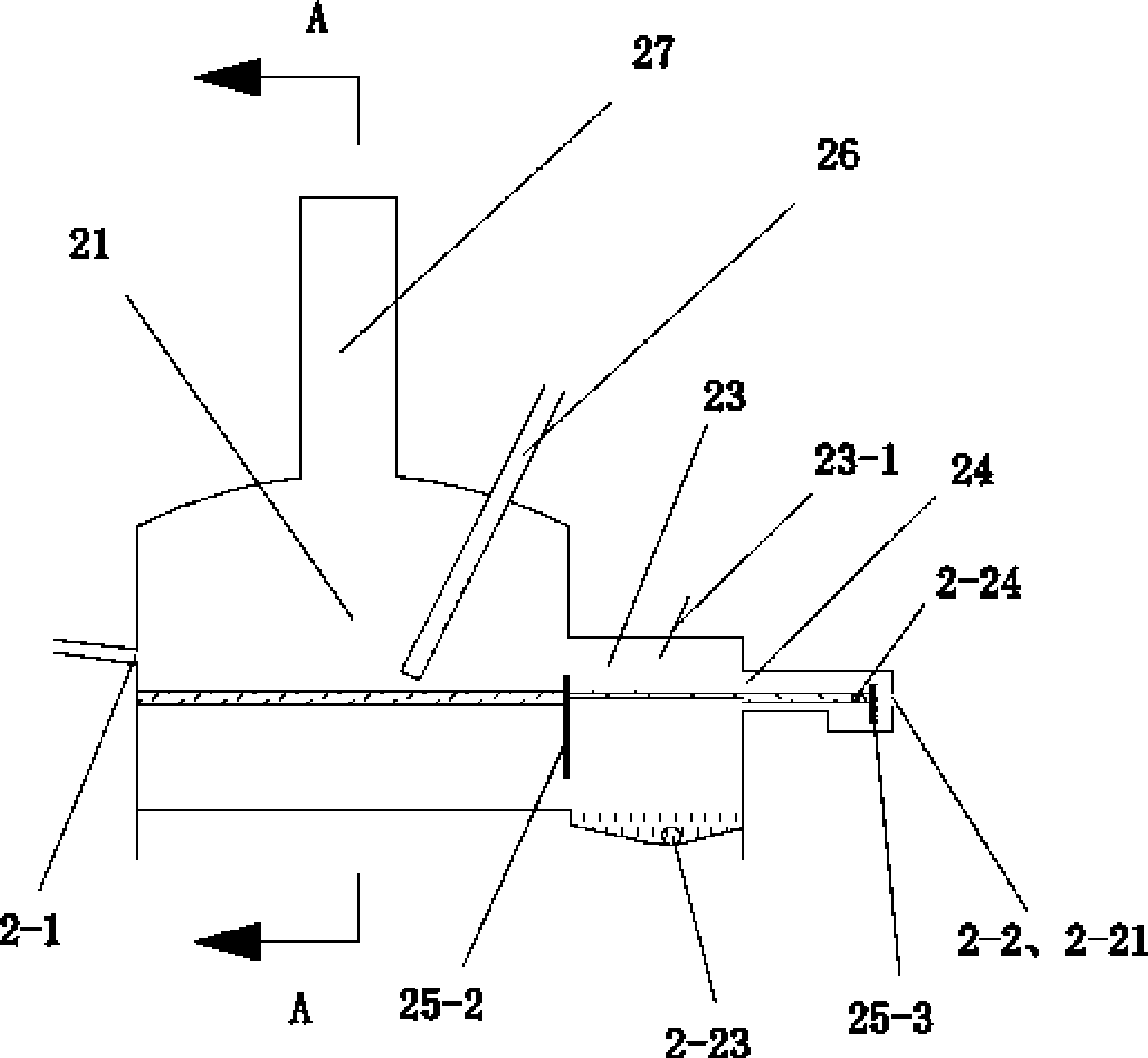

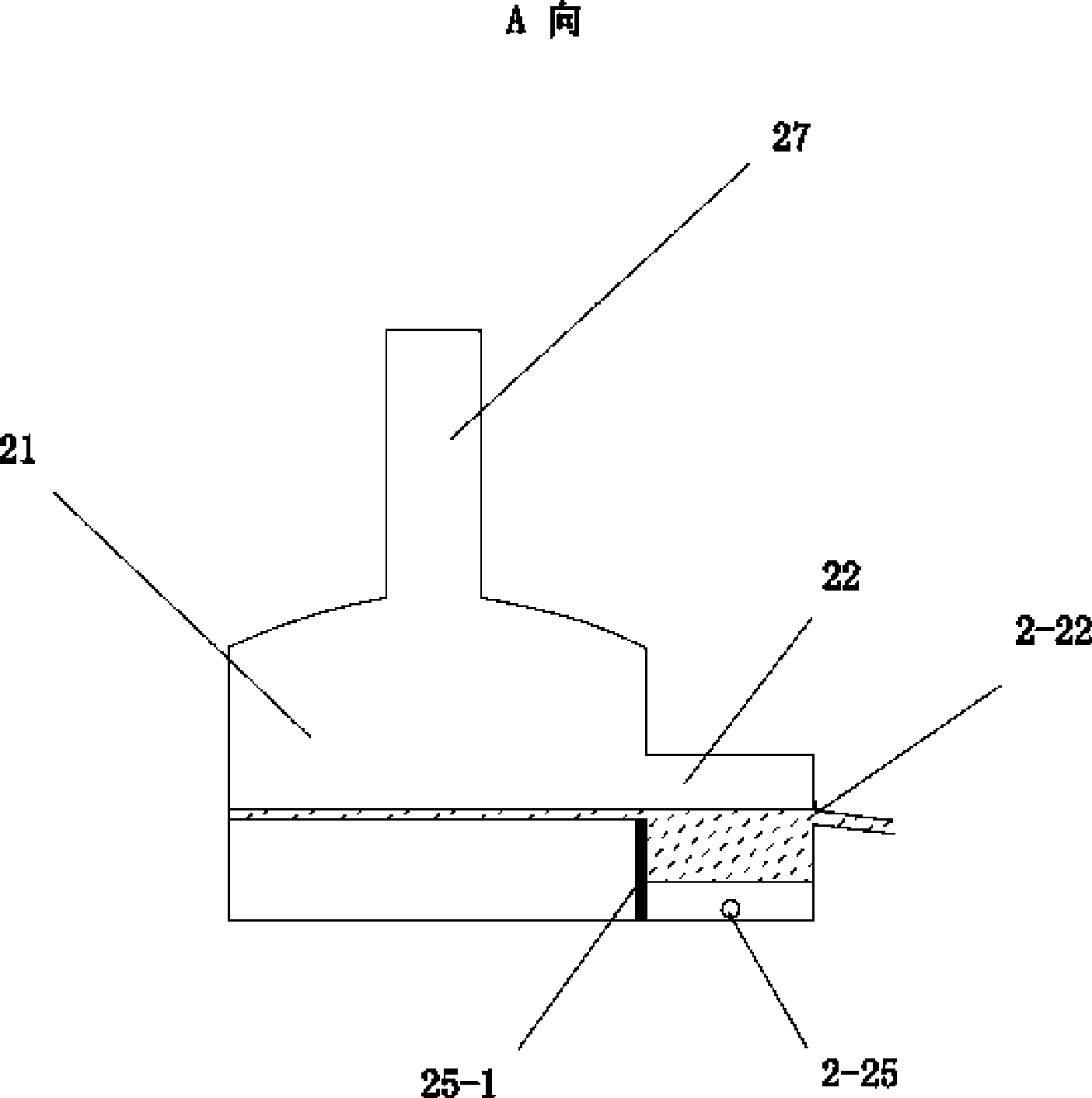

[0024] See Figure 1 to Figure 4 , The equipment for continuous refining of copper waste in the present invention includes a pre-oxidation shaft furnace 1, an oxidation furnace 2 and a reduction furnace 3.

[0025] The pre-oxidation shaft furnace 1 has a feed port 1-1, a liquid discharge port 1-2 and a smoke discharge port 1-3. The oxidation furnace 2 has a liquid inlet 2-1 and a discharge port 2-2, and the discharge port 2-2 includes a pure copper liquid discharge port 2-21, an acid slag discharge port 2-22, and a copper liquid slag discharge port containing heavy impurities 2-23, alkaline slag discharge port 2-24 and clarified copper liquid discharge port 2-25. The reduction furnace 3 has a liquid inlet 3-1 and a liquid discharge 3-2. A mixed copper liquid flow tank 41 is provided between the liquid outlet 1-2 of the pre-oxidation shaft furnace 1 and the liquid inlet 2-1 of the oxidation furnace 2 . A pure copper liquid flow tank 42 is provided between the pure copper liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com