Synchronous control system for ultraprecise double-layer macro/micromotion platform

A micro-movement platform and platform control technology, which is applied in the direction of control using feedback, can solve the problems of the system losing the deviation compensation ability, unable to feed back the active system, and exciting the resonance of the system, so as to simplify control, improve tracking accuracy, and prevent motion saturation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

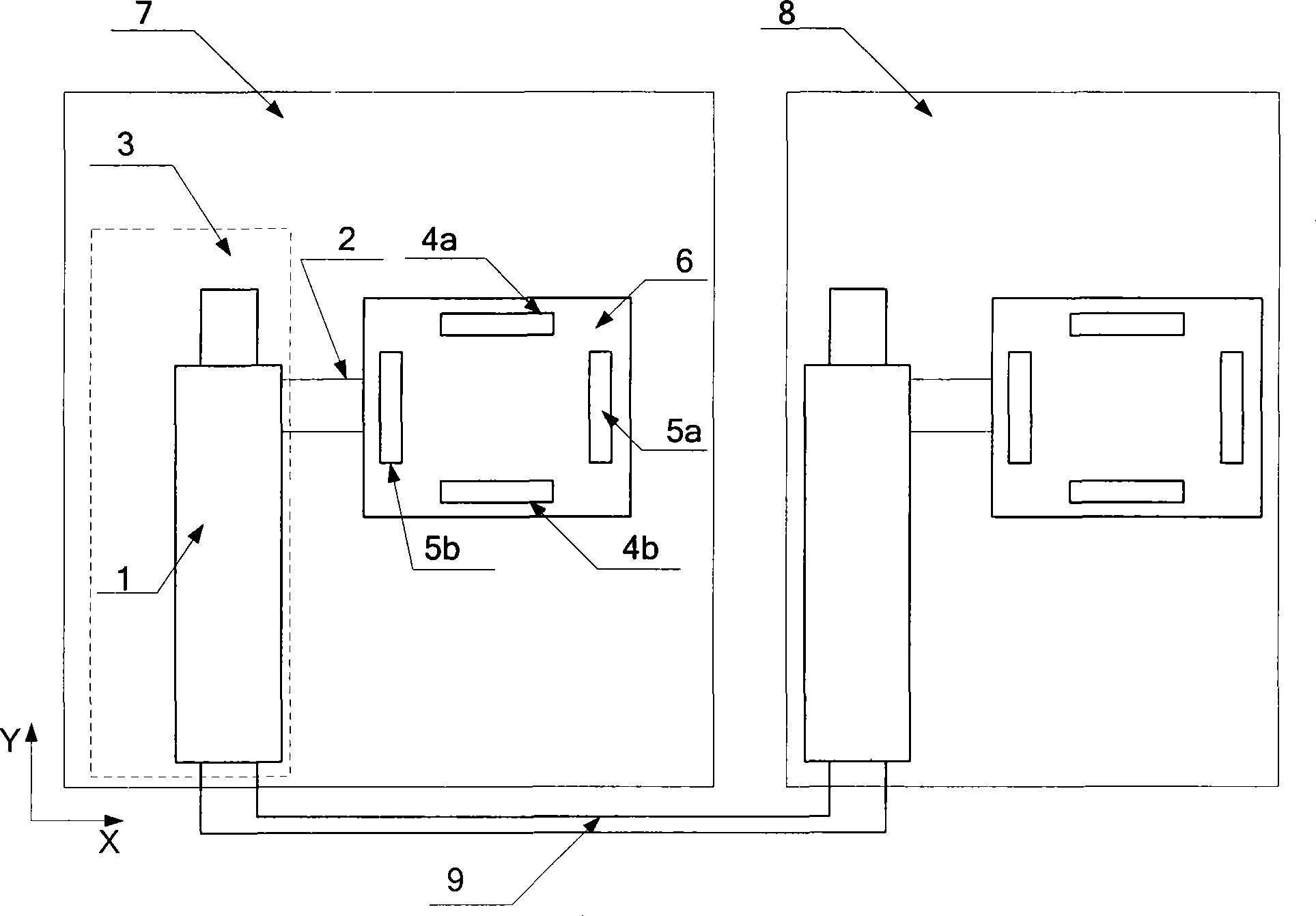

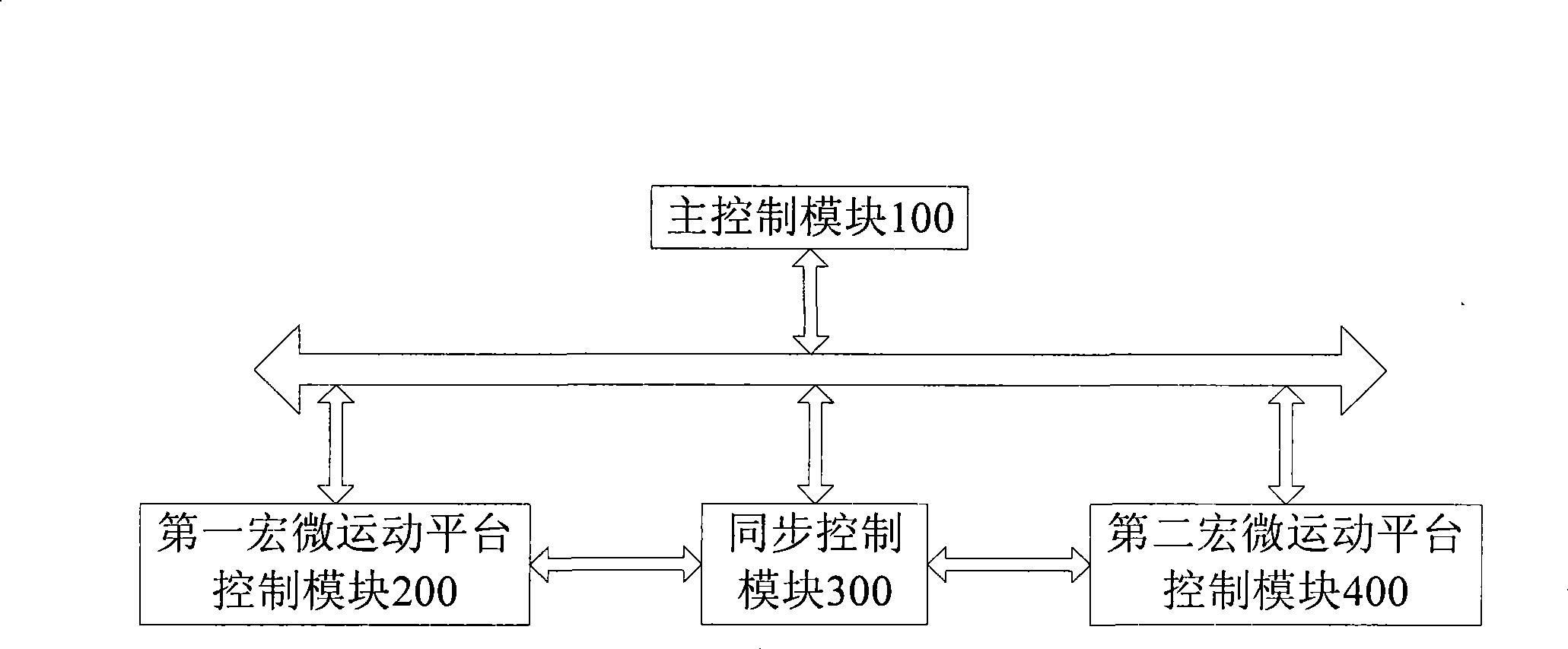

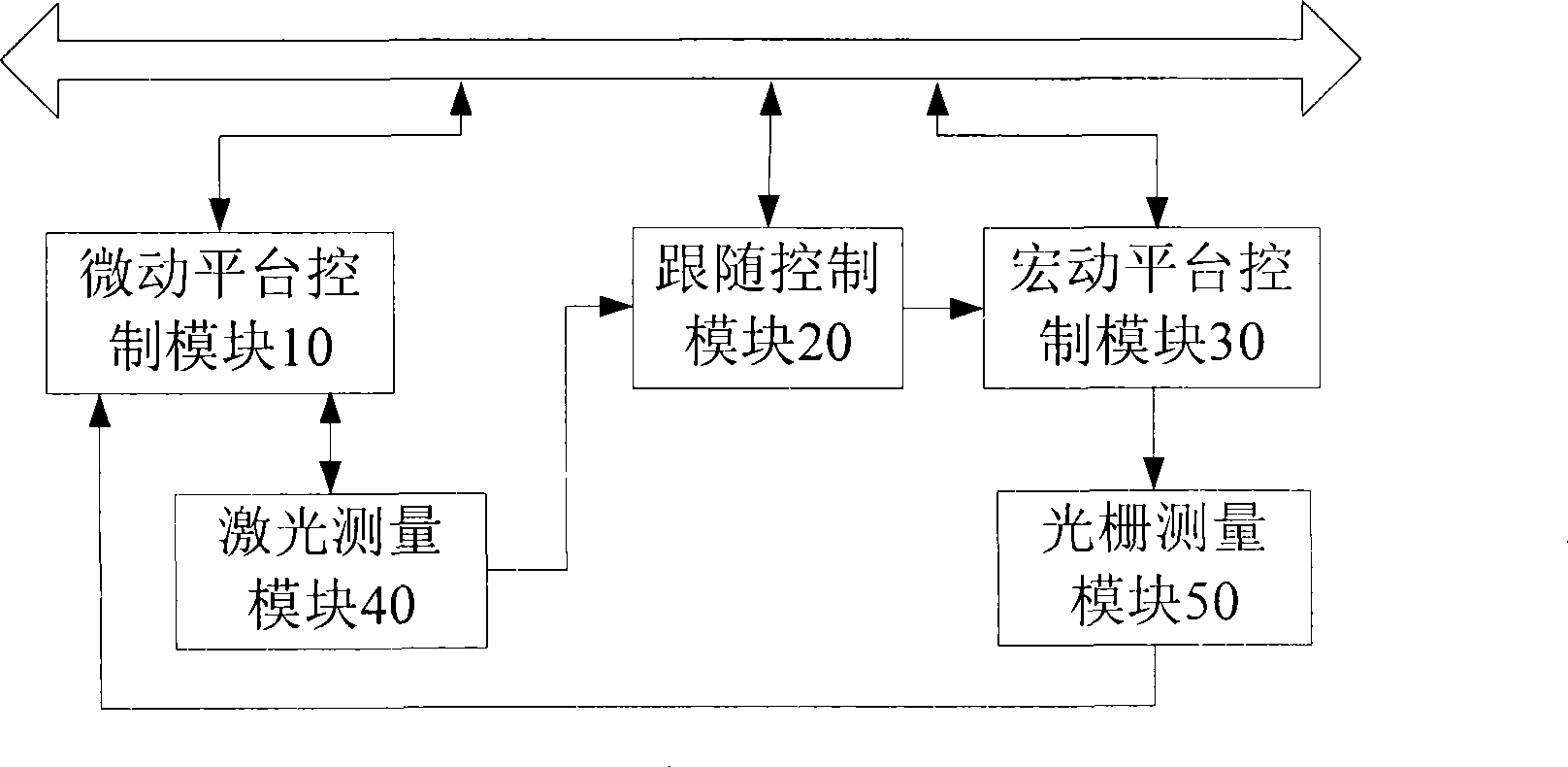

[0050] Such as Figure 4 As shown, the micro-motion platform control module 10 includes a micro-motion platform position converter 11, a micro-motion platform X to the first motor controller 12, a micro-motion platform X to the second motor controller 13, and a micro-motion platform Y to the first motor. The controller 14 and the micro-motion platform Y are directed to the second motor controller 15 .

[0051] The macro-motion platform control module 30 includes a macro-motion platform controller 31 and a force action converter 32 .

[0052] Such as Figure 4 As shown, the main control module 100 sends out a displacement command Yref, and the micro-motion platform position converter 11 receives the displacement command, and performs position conversion calculation on the difference between the displacement command and the actual position of the micro-motion platform, and obtains the respective target values of the four motors of the micro-motion platform The position signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com