Method for removing interconnecting metal layer surface oxidation membrane

A technology for interconnecting metals and surface oxidation, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve problems such as long time, rough surface morphology, and damage to the surface of the interconnected metal layer to avoid damage and reduce Effects of lattice changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

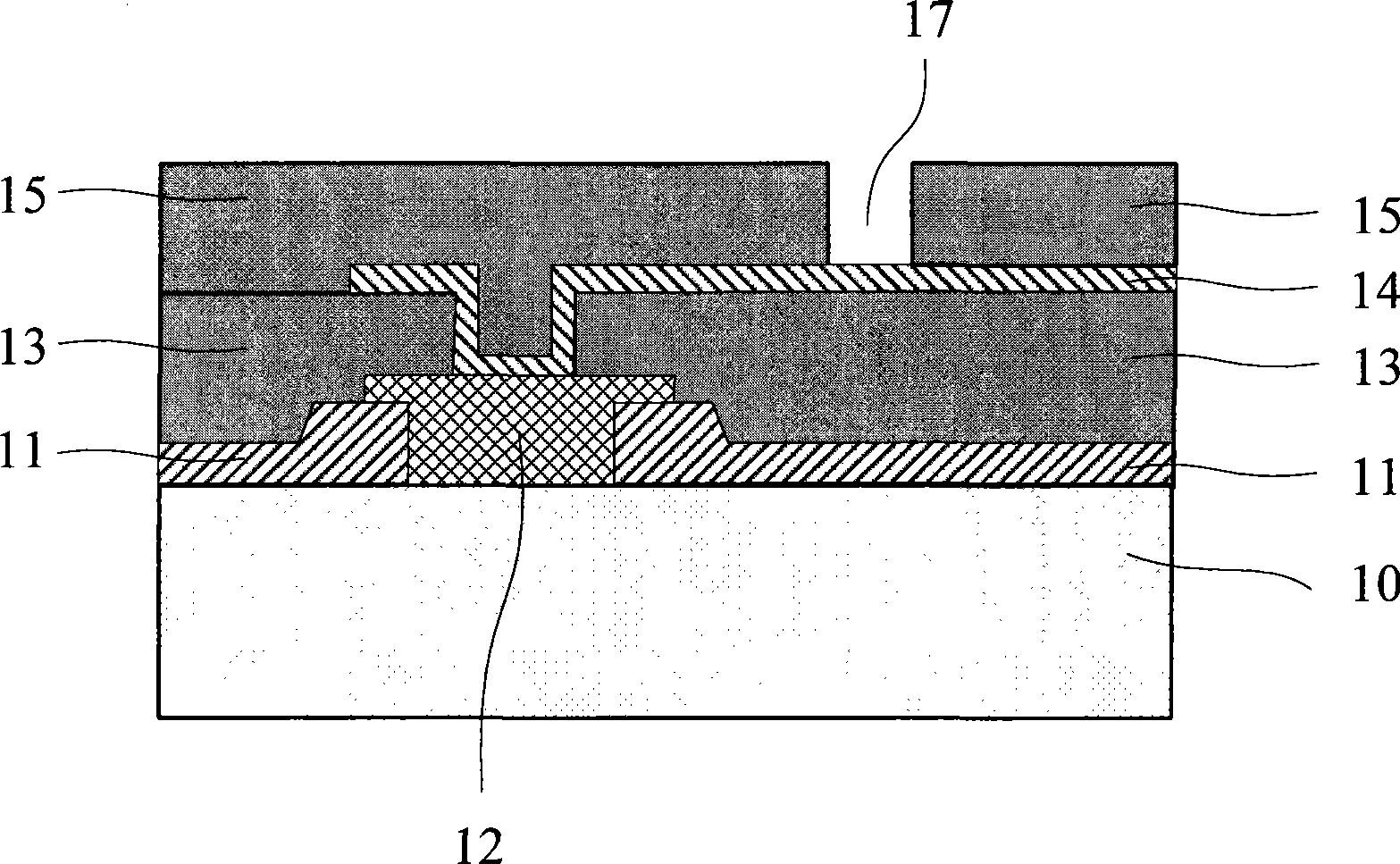

[0031] as attached figure 1 In the structure of the redistributed bumps shown, the material of the interconnected metal layer is metal aluminum. Since metal aluminum is extremely easy to oxidize in the air, an oxide film is formed. Therefore, as an example, ensure that the interconnected metal layer and the formed on The good electrical connection relationship of the redistributed metal layer needs to remove the oxide film layer on the surface of the interconnected metal layer. At present, the commonly used method for removing the oxide film layer is to use plasma sputtering, through non-oxidative plasma sputtering The surface of the interconnected metal layer is irradiated to achieve the purpose of removing the oxide film on the surface of the interconnected metal layer.

[0032] However, the time of plasma sputtering depends on the thickness of the oxide film on the surface of the interconnected metal layer. If the thickness of the oxide film is larger, the time of plasma sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com