Method for sealing and wrapping edge using fluoro-resin seamless film

A fluororesin and fluororesin coating technology, which is applied in the direction of stove/stove bracket/shelf, special materials for cooking utensils, etc. The effect of reduced manufacturing cost, uniform force on edging, and reduced material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Reference Figure 1 to Figure 5 As shown, the fluororesin seamless film sealing method in this embodiment includes the following steps:

[0038] ①Put the fluororesin raw material into the mold. The fluororesin raw material is added with a color agent with a mass percentage of 1-5%. The color agent is high temperature resistant and has the same color as the fluororesin coating base cloth. It can be obtained by one of the following methods: Cylinder 1, see figure 1 Shown:

[0039] The first one is to hold the pressure, demould, and finally sinter the molded casting. The nominal pressure of the hold is 200-300kg / cm 2 ;

[0040] The second type is mechanical injection;

[0041] The third type is mechanical vulcanization;

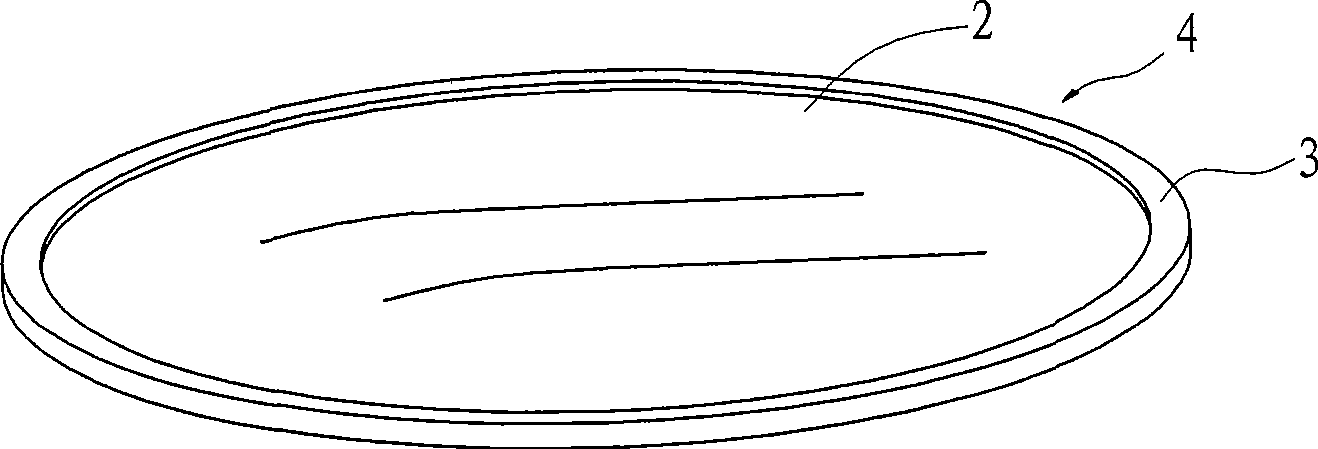

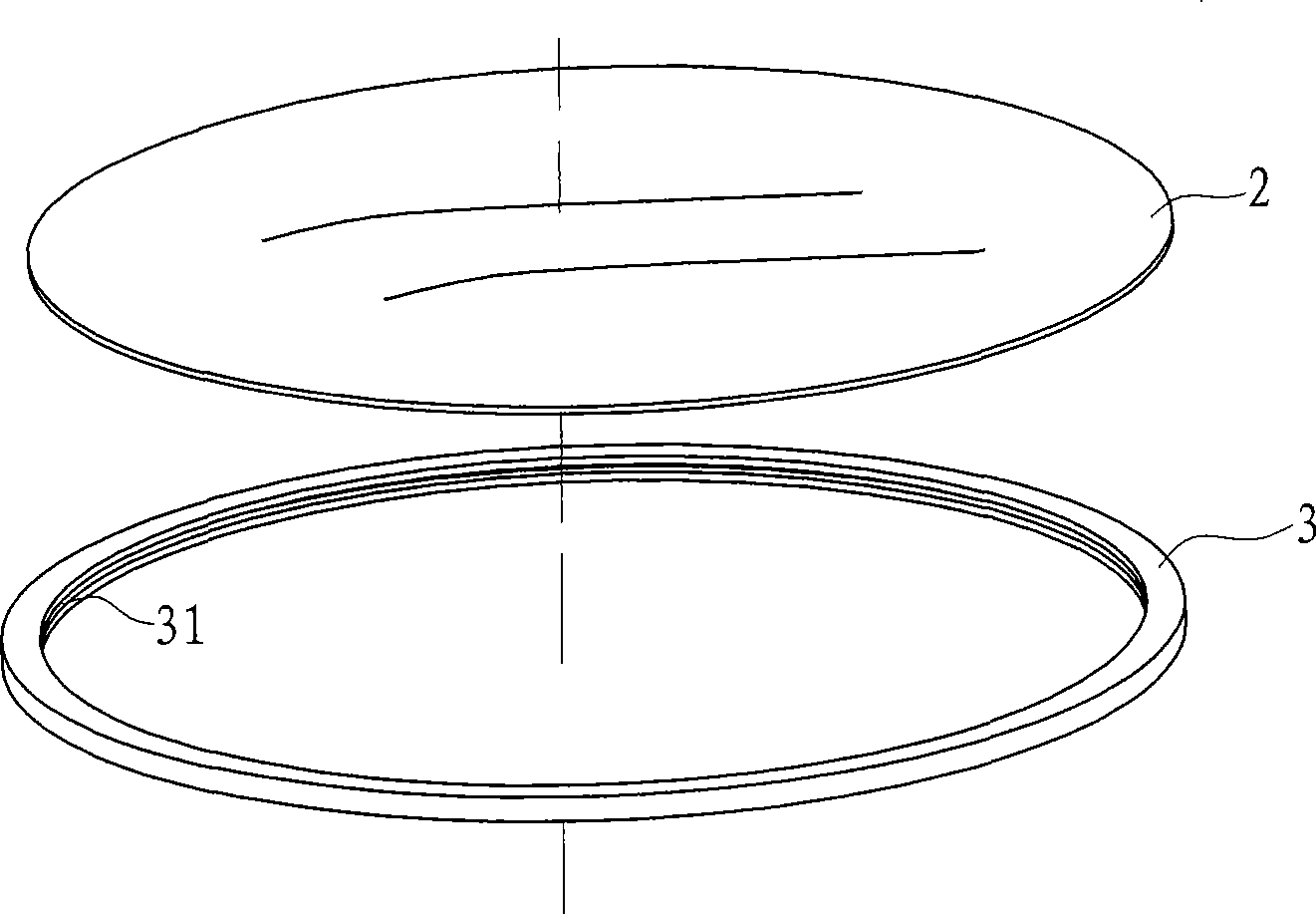

[0042] ② Cut the obtained cylindrical body 1 into a ring 3, the axial thickness of the ring 3 after cutting is 0.1-0.3 mm, and cut an annular gap 31 on the inner wall of the ring 3, see image 3 shown;

[0043] ③Cut the fluororesin coate...

Embodiment 2

[0047] Example 2: Reference Image 6 , Figure 7 with Figure 8 , the fluororesin seamless film edge sealing method in the present embodiment comprises the following steps:

[0048] ①Put the fluororesin raw material into the mold. The fluororesin raw material is added with a color agent with a mass percentage of 1-5%. The color agent is high temperature resistant and has the same color as the fluororesin coating base cloth 2. Get barrel 1:

[0049] The first one is to hold the pressure, demould, and finally sinter the molded casting. The nominal pressure of the hold is 200-300kg / cm 2 ;

[0050] The second type is mechanical injection;

[0051] The third type is mechanical vulcanization;

[0052] ② Cut the obtained cylindrical body 1 into a ring 3, the axial thickness of the ring 3 after cutting is 0.1-0.3 mm, see Image 6 shown;

[0053] ③Cut the fluororesin-coated base cloth 2 into a shape suitable for the ring 3, and then place the cut fluororesin-coated base cloth 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com