Double-layer polyamide surface layer composite reverse osmosis membrane and preparation method thereof

A double-layer polyamide and reverse osmosis membrane technology, which is applied in the field of water treatment, can solve problems such as short service life, loss of desalination performance, and influence on the wide application of reverse osmosis membranes, and achieve high salt retention rate, prolong service life, increase The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

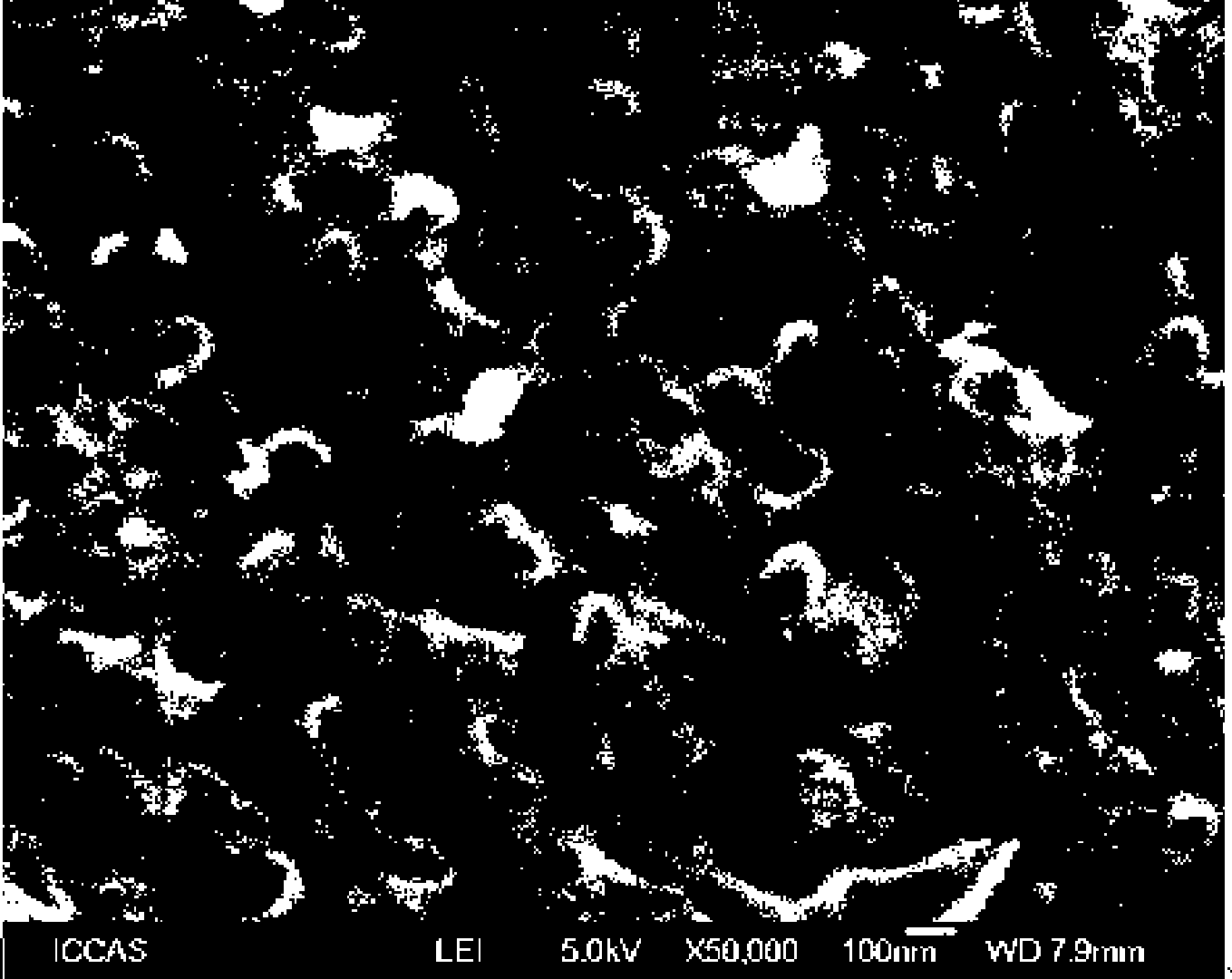

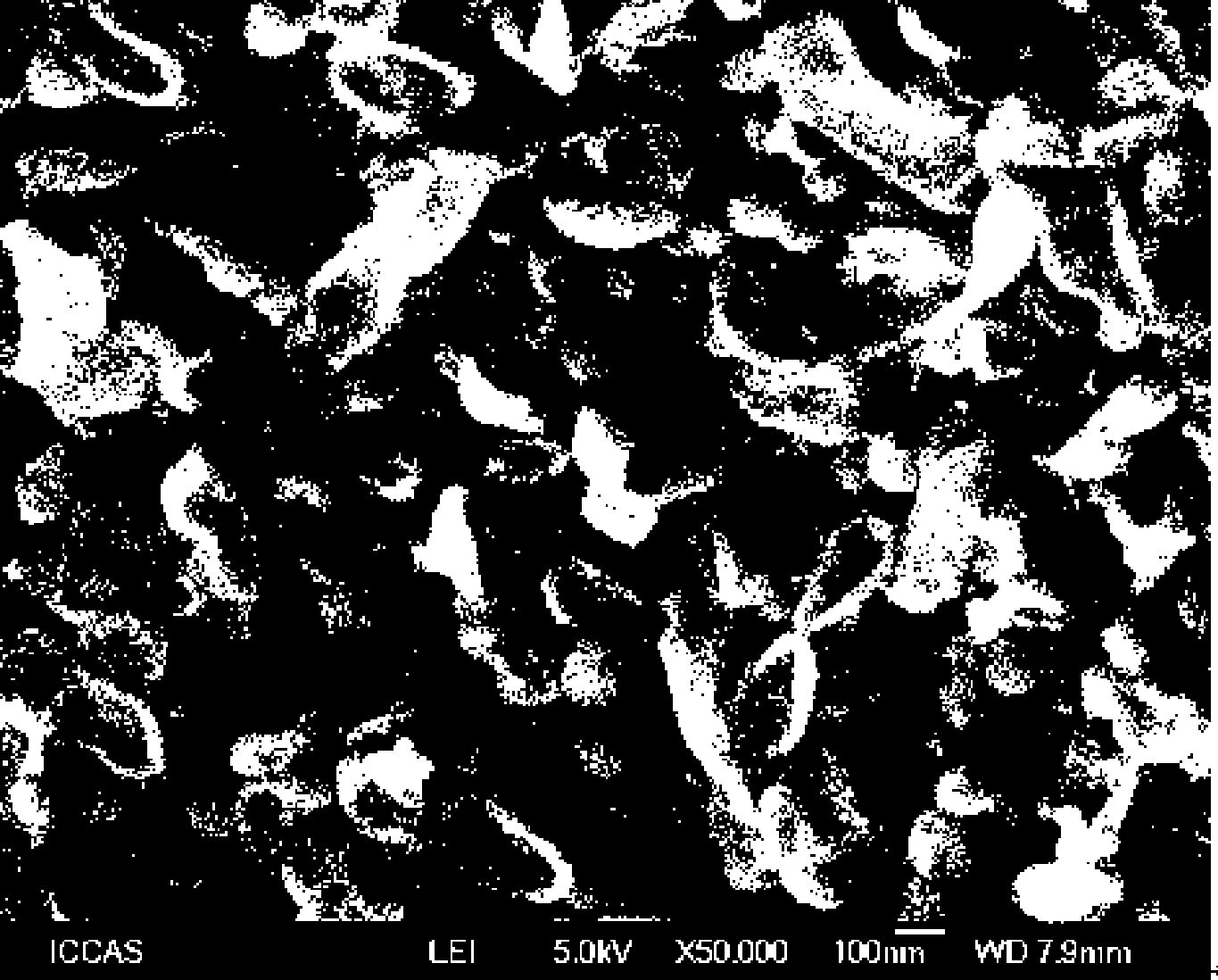

Image

Examples

Embodiment 1

[0021] Embodiment 1: prepare composite reverse osmosis membrane according to the following steps:

[0022] (1) Preparation of A solution: get m-phenylenediamine 21.9g and dissolve it in 657g water to prepare an aqueous solution whose weight concentration is 3%. 7.3g of pyrrolidone, 14.6g of 2% triethylamine and 29.2g of 4% camphorsulfonic acid were stirred and dissolved to obtain A solution.

[0023] (2) Preparation of solution B: 0.9 g of trimesoyl chloride was dissolved in 597 g of cyclohexane to prepare an organic solution with a weight concentration of 0.15%, and solution B was obtained after stirring and dissolving.

[0024] (3) The preparation of C solution: with the preparation of A solution: get m-phenylenediamine 21.9g and be dissolved in 657g water and be mixed with the aqueous solution that weight concentration is 3%, after it dissolves completely, add weight percentage in this aqueous solution again 7.3g of 1% N-methylpyrrolidone, 14.6g of 2% triethylamine and 29....

Embodiment 2

[0027] Embodiment 2: prepare composite reverse osmosis membrane according to the following steps:

[0028] (1) Preparation of A solution: same as Example 1.

[0029] (2) Preparation of B solution: same as in Example 1.

[0030] (3) Preparation of C solution: same as in Example 1.

[0031] (4) Contact the porous support layer with solution A for 20 seconds, remove excess solution with a rubber roller, and form a polysulfone support layer on the porous support layer; then contact this polysulfone support layer with solution B for 10 seconds to form the first After the organic solvent evaporates to dryness, contact with solution C for 10 seconds to form a second polyamide surface layer, and then put it in an oven at 60°C to dry for five minutes to obtain a double-layer polyamide surface layer composite reverse osmosis membrane.

[0032] Take the diaphragm and test it on the diaphragm monitoring platform under the test conditions of 2000ppm NaCl aqueous solution, 225psi operatin...

Embodiment 3

[0033] Embodiment 3: prepare composite reverse osmosis membrane according to the following steps:

[0034] (1) Preparation of A solution: same as Example 1.

[0035] (2) Preparation of B solution: same as in Example 1.

[0036] (3) Preparation of C solution: same as in Example 1.

[0037] (4) Contact the porous support layer with solution A for 20 seconds, remove excess solution with a rubber roller, and form a polysulfone support layer on the porous support layer; then contact this polysulfone support layer with solution B for 10 seconds to form the first After the organic solvent volatilizes, contact with solution C for 20 seconds to form a second polyamide surface layer, and then put it in an oven at 60°C to dry for five minutes to obtain a double-layer polyamide surface layer composite reverse osmosis membrane.

[0038] Take the diaphragm and test it on the diaphragm monitoring platform under the test conditions of 2000ppm NaCl aqueous solution, 225psi operating pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com