Sheet follow-up supporting device of bending machine

A supporting device and bending machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as noise, small workpiece splashing, damage to equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

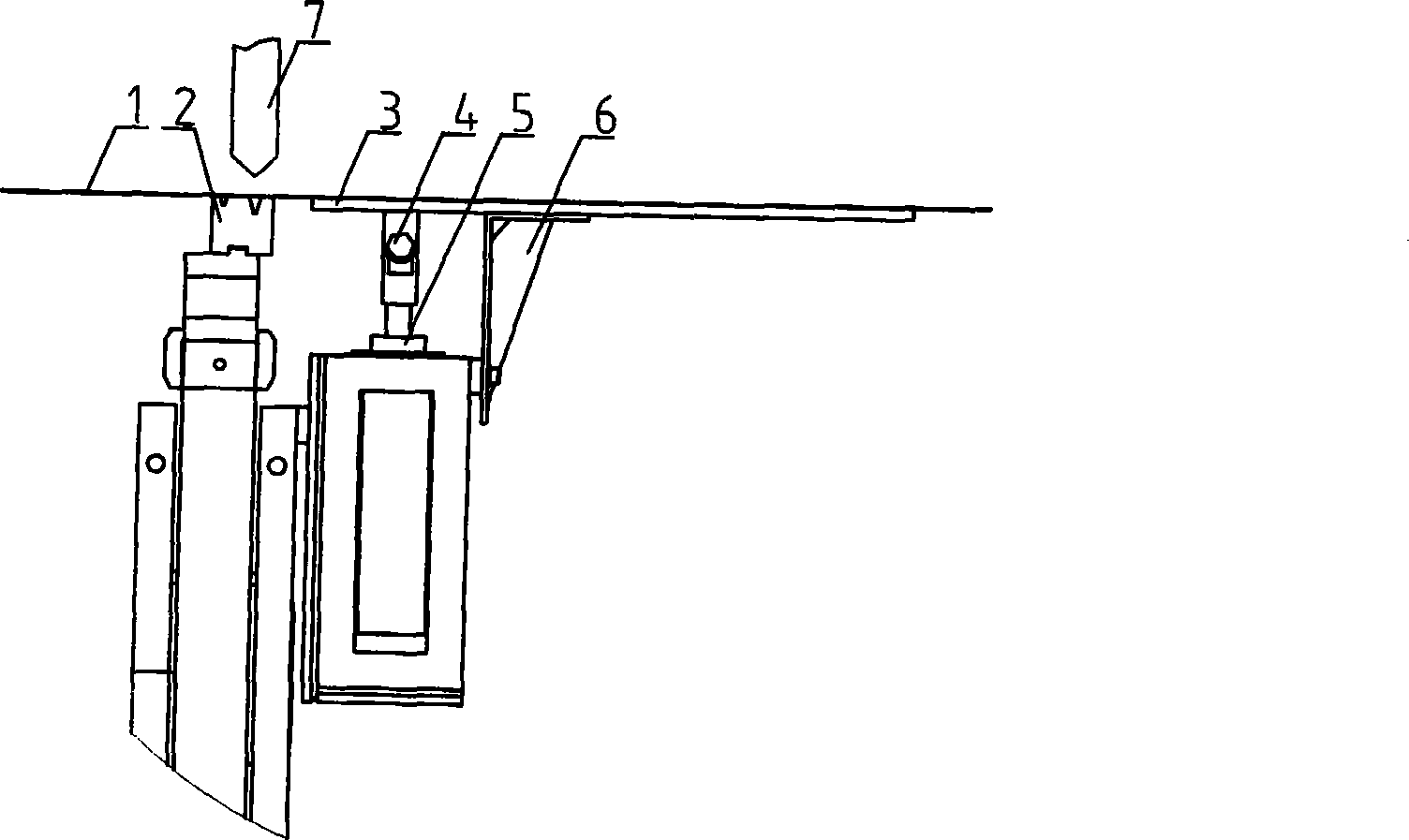

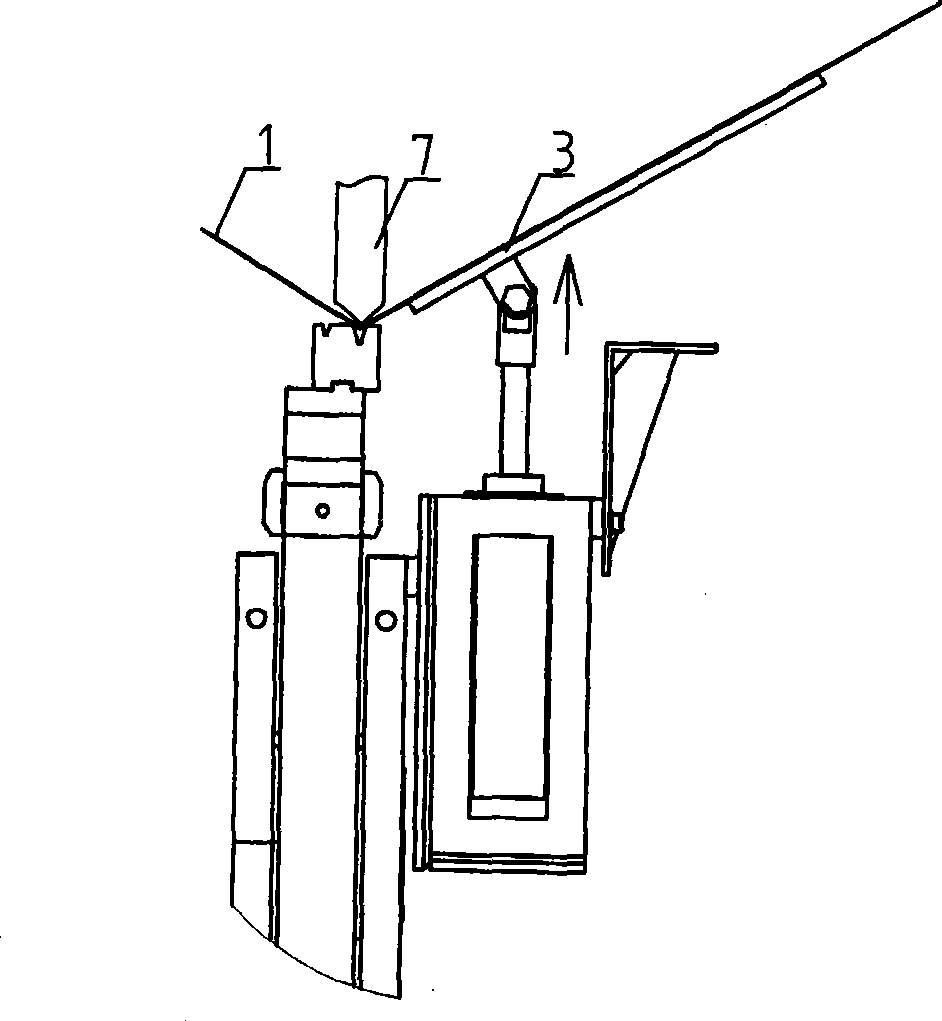

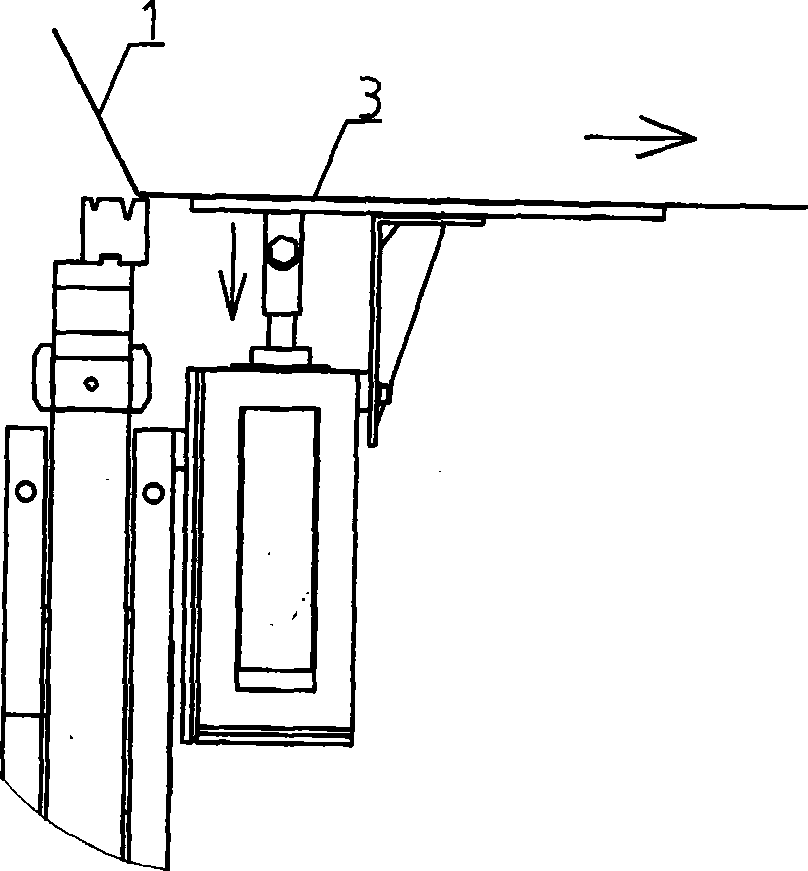

[0014] like figure 1 , the present invention is arranged at the place where the lower die 2 of the bending machine workbench faces the discharge port, and is connected with the control system of the bending machine, and is connected to the piston of the cylinder 5 by at least two cylinders 5 distributed on the lower side of the discharge port. The supporting plate 3 on the top of the rod is composed of an inductor, the cylinder 5 is fixedly connected to the lower part outside the discharge port of the bending machine workbench, the bottom surface of the supporting plate 3 is provided with a hinged seat, and the top of the piston rod of the cylinder 5 is connected to the bottom surface of the supporting plate 3 The hinged seats are connected by the hinged shaft 4. The action of the cylinder 5 is issued by the control system according to the timing of the bending action.

[0015] An auxiliary supporting device 6 for the sheet material 1 is also provided outside the cylinder 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com