Film isolation type oil storage and transportation apparatus

A technology for membrane isolation and oil products, which is applied in the equipment for storage and transportation of oil products under normal pressure, and in the field of low pressure, can solve the problems of environmental protection, safety, quality and other problems of breathing loss, achieve the effects of reducing sediment adhesion, avoiding direct breathing, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

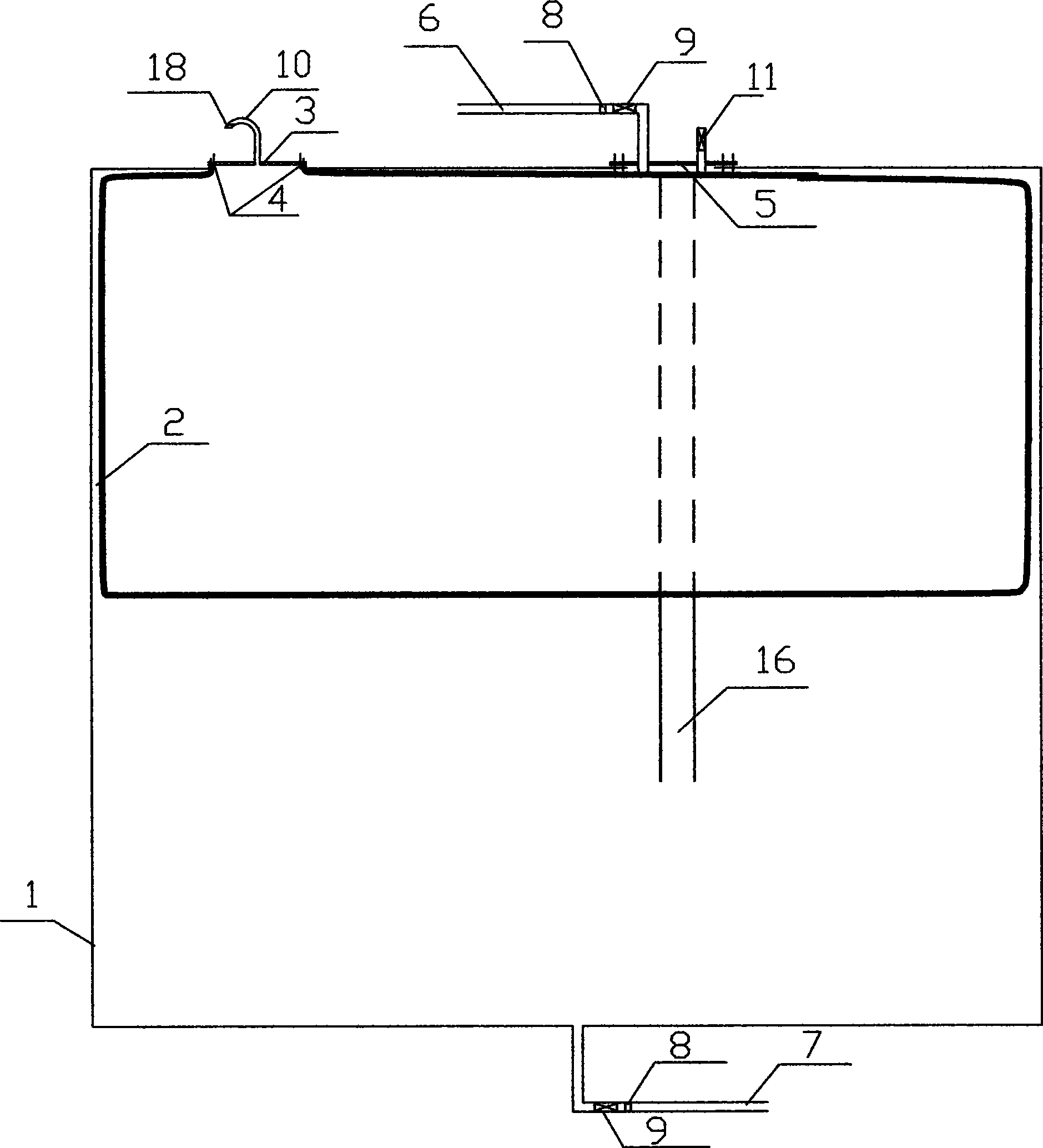

[0040] Implementation Mode 1: Transformation of Vertical Oil Storage Tank

[0041] Such as figure 2 , including a housing 1, an oil inlet pipe 6, an oil outlet pipe 7 and a breathing port 10; the housing 1 is provided with a membrane 2 larger than its volume, and the upper part of the membrane 2 is fixed at the membrane fixing section 4 around the upper edge of the housing 1, The rest of the membrane 2 is separated from the housing 1, the inner layer of the membrane 2 communicates with the breathing port 10, and the membrane 2 isolates the inner cavity of the housing 1 from the air; the oil inlet pipe 6 and the oil outlet pipe 7 are arranged at the bottom of the housing 1 , communicated with the inner cavity of the housing 1; the oil inlet pipe 6 and the oil outlet pipe 7 are provided with a valve 9 and a quick connector 8, and the top of the housing 1 is provided with a safety valve 11;

[0042] The effect of safety valve 11 is consistent with the exhalation effect of the b...

Embodiment approach 2

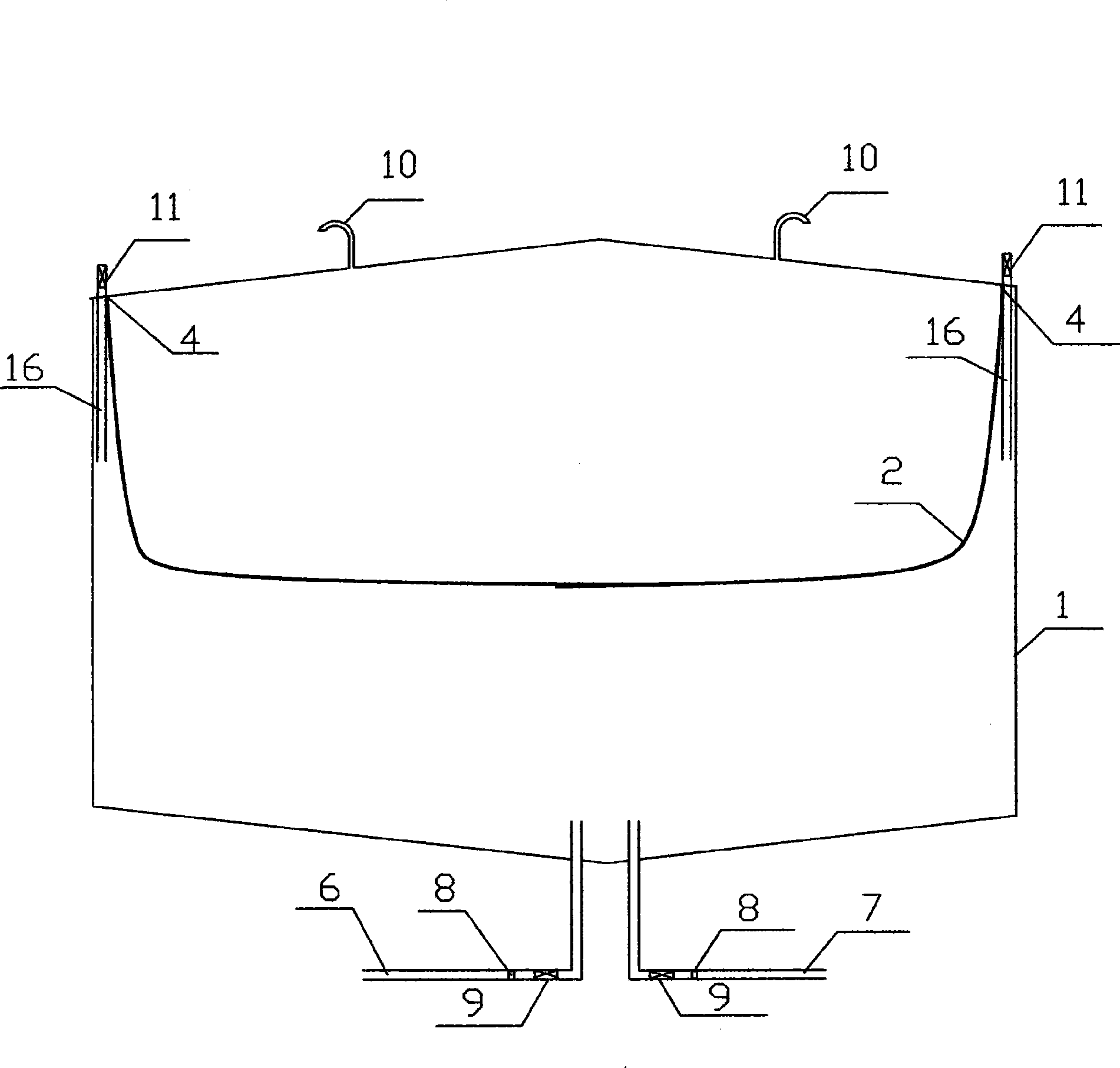

[0047] Implementation Mode 2: Horizontal Oil Storage Tank

[0048] Such as image 3 , 4, including housing 1, oil inlet pipe 6, oil outlet pipe 7 and breathing port 10, housing 1 is provided with a membrane 2 larger than its volume, and the top of membrane 2 is fixed on the membrane fixing section around the upper membrane installation port 3 of housing 1 4, the rest of the membrane 2 is separated from the casing 1, the inner layer of the membrane 2 communicates with the breathing port 10, and the membrane 2 isolates the inner cavity of the casing 1 from the air; the oil inlet pipe 6 is arranged on the top of the casing 1, and the outlet The oil pipe 7 is arranged at the bottom of the housing 1 and communicates with the inner cavity of the housing 1 . The oil inlet pipe 6 and the oil outlet pipe 7 are both provided with a valve 9 and a quick connector 8 . The oil inlet 6 and the oil outlet 7 can also be combined and located at the bottom.

[0049] The breathing port 10 is p...

Embodiment approach 3

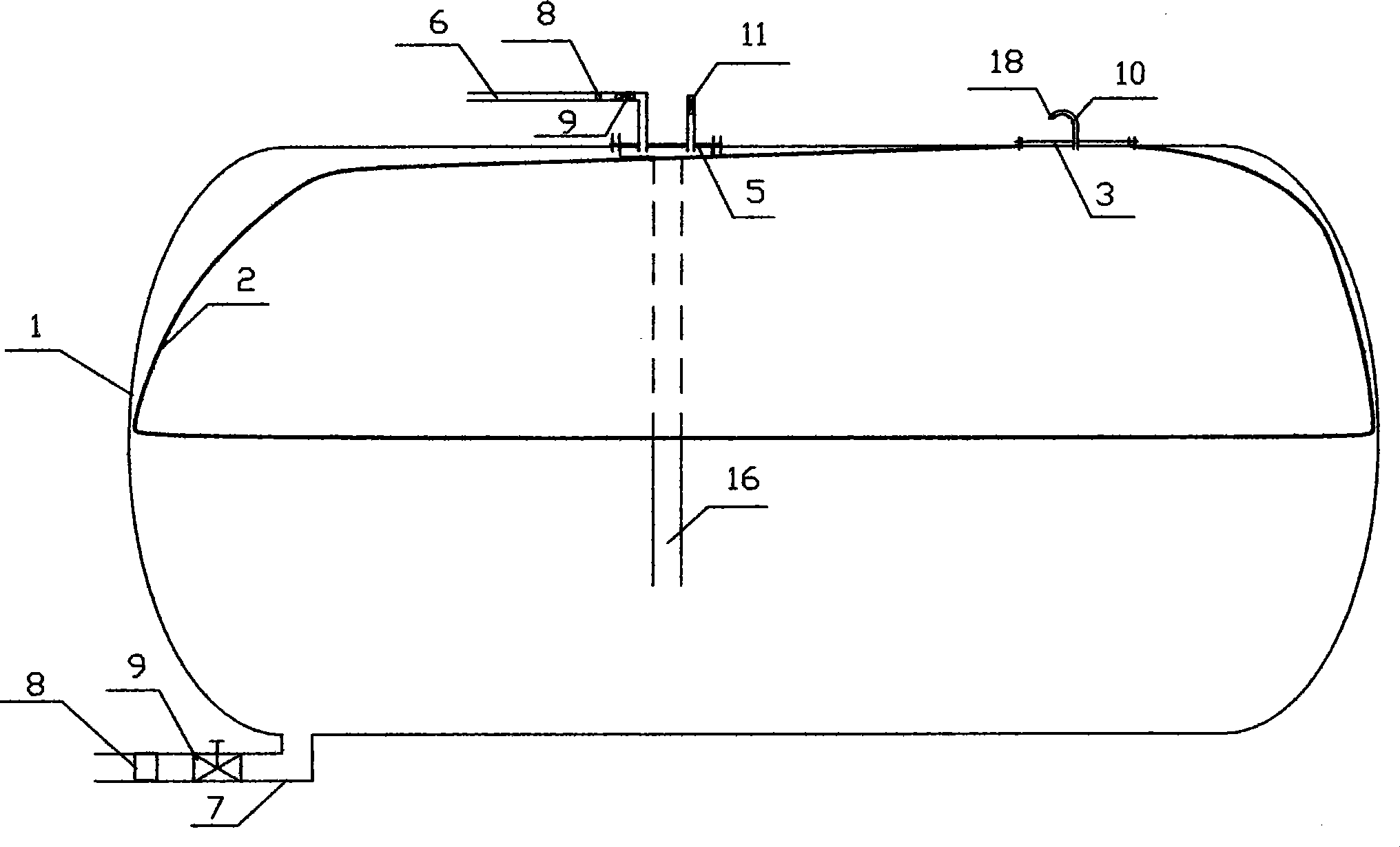

[0052] Implementation Mode 3: Transformation of the equipment oil tank with one end of the float on the oil pump assembly

[0053] Such as Figure 5 , 6 , including housing 1, oil inlet pipe 6, oil outlet pipe 7 and breathing port 10; housing 1 is provided with a membrane 2 larger than its volume, and the upper part of membrane 2 is fixed in two layers around the installation port 13 of the upper oil pump assembly of housing 1 There are 4 fixed sections of the film, the rest of the film 2 is separated from the housing 1, the inner layer of the film 2 communicates with the breathing port 10, and the film 2 isolates the inner cavity of the housing 1 from the air; the oil inlet pipe 6 and the oil outlet pipe 7 are set The top of the housing 1 communicates with the inner chamber of the housing 1 .

[0054] An oil pump assembly 12 is arranged between the housing 1 and the membrane 2, the oil pump assembly 12 is installed below the installation port 13 of the oil pump assembly, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com