Hydrogenation of diene-based polymer latex

A technology of polymers and dienes, applied in the field of selective hydrogenation of carbon-carbon double bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0112] The following examples illustrate the scope of the invention and are not intended to limit it.

[0113] The results clearly show the various operating conditions under which it is possible to obtain high degrees of hydrogenation.

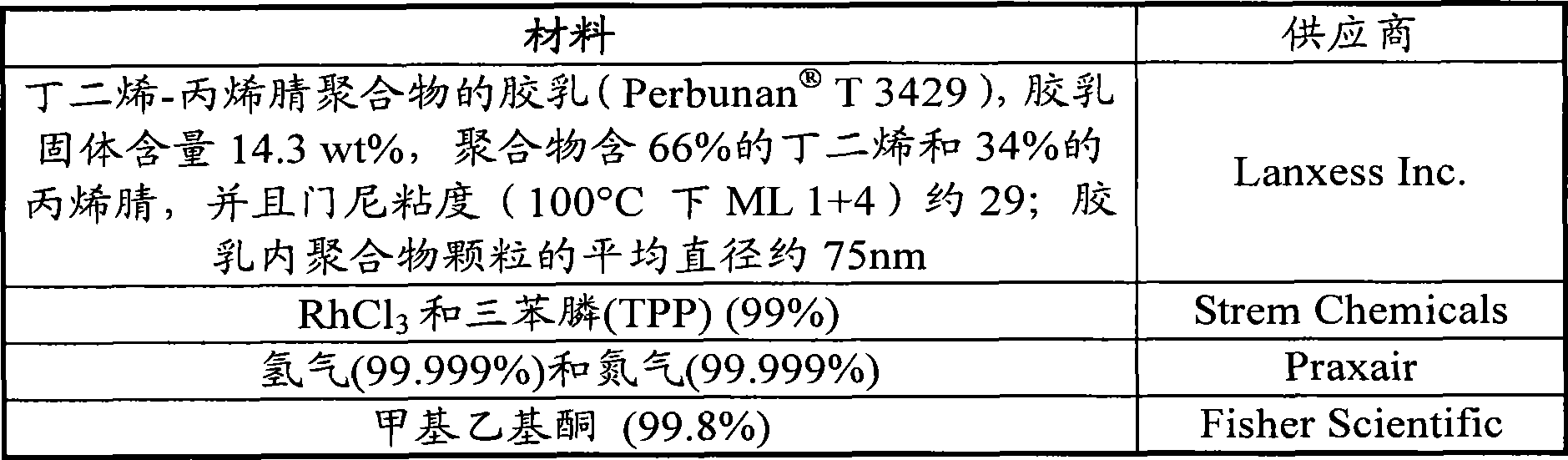

[0114] The materials used in the hydrogenation reactions are listed in Table 1.

[0115] Table 1: Specifications of materials

[0116]

example 1

[0118] (for comparison, only rhodium salt (representing the first major catalyst component) is used without the secondary water-insoluble catalyst component)

[0119] A 300 ml glass-lined stainless steel autoclave with temperature control, stirrer and hydrogen addition point was used as the reactor.

[0120] Mix 25ml of the above latex, 75ml of water, and 0.012g of RhCl 3 ·3H 2 O was added to the reactor. The latex was then degassed with nitrogen. The temperature was raised to 100°C and hydrogen was introduced to 1000 psi (6.8 MPa).

[0121] After 4 hours, the degree of hydrogenation reached 23%. A gel was produced and the resulting polymer was partially insoluble in methyl ethyl ketone.

example 2

[0122] Example 2: (the present invention)

[0123] The same procedure as described in Example 1 was used. However 0.013g of RhCl was used 3 ·3H 2 O and 0.36 g of PPh 3 , the hydrogen pressure used was 1000 psi (6,8 MPa) and the temperature was 160°C.

[0124] After 19 hours, a degree of hydrogenation of 97% was achieved. The resulting latex can coagulate and the final rubber is gel-free and all soluble in methyl ethyl ketone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com