Gas ironing method for broad width fabric and gas type large-sized ironing unit

An ironing machine and large-format technology, applied in ironing machines, applications, household appliances, etc., can solve the problems of slow heat dissipation of steam, fatigue work of operators, and restrictions on working conditions of operators, so as to achieve unlimited working hours , Improved operational flexibility, and improved operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

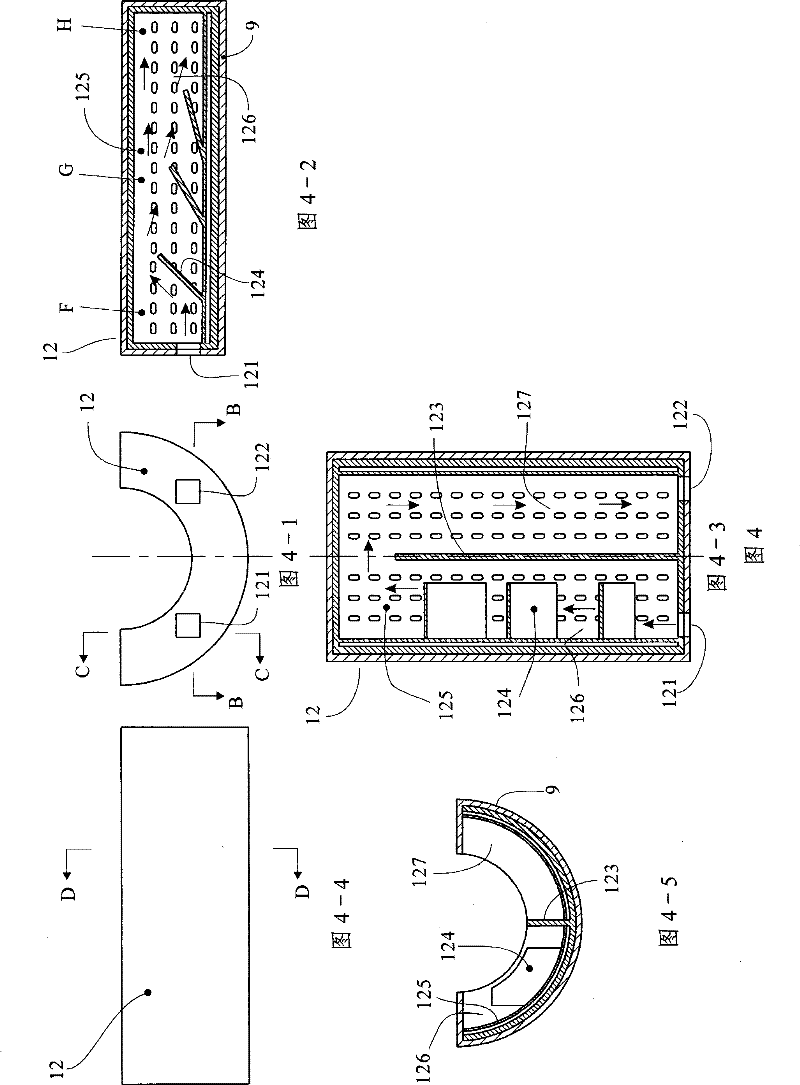

[0055] The main features of the method for ironing large-format fabrics with gas and the gas-fired large-scale ironing unit equipment of the present invention are that the hot air heated by the gas burner is used as the heat source for heating the bottom of the pan, and the structure of the bottom of the heating pan is correspondingly improved to improve Thermal efficiency of gas burners.

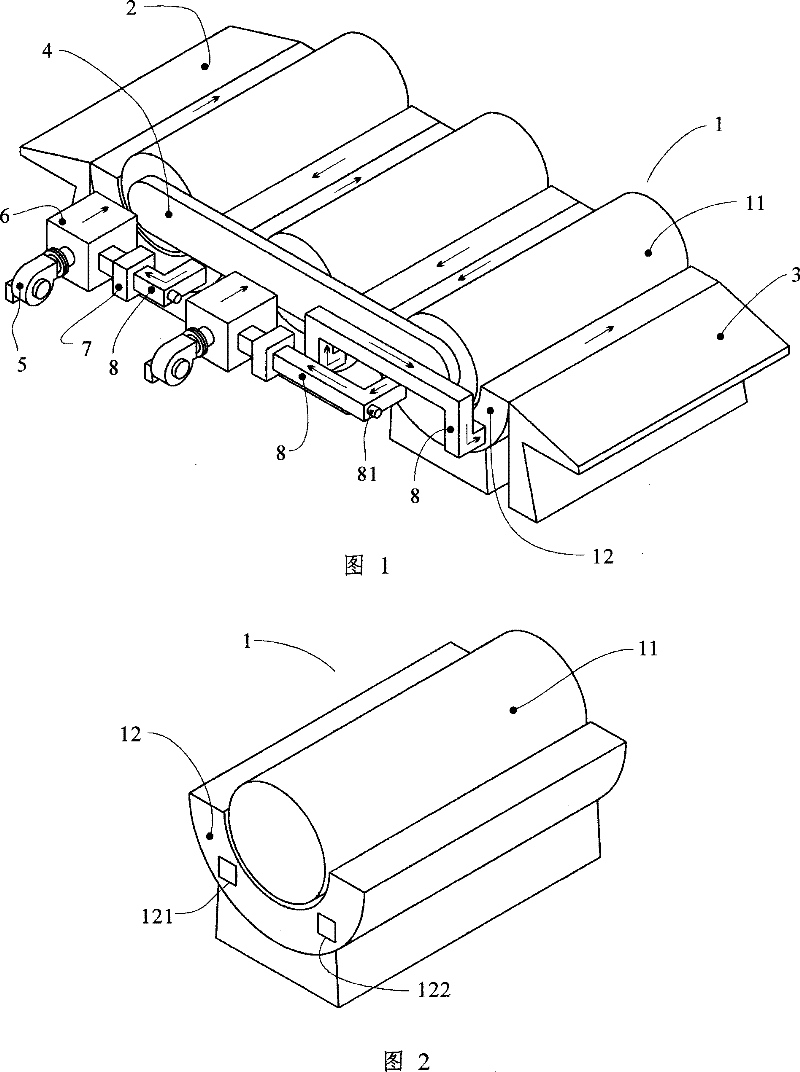

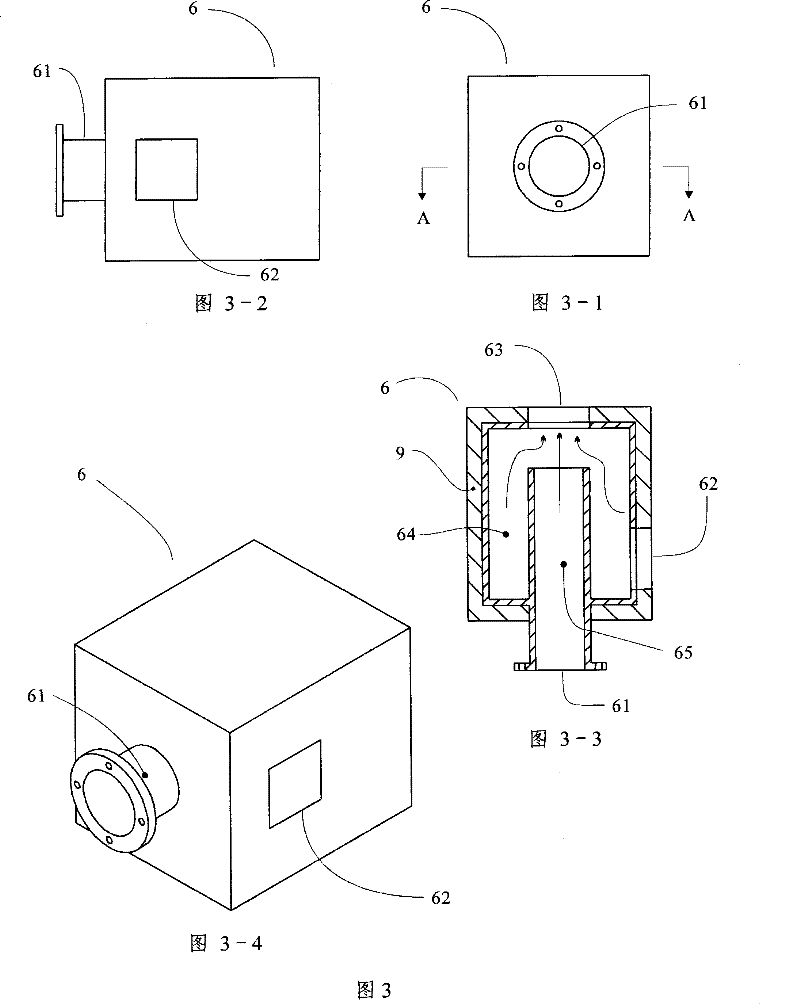

[0056] Design and manufacture a gas-fired large-scale ironing unit, including a feeding platform 2, at least one ironing machine 1, a discharging platform 3 and a transmission mechanism 4, as shown in Figure 1. As shown in FIG. 2 , the ironing machine 1 includes an ironing roller 11 and a heating pot bottom 12 located around the lower half of the ironing roller. Increasing the number of ironing machines 1 will increase the contact time between the textile and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com