Production method of integrated submissive sensor for measuring curve clearance and force

A technology for measuring curved surfaces and compliance, which is applied in the field of sensors and can solve the problems of increased difficulty in processing, measurement and monitoring, and the unrealizable installation position and lead method, etc., to achieve large range, good compliance, high force sensitivity accuracy and resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

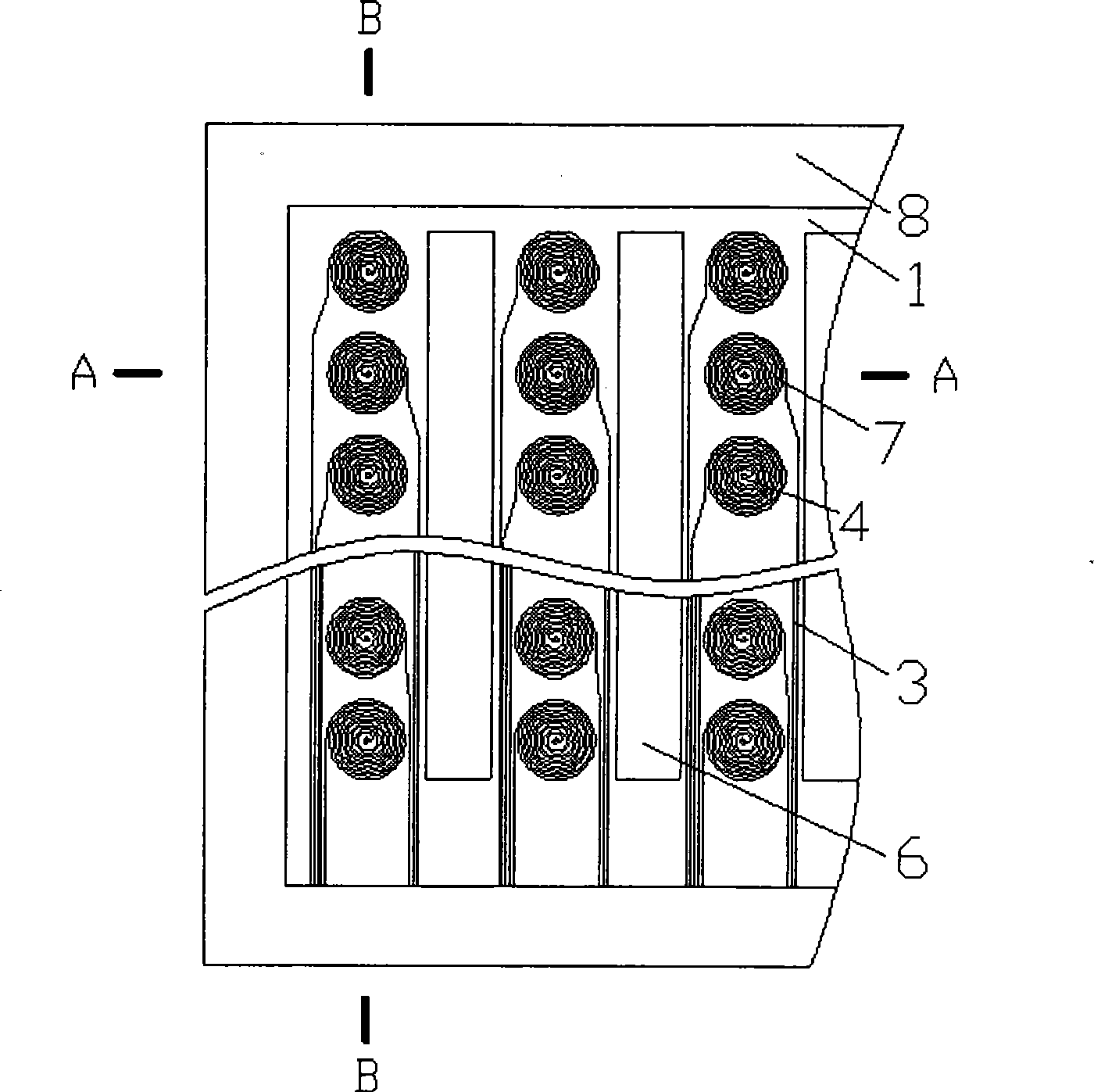

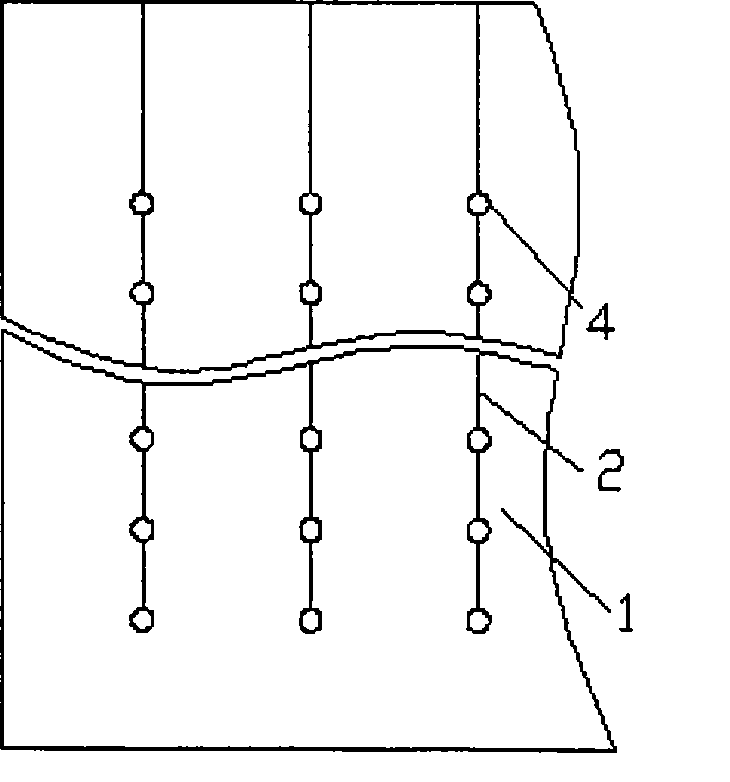

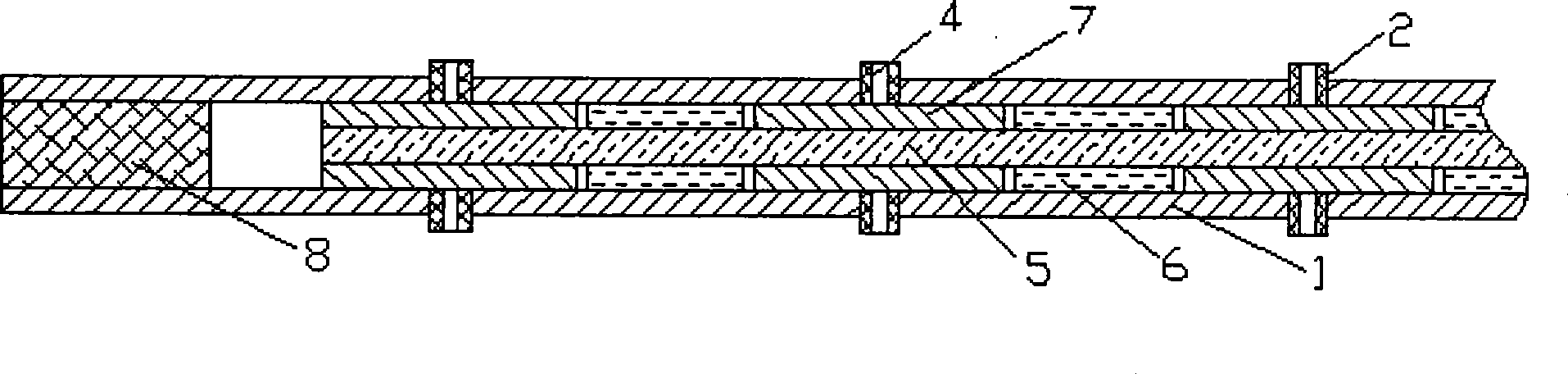

[0039] The preparation method of the integrated compliant sensor for measuring the surface gap and force proposed by the present invention, the front plan view of the sensor before packaging during the preparation process is as follows figure 1 shown, including the following steps:

[0040] (1) Preparation of planar eddy current sensitive elements:

[0041] (1-1) On the polyimide film substrate 1, holes 4 are opened in rows and columns, the thickness of the polyimide film is 100 μm-200 μm, and the aperture of the holes is 250-350 μm;

[0042] (1-2) Copper foil is respectively plated on the front and back surfaces of the polyimide film substrate and the surface of the above-mentioned opening, and the thickness of the copper foil is 15 μm-20 μm;

[0043] (1-3) The above-mentioned reverse copper foil is carried out photoetching, the eddy current coil 7 is formed centering on the above-mentioned opening 4, and the inner lead 3 is formed on one side of each eddy current coil 7, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com