Combined lawn trimmer dislocated knife

A lawn mower and combined technology, applied in lawn mowers, harvesters, agricultural machinery and implements, etc., can solve the problems of no function, waste of kinetic energy, waste of kinetic energy, etc., to achieve strong resistance to obstacles, save energy, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

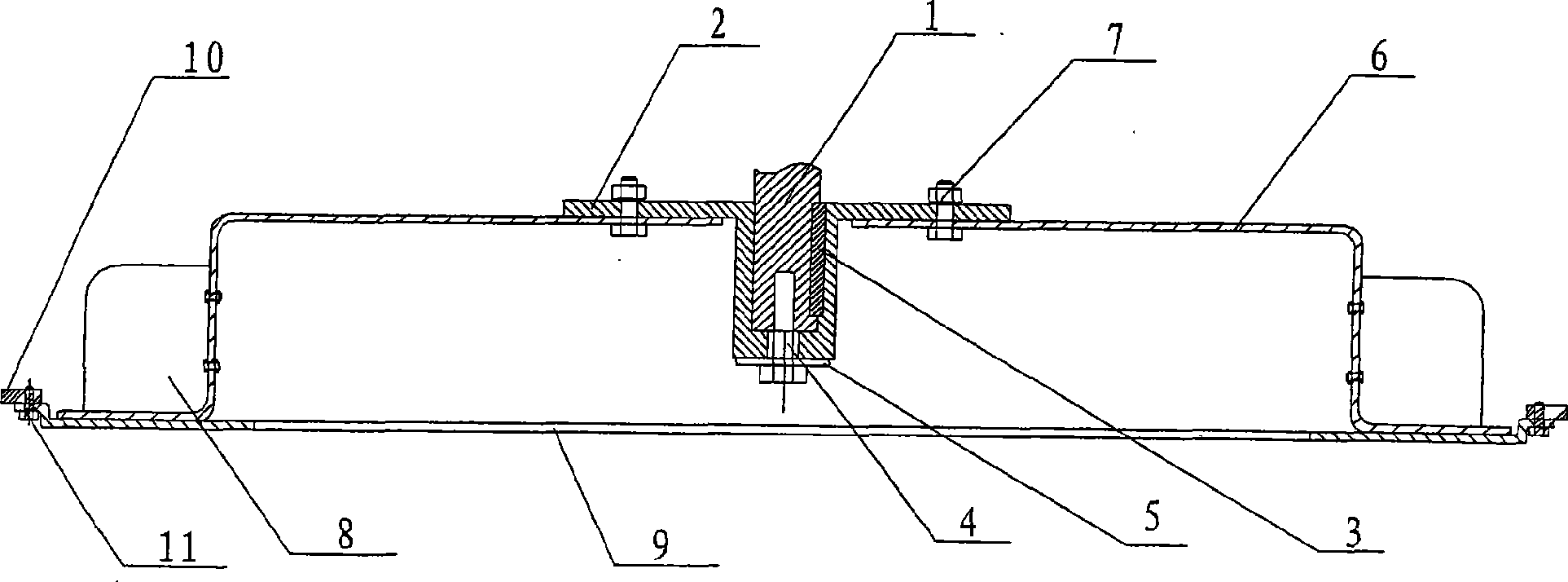

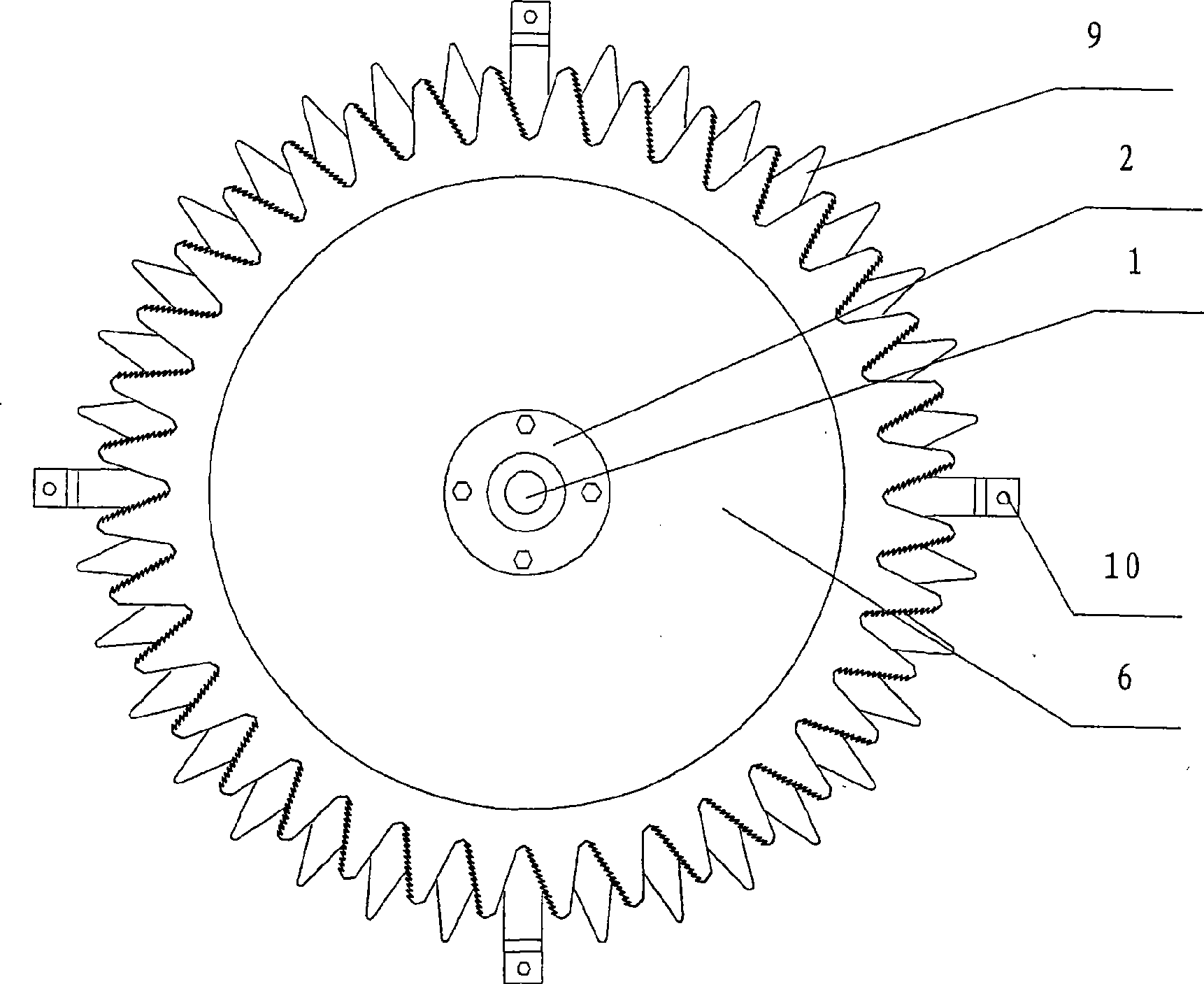

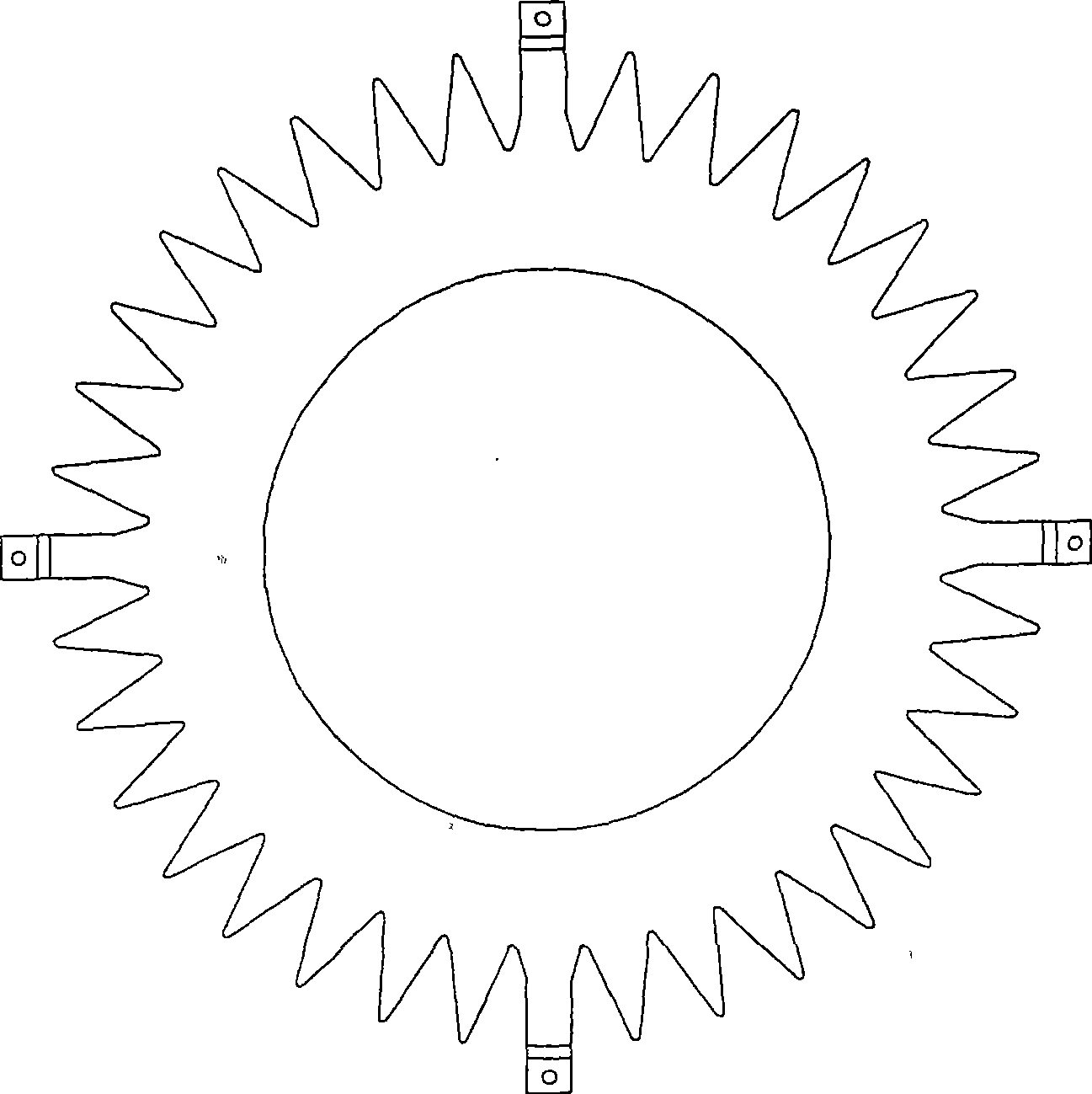

[0016] As shown in the figure, a combined lawn mower dislocation knife includes shaft 1, shaft sleeve 2, key 3, screw 4, gasket 5, moving blade 6, bolt 7, inclined blade 8, static blade 9, hanging Plate 10 and stud 11 etc. There is a shaft sleeve 2 on the shaft 1, the shaft 1 and the shaft sleeve 2 are positioned by the key 3, the shaft 1 and the shaft sleeve 2 are fixed by the screw 4, and the screw 4 is provided with a gasket 5, the shaft sleeve 2 and the The moving blades 6 are connected by bolts 7 , and the moving blades 6 are provided with inclined blades or centrifugal blades 8 , and the inclined blades or centrifugal blades 8 are evenly distributed on the movable blades 6 . Just below the movable blade 6 is provided with a static blade 9, and the hanging plate 10 is welded on the lawn machine chassis, and is connected by a stud 11 between the hanging plate 10 and the static blade 9.

[0017] The rotation of shaft 1 drives the moving blade 6 to rotate, and the static bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com