Liquid dairy food containing omega-3 unsaturated fatty acid and method for producing the same

A technology of unsaturated fatty acids and dairy products, which is applied in the field of liquid dairy products, can solve problems such as the limitation of the application range of omega-3 long-chain polyunsaturated fatty acids, the influence of the properties of milk beverage products, and inappropriate processing technology, so as to promote the improvement of human body's psychological quality. Vascular health, sub-healthy state of nourishing the brain and improving intelligence, and the effect of expanding the sales cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

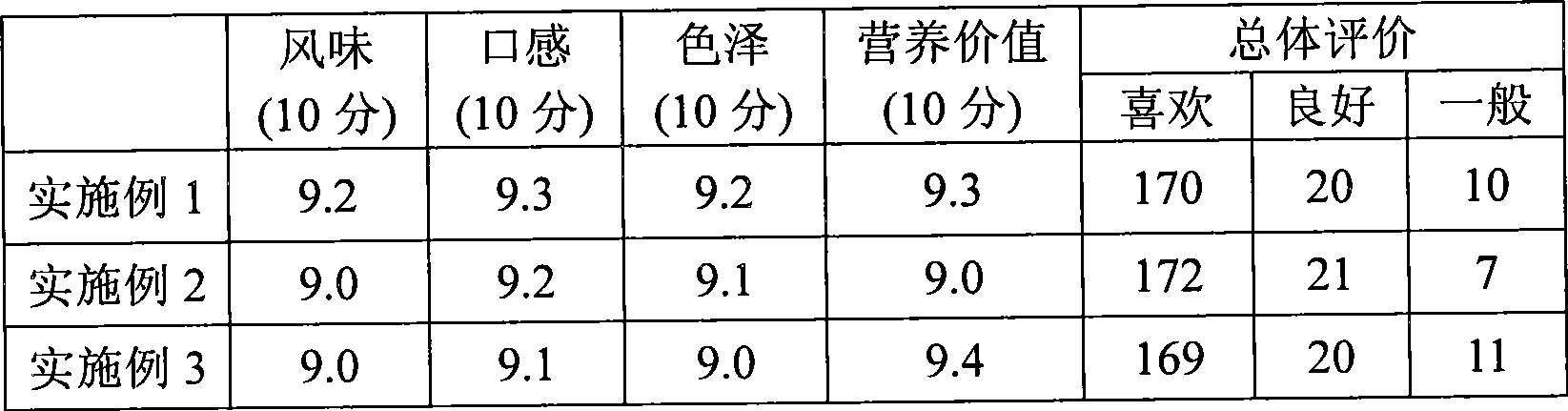

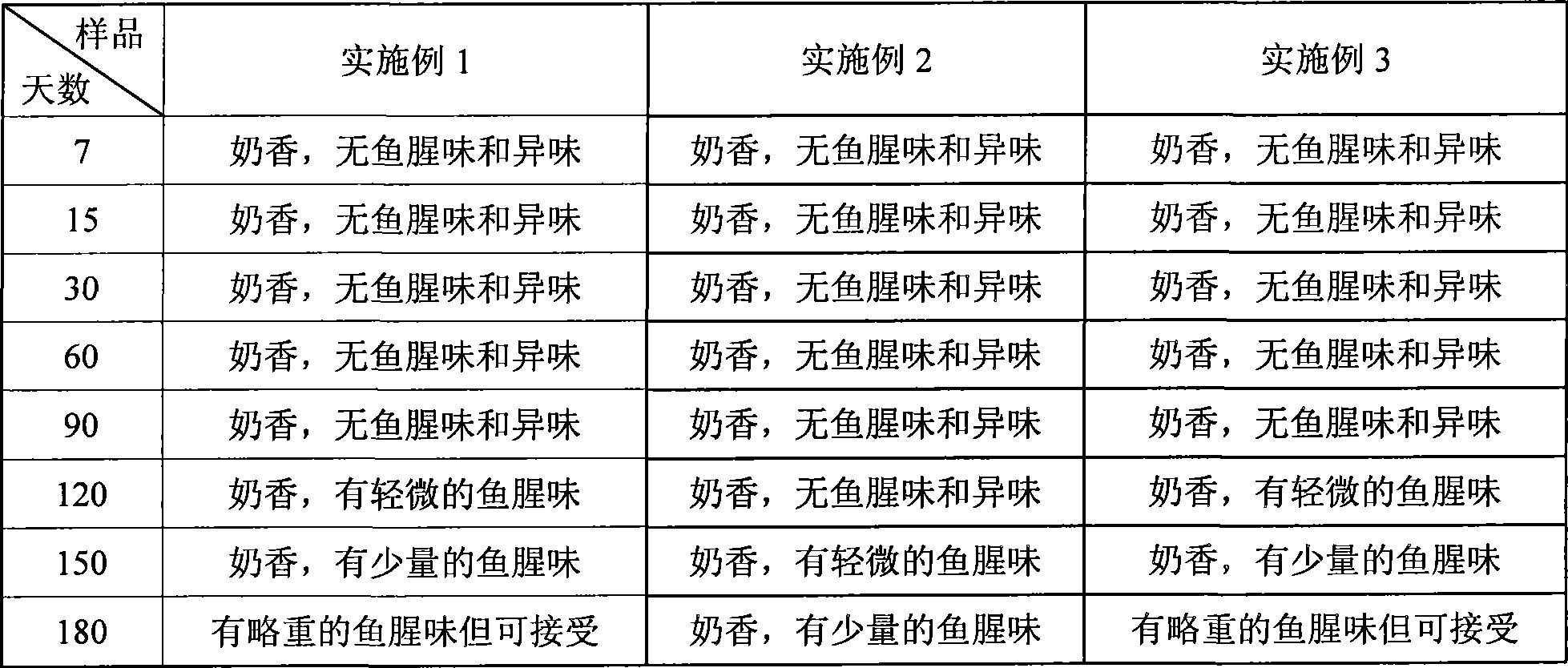

Examples

Embodiment 1

[0043] Formula: 994 parts of milk, 5 parts of omega-3 unsaturated fatty acid, 1 part of monoglyceride;

[0044] Preparation steps:

[0045] (1) Pasteurize the purified raw liquid milk at 72°C for 10 seconds; then cool the pasteurized raw liquid milk to below 8°C to obtain pasteurized raw milk;

[0046] (2) Take part of the cooled pasteurized raw milk, add monoglyceride, mix and stir evenly, then add the mixed milk to the remaining pasteurized raw milk to form a formulated milk composition, raise the temperature to 65°C, Homogenize under pressure; sterilize the homogenized formulated milk composition at 121°C for about 4 seconds, and then cool it below 25°C to make aseptic liquid milk;

[0047] (3) Utilize a filter membrane with a pore size of 0.2-0.3 μm to sterilize the omega-3 unsaturated fatty acid, and then sterilize the omega-3 unsaturated fatty acid again by irradiating ultraviolet light for 20-30s,

[0048] (4) Add sterile omega-3 unsaturated fatty acids to the cooled ...

Embodiment 2

[0050] Formula: 600 parts of milk, 2 parts of omega-3 unsaturated fatty acid, 2 parts of sucrose fatty acid ester, and 396 parts of ingredient water;

[0051] Preparation steps:

[0052] (1) Take raw milk whose temperature does not exceed 8°C, and remove mechanical impurities in the raw milk through a milk cleaning process to obtain raw liquid milk; then pasteurize the raw liquid milk after cleaning at 85°C for 5 seconds and then cooling the pasteurized raw liquid milk to below 8°C to obtain pasteurized raw milk;

[0053] (2) Take part of the cooled pasteurized raw milk, add sucrose fatty acid ester, mix and stir evenly, add the mixed milk to the remaining pasteurized raw milk to become a formulated milk composition, heat up to 70°C, Homogenize under mass pressure; sterilize the homogenized formulated milk composition at 137°C for about 4s, and then cool it below 25°C to make aseptic liquid milk;

[0054] (3) First, use a membrane with a pore size of 0.2-0.3 μm to sterilize ...

Embodiment 3

[0057] Formula: 350 parts of milk, 10 parts of omega-3 unsaturated fatty acids, 1.2 parts of sodium carboxymethylcellulose, 1 part of lactic acid, 2.5 parts of citric acid, 0.5 parts of essence, 50 parts of white sugar, and 584.8 parts of ingredient water;

[0058] Preparation steps:

[0059] (1) Take raw milk with a temperature not exceeding 8°C, remove mechanical impurities in the raw milk through a milk cleaning process, and obtain raw liquid milk; then pasteurize the purified raw liquid milk at 85°C for 5 seconds; Then cooling the pasteurized raw liquid milk to below 8°C to obtain pasteurized raw milk;

[0060] (2) Prepare aseptic liquid milk:

[0061] (1) White granulated sugar and sodium carboxymethyl cellulose (CMC) are mixed evenly, take appropriate batching water and be heated to 80 ℃, slowly add the mixture of this white granulated sugar and CMC, constantly stir and dissolve 25 minutes, be cooled to 35 ℃, Pour into the batching tank and mix well with the pasteurize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com