Golf tee and method for producing the same

A technology for golf tees and manufacturing methods, applied to golf balls, golf clothes, golf accessories, etc., can solve the problems of insufficient strength, inability to achieve mass production, low production efficiency, etc., and achieve high wear resistance and chemical stability , Improve the appearance and ornamental value, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The golf tee of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

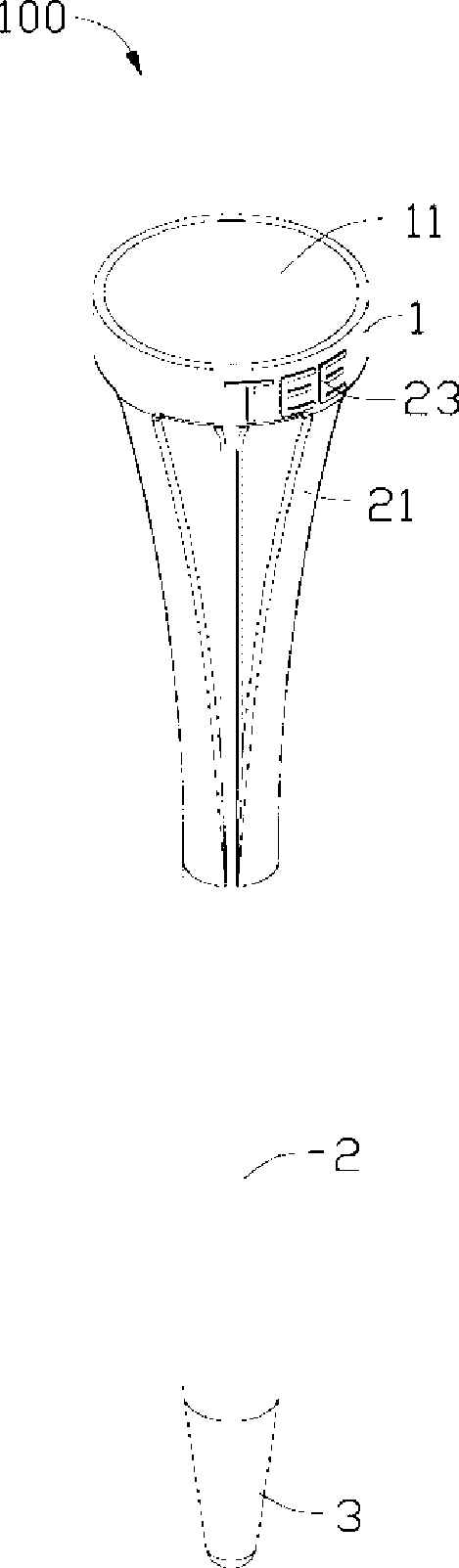

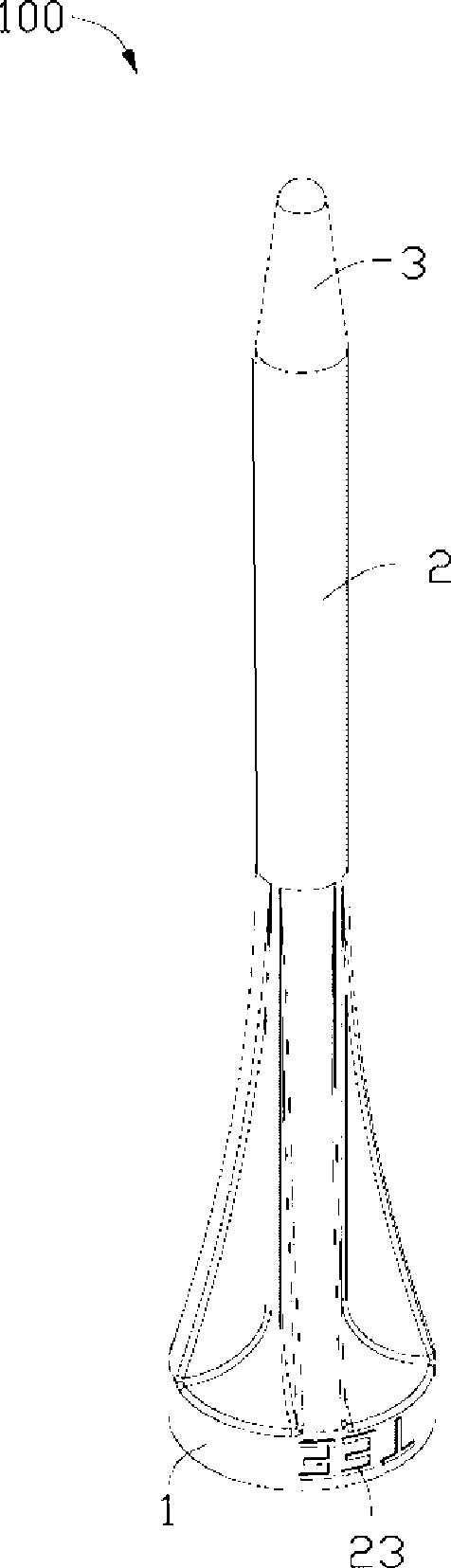

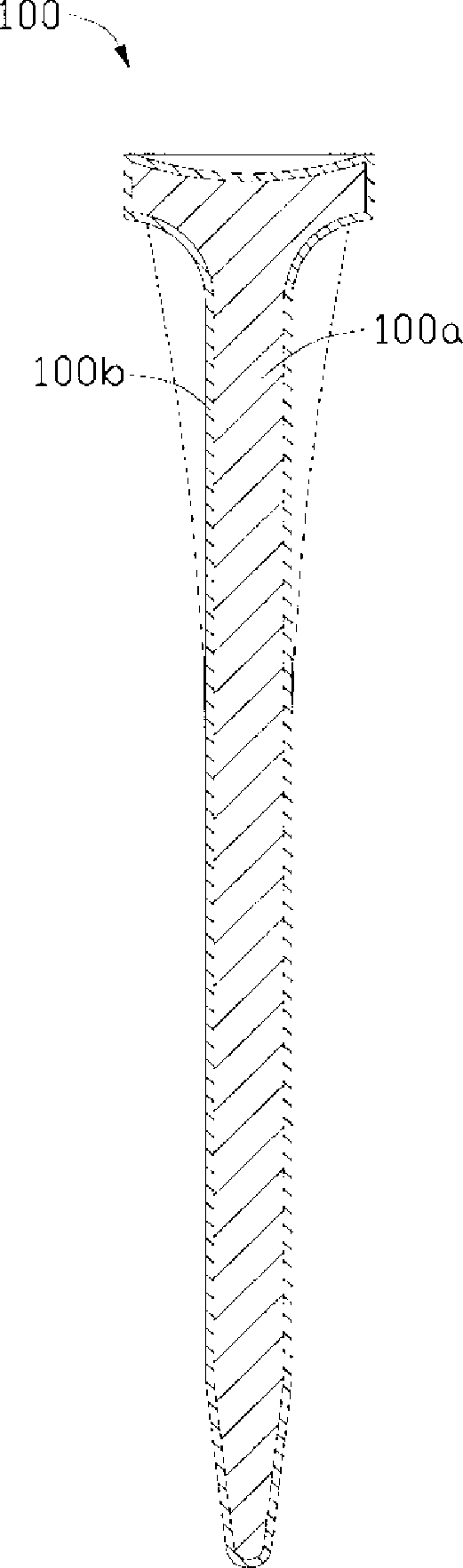

[0025] See figure 1 and figure 2 , The golf tee 100 according to the preferred embodiment of the present invention includes a ball holder 1, a spike 2 and an awl 3 at the end of the spike 2, and the ball holder 1, the spike 2 and the awl 3 are integrally formed.

[0026] The ball holder 1 is flat and cylindrical, and its top is provided with a spherical depression 11. The main function of the depression 11 is to support the golf ball. There are four equidistantly distributed reinforcement strips 21 between the ball holder 1 and the nail foot 2, and the reinforcement strips 21 mainly strengthen the transition strength between the ball holder 1 and the nail foot 2, preventing it from being interrupted when hitting the ball . The cone tip 3 is conical, and its function is to facilitate the insertion of the entire golf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com