Composite filtering type filtering bottle

A composite filtration and filter bottle technology, applied in the direction of filtration circuit, filtration separation, fixed filter element filter, etc., can solve the problems of difficult installation and maintenance, many water inlets and outlets, and large space occupation, so as to reduce the occurrence of water leakage. Probability, beautiful and practical appearance, the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment, the present invention will be further described; Following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

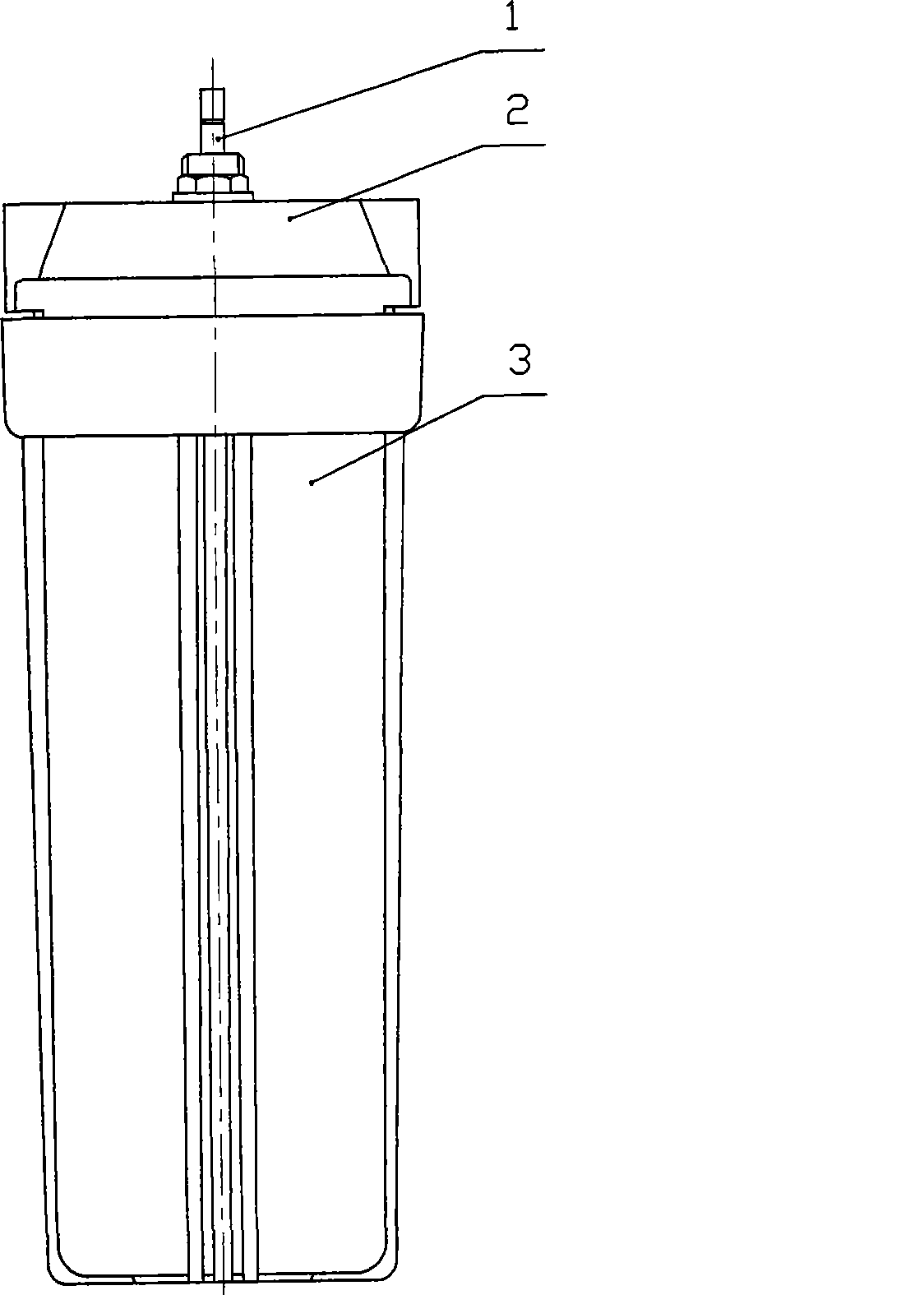

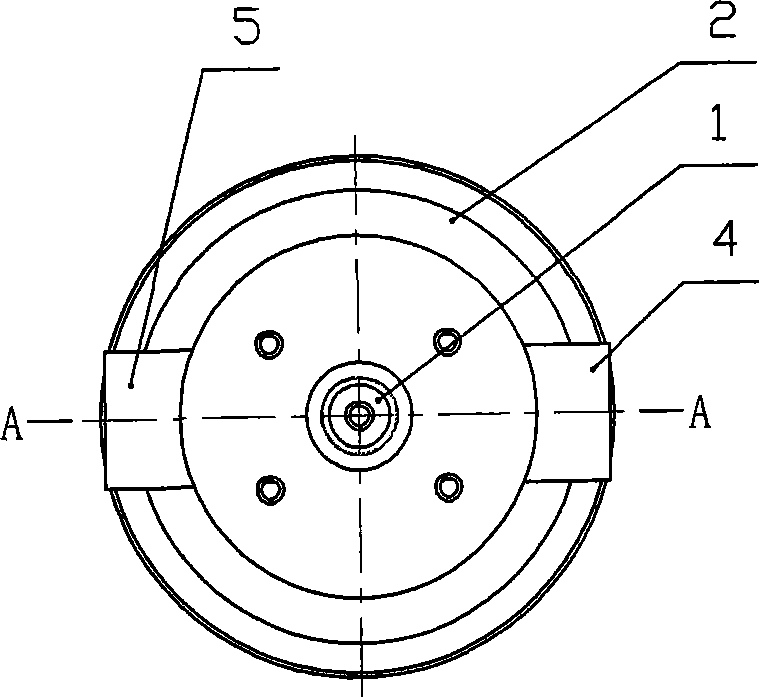

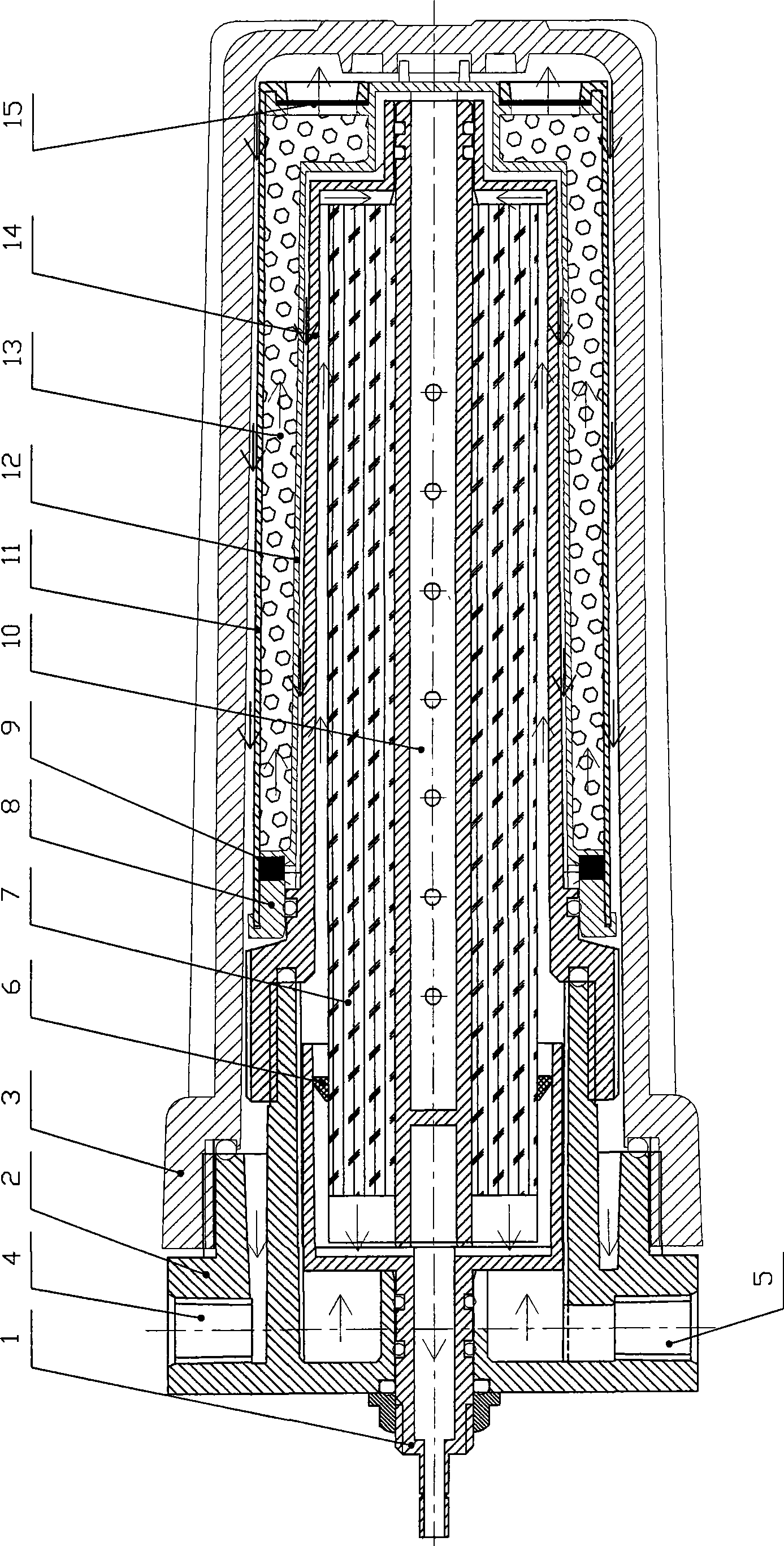

[0021] A compound filtration type filter bottle, which is composed of an upper cover 2, a jacket 3, a membrane end cover 1, a reverse osmosis membrane 7, a water inlet 5, and a water outlet 4. The upper cover and the membrane end cover are locked by a lock nut (the lock nut does not have label), the membrane end cover and the reverse osmosis membrane are installed coaxially, and are sealed and embedded into the upper cover, the central hole of the membrane end cover is coaxial with the central tube 10 of the reverse osmosis membrane, and the upper end of the central tube is connected The central hole of the tank is connected and is the outlet of concentrated water; the upper cover is sealed and installed with the outer cover through thread engagement,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com