Fuel injection control device for engine

A technology of fuel injection and control device, which is applied in the direction of fuel injection device, fuel injection control, engine control, etc., and can solve problems such as being unable to be a solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

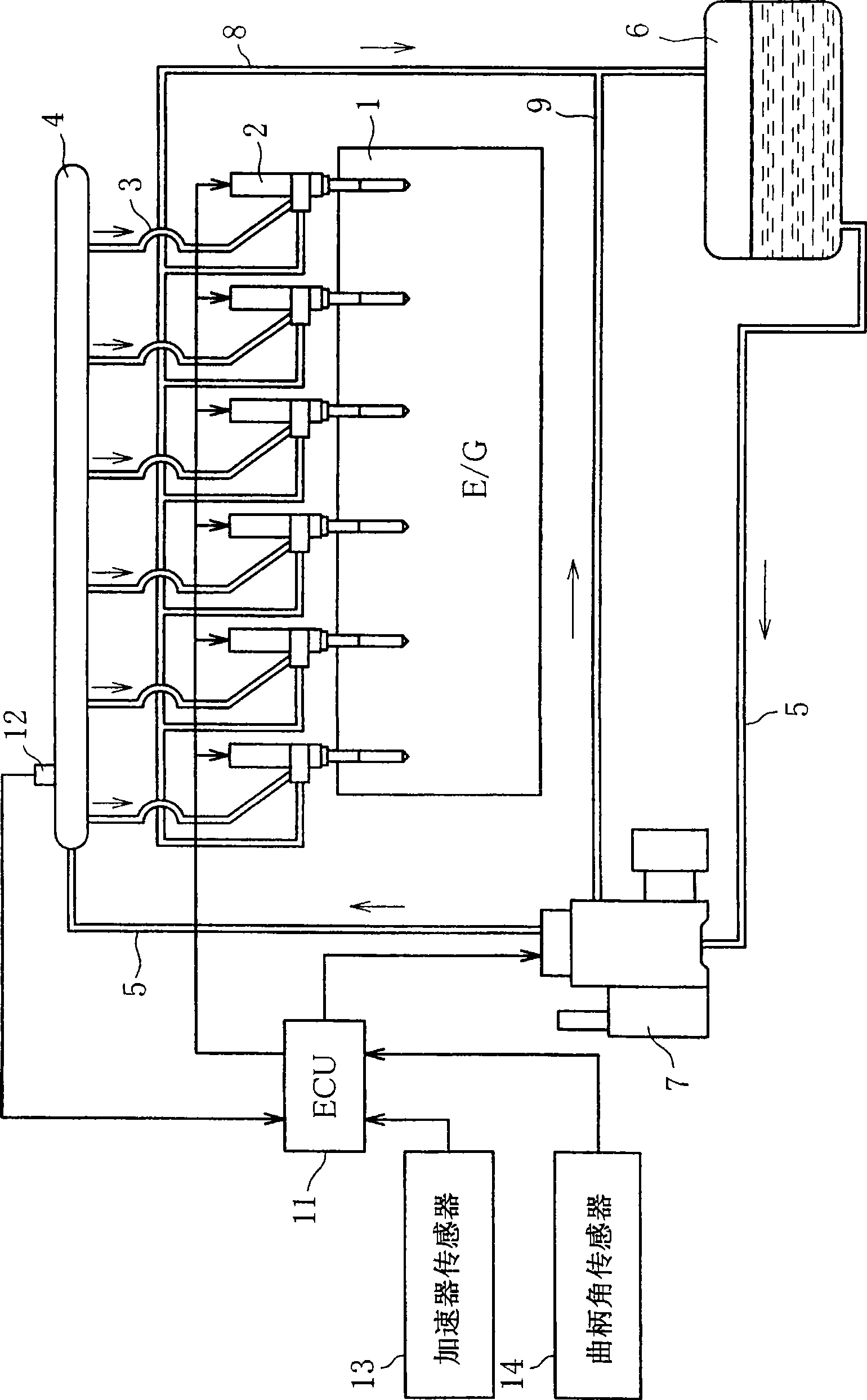

[0026] Next, a fuel injection control device for an engine according to an embodiment of the present invention will be described with reference to the drawings.

[0027] figure 1 is an overall configuration diagram showing a fuel injection control device for an engine according to the present embodiment. In the present embodiment, the engine 1 is configured as an in-line 6-cylinder diesel engine mounted on a vehicle. A fuel injection valve (fuel injection unit) 2 is provided on each cylinder of the engine 1 .

[0028] Each fuel injection valve 2 is connected to a common fuel rail (fuel supply unit) 4 via a fuel distribution line 3 . The common fuel rail 4 is connected to a fuel tank 6 of the vehicle via a fuel pressure feed line 5 . In the fuel pressure-feeding line 5, a supply pump 7 constituted by a positive displacement plunger pump is provided. As is well known, the charge pump 7 is driven in synchronization with the rotation of the engine 1, pressurizes the fuel from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com