Preparation method of hydrophobic film with slidable liquid locked on surface

A hydrophobic film and hydrophobic film technology are applied in the field of preparation of hydrophobic films, which can solve the problems of easy freezing and destruction of hydrophobicity, reduction, and easy destruction of micro-nano pore structure, etc. Effect of injection rate and performance promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

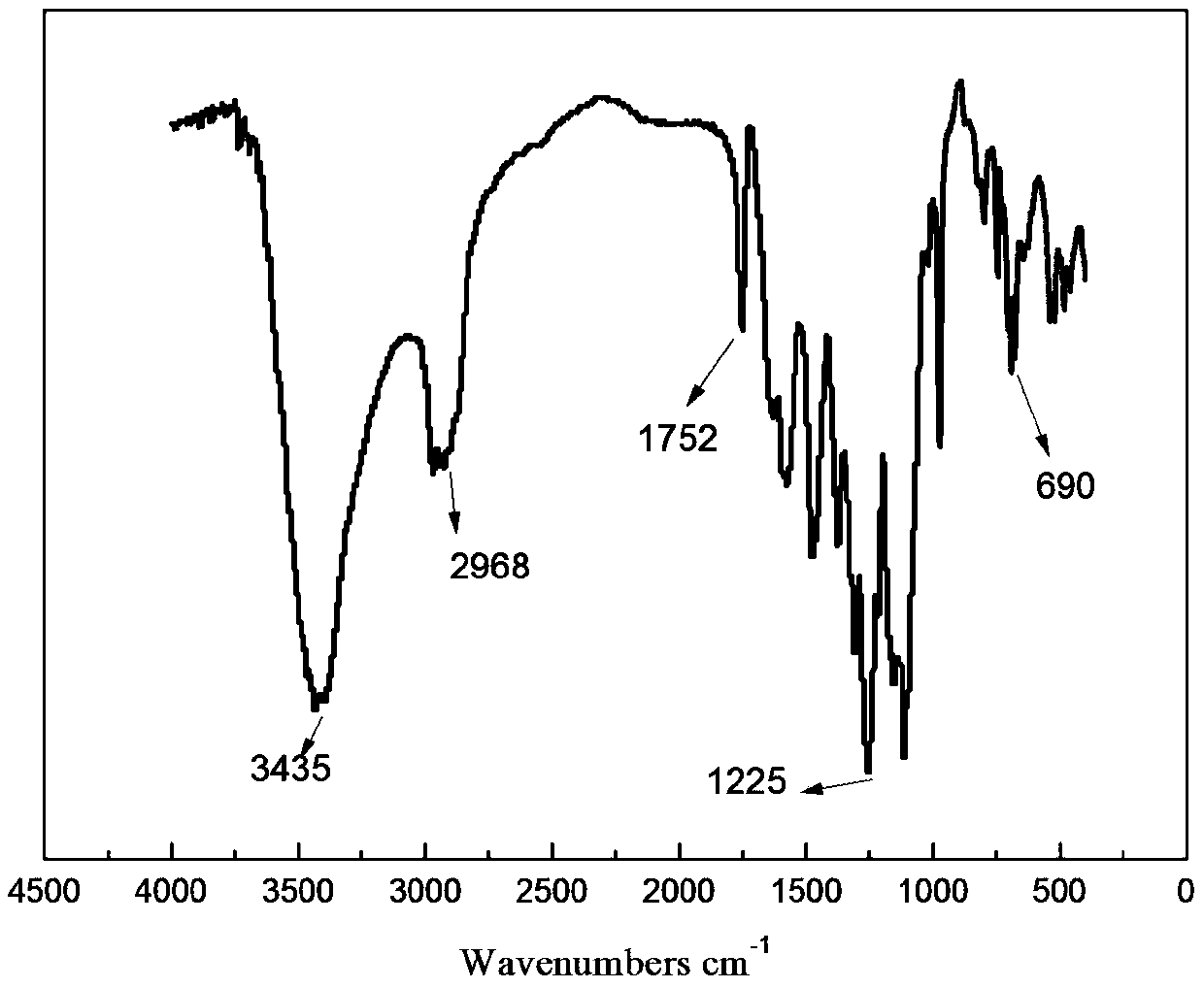

[0046] (1) Preparation of macroinitiator PDFHMA-Br by atom transfer radical polymerization

[0047] Weigh 0.1406g of 2,2'-bipyridine and 0.0297g of CuCl into the gram flask, then pat the wall of the bottle under vacuum and nitrogen to make the solid complex, then inject 5mL DMF, (vacuum nitrogen, gently Tap the bottle wall) repeatedly for three times, use a micro-sampler to measure 43.3 μl of ethyl 2-bromoisobutyrate and add it to the gram bottle, use a syringe to measure 3.8 mL of the reaction monomer dodecafluoroheptyl methacrylate and add The gram flask was evacuated three times with nitrogen gas, and reacted at 100°C for 24 hours, then cooled with liquid nitrogen for 30 seconds, added tetrahydrofuran to the reaction system for ultrasonic dissolution, rinsed with a perbasic alumina column, and washed with methanol The mixed solution with water is the precipitated product of the precipitant, which is suction filtered and dried to obtain the macromolecular initiator PDFHMA-Br...

Embodiment 2

[0057] (1) the method that ATRP method prepares macromolecular initiator is with embodiment 1;

[0058] (2) The method for preparing the amphiphilic block copolymer polydodecafluoroheptyl methacrylate-b-polyhydroxyethyl methacrylate (PDFHMA-b-PHEMA) is the same as in Example 1;

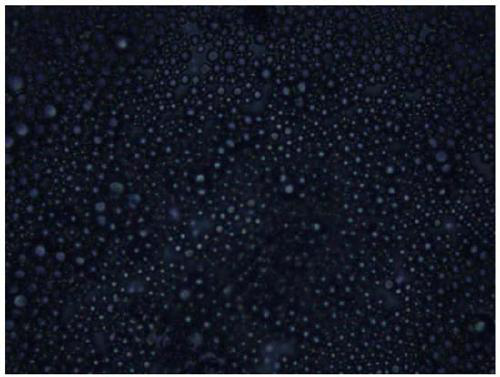

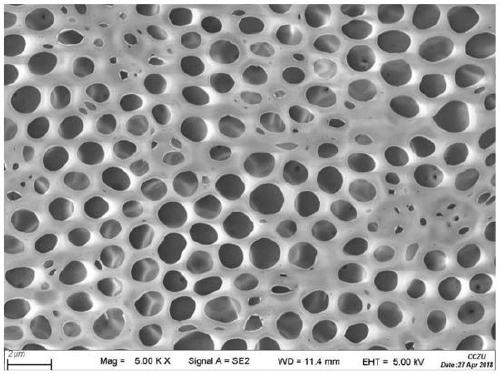

[0059] (3) the method for preparing superhydrophobic porous film is the same as embodiment 1;

[0060] (4) Infuse silicone oil to prepare a hydrophobic film that locks oil on the surface

[0061] The hydrophobic porous film obtained in step (3) was immersed in silicone oil at room temperature for 3 days so that the silicone oil was fully infused into the pores, and then vacuum-dried in a normal temperature drying oven for 1 day. After complete infusion, the samples were then placed vertically in a laboratory environment for approximately 6 hours to drain excess fluid. In order to avoid the presence of un-locked silicone oil on the surface, cover the surface with thin filter paper and press gently to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com