A kind of wet polyacrylonitrile flat ultrafiltration membrane and preparation method thereof

A technology of polyacrylonitrile and polyacrylonitrile resin, which is applied in the field of ultrafiltration membranes, can solve the problems of low water flux of PAN ultrafiltration membranes, high price of PVDF, and weak selective permeability, etc., and achieves a combination of water flux and Retention performance, ease of large-scale industrial production, effect of high water flux and retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

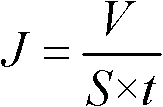

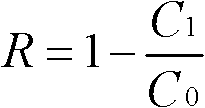

[0026] The polyacrylonitrile resin with a molecular weight of 50,000 was dried for subsequent use; 18.0 g of the polyacrylonitrile resin was dissolved in 76.0 g of N, N-dimethylacetamide, and then 5.0 g of molecular weight was added with polyethylene glycol of 1000 and 1.0 g of Silicon dioxide with a particle size of 100 μm was heated and stirred under the protection of nitrogen (0.15MPa) at 80°C for 24 hours, and then degassed at this temperature for 24 hours to obtain a quaternary casting solution; the above-mentioned quaternary casting solution was scraped Made on a smooth glass plate, and volatilized in the air for 60 seconds, then immersed in the first constant temperature gel bath at 40°C for 30 minutes, and then immersed in the second constant temperature gel bath at 40°C for 30 minutes, at this time Polyacrylonitrile produces gelation; then the membrane is taken out and soaked in ultrapure water for 36 hours, drenched and then soaked in glycerin for 36 hours; after dryi...

Embodiment 2

[0028] The polyacrylonitrile resin with a molecular weight of 90,000 was dried for subsequent use; 16.0 g of the polyacrylonitrile resin was dissolved in 74.5 g of N,N-dimethylacetamide, and then 8.0 g of molecular weight was added with polyethylene glycol of 400 and 1.5 g of Aluminum oxide with a particle size of 60 μm was heated and stirred under the protection of nitrogen (0.1MPa) at 80°C for 24 hours, and then degassed at this temperature for 24 hours to obtain a quaternary casting solution; scrape the above quaternary casting solution Put it on a smooth glass plate and volatilize in the air for 60 seconds, then immerse it in the first constant temperature gel bath at 40°C for 30 minutes, and then immerse it in the second constant temperature gel bath at 40°C for 30 minutes. Acrylonitrile produces gelation; then the membrane is taken out and soaked in ultrapure water for 36 hours, and then soaked in glycerin for 36 hours after drying the water; after drying the excess glyce...

Embodiment 3

[0030] The polyacrylonitrile resin with a molecular weight of 50,000 was dried for subsequent use; 20.0 g of the polyacrylonitrile resin was dissolved in 74.0 g of ethylene carbonate, and then 5.0 g of polyethylene glycol with a molecular weight of 2000 and 1.0 g of polyacrylonitrile with a particle size of 40 μm were added. Lithium oxide was heated and stirred under the protection of nitrogen (0.15MPa) at 80°C for 24 hours, and then degassed at this temperature for 24 hours to obtain a quaternary casting solution; the above-mentioned quaternary casting solution was scraped on a smooth glass plate, And volatilized in the air for 60 seconds, then immersed in the first constant temperature gel bath at 40°C for 30 minutes, and then immersed in the second constant temperature gel bath at 40°C for 30 minutes, at this time polyacrylonitrile gelled Then the membrane was taken out and soaked in ultrapure water for 36 hours, drenched and then soaked in glycerin for 36 hours; after dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com