Method for measuring positive pressure leak hole leak rate

A positive pressure leak, measurement method technology, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of long measurement time, measurement uncertainty, large uncertainty, etc. problems, to achieve the effect of small measurement uncertainty, improve work efficiency, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

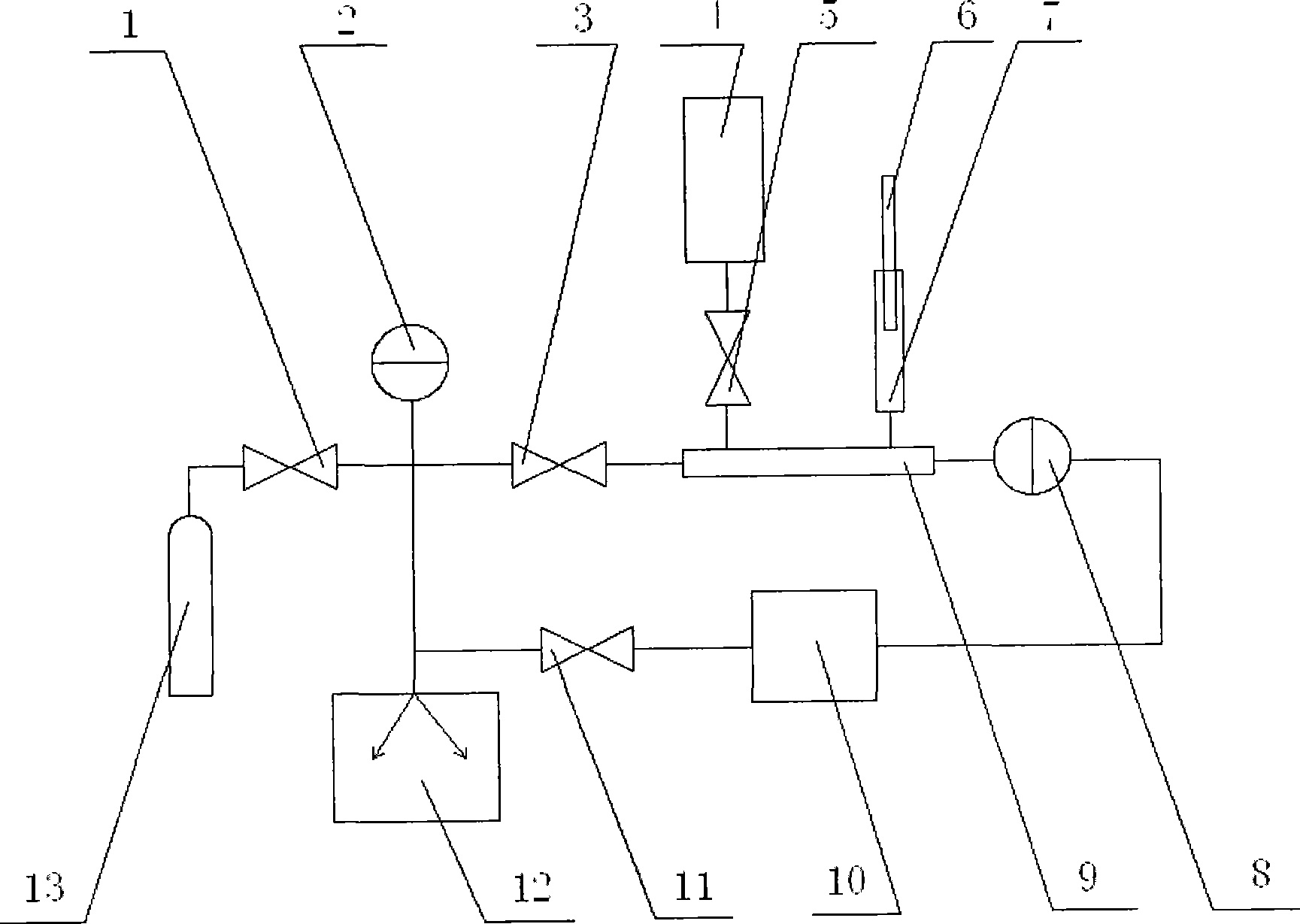

[0029] Such as figure 1 Shown, the measuring device of the leak rate of positive pressure leak that the present invention adopts is by vacuum valve 1,3,5,11, absolute pressure gauge 2, positive pressure leak 4, piston 6, variable capacity chamber 7, differential pressure type A pressure gauge 8, a variable volume chamber main body 9, a standard container 10, a vacuum pump 12, and a gas cylinder 13 are formed.

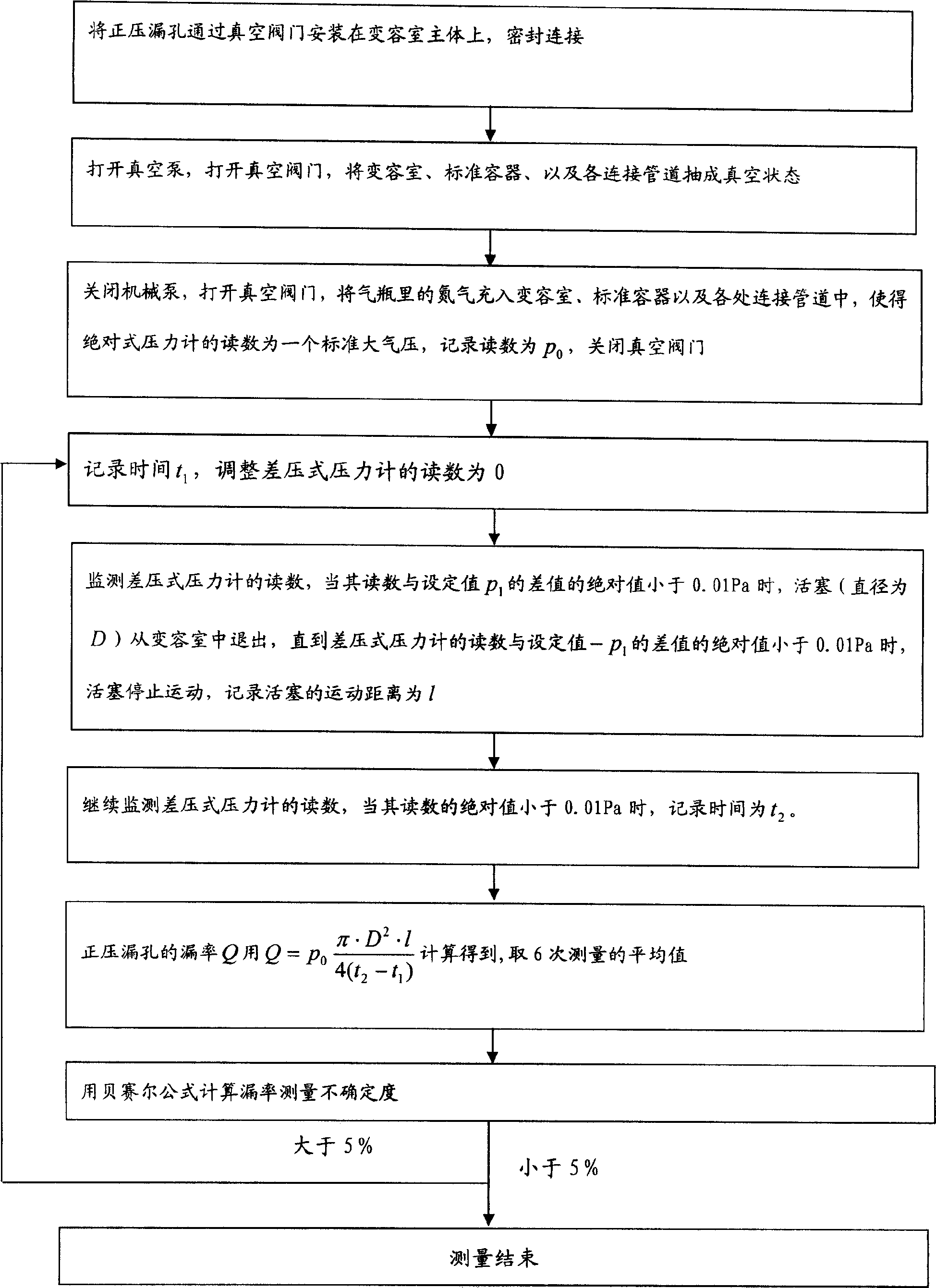

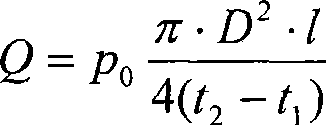

[0030] The specific steps are:

[0031] (1) Install the positive pressure leakage hole 4 on the main body 9 of the variable volume chamber through the vacuum valve 5 .

[0032] (2) Open the vacuum pump 12, open the vacuum valves 3 and 11, and the variable volume chamber 7 (volume 9ml), the standard container 10 (volume 1.1×10 -3 m 3 ), and each connecting pipe is pumped into a vacuum state (vacuum degree is 0.06Pa).

[0033] (3) Close the vacuum pump 12, open the vacuum valve 1, and fill the nitrogen in the gas cylinder 13 into the variable capacity chamber 7, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com