Overcurrent detection circuit, decompression converter and overcurrent detection method

A buck converter, overcurrent detection technology, applied in the direction of measuring current/voltage, measuring electrical variables, instruments, etc., can solve the problems of affecting the current limiting effect, the output current affecting the current limiting effect, etc., to achieve simple and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

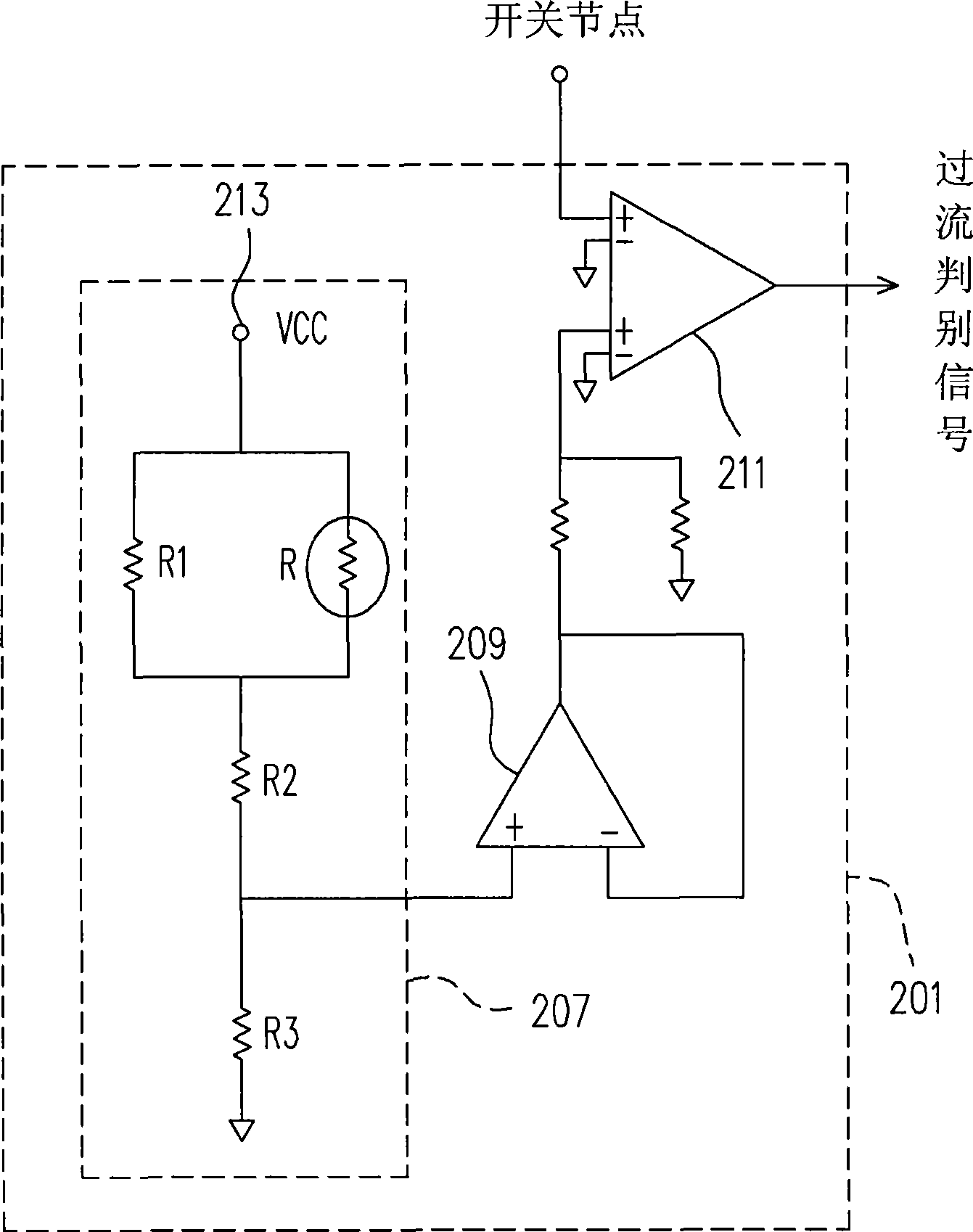

[0028] See figure 2 , which is a schematic structural diagram of an overcurrent detection circuit according to an embodiment of the present invention. The overcurrent detection circuit 201 includes a voltage generation circuit 207 , a voltage follower 209 and an operational amplifier 211 . The voltage generating circuit 207 includes a voltage input terminal 213 , a thermistor R, a first resistor R1 , a second resistor R2 and a third resistor R3 . The first resistor R1 is connected in parallel with the thermistor R and is arranged between the voltage input terminal 213 and the second resistor R2. One end of the second resistor R2 is connected in series with the parallel-connected thermistor R and the first resistor R1, and the other end is used as a reference voltage output end and connected to the third resistor R3. One end of the third resistor R3 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com