Non-mask photo-etching system based on nano lens

A technology of maskless lithography and lens, which is applied in the direction of lens, microlithography exposure equipment, optics, etc., can solve the problems of high system cost and large reduction factor of optical system, and achieve the effect of high pixel resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

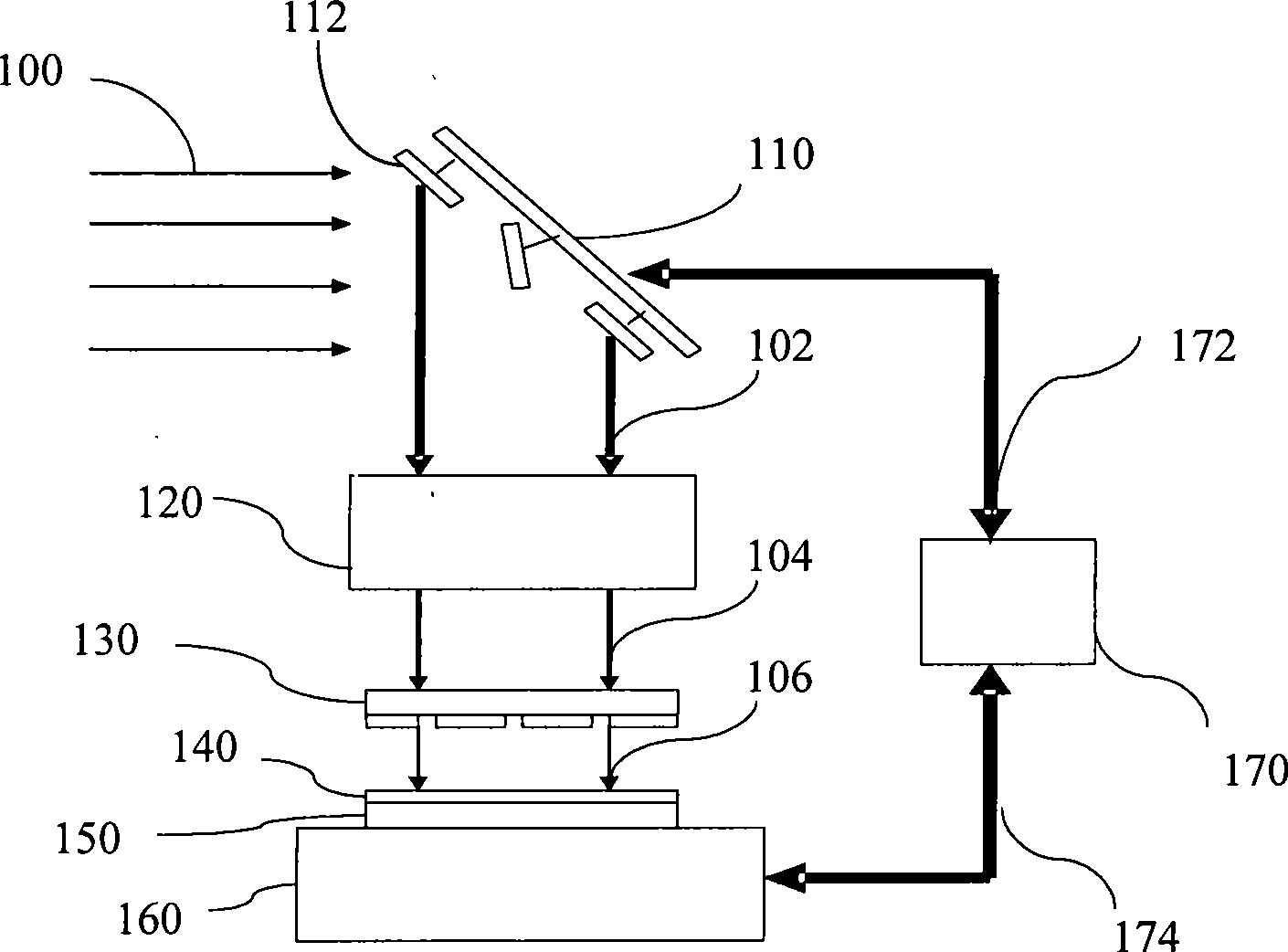

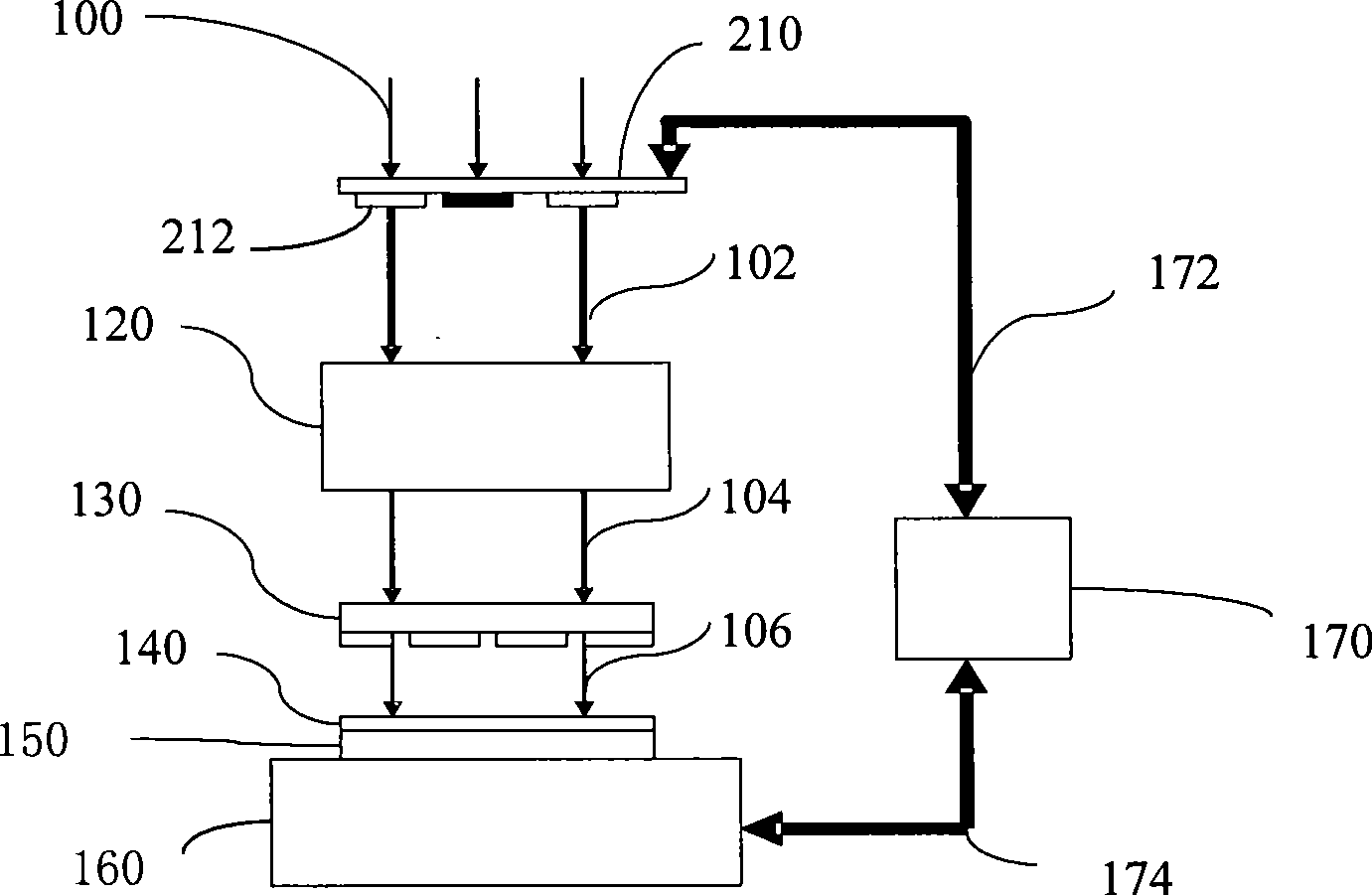

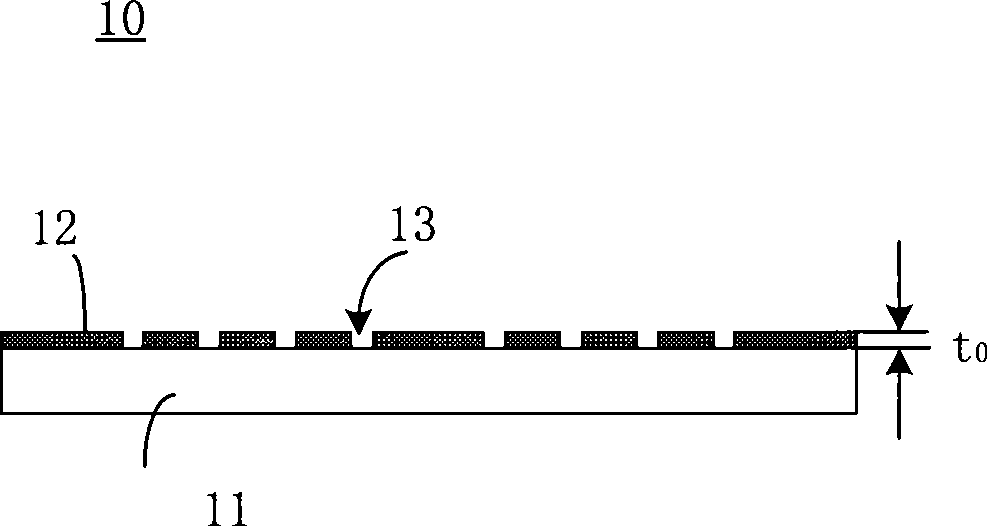

[0037] In current maskless lithography, such as zone plate array lithography, the resolution is mainly limited by the resolution of the microlenses used for focusing. For this reason, the maskless lithography system based on nanolenses proposed by the present invention adopts nanolenses to form a focusing array, and an optical imaging system provides the patterned light beam array required for exposing photoresist on a semiconductor substrate, for example, Each microbeam in the beam array corresponds to a pixel on the semiconductor substrate, and the patterned beam array will control each pixel to be bright or dark according to the exposure pattern to be generated. Each nano-lens in the focusing array corresponds to focusing each micro in the patterned light beam array to project to the semiconductor substrate. The semiconductor substrate is placed on a movable platform, for example, and during exposure, the exposure area on the semiconductor substrate can be selected by movin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com