Poly(fluoride) gear lubricant

A technology of gear lubricating oil and polyfluorine, which is applied in the direction of lubricating composition and petroleum industry, can solve problems such as accidents, different performance requirements of gear lubricating oil, and mechanical failure of users, so as to achieve user convenience, solve easy coking, and broaden The effect of temperature and conditions of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

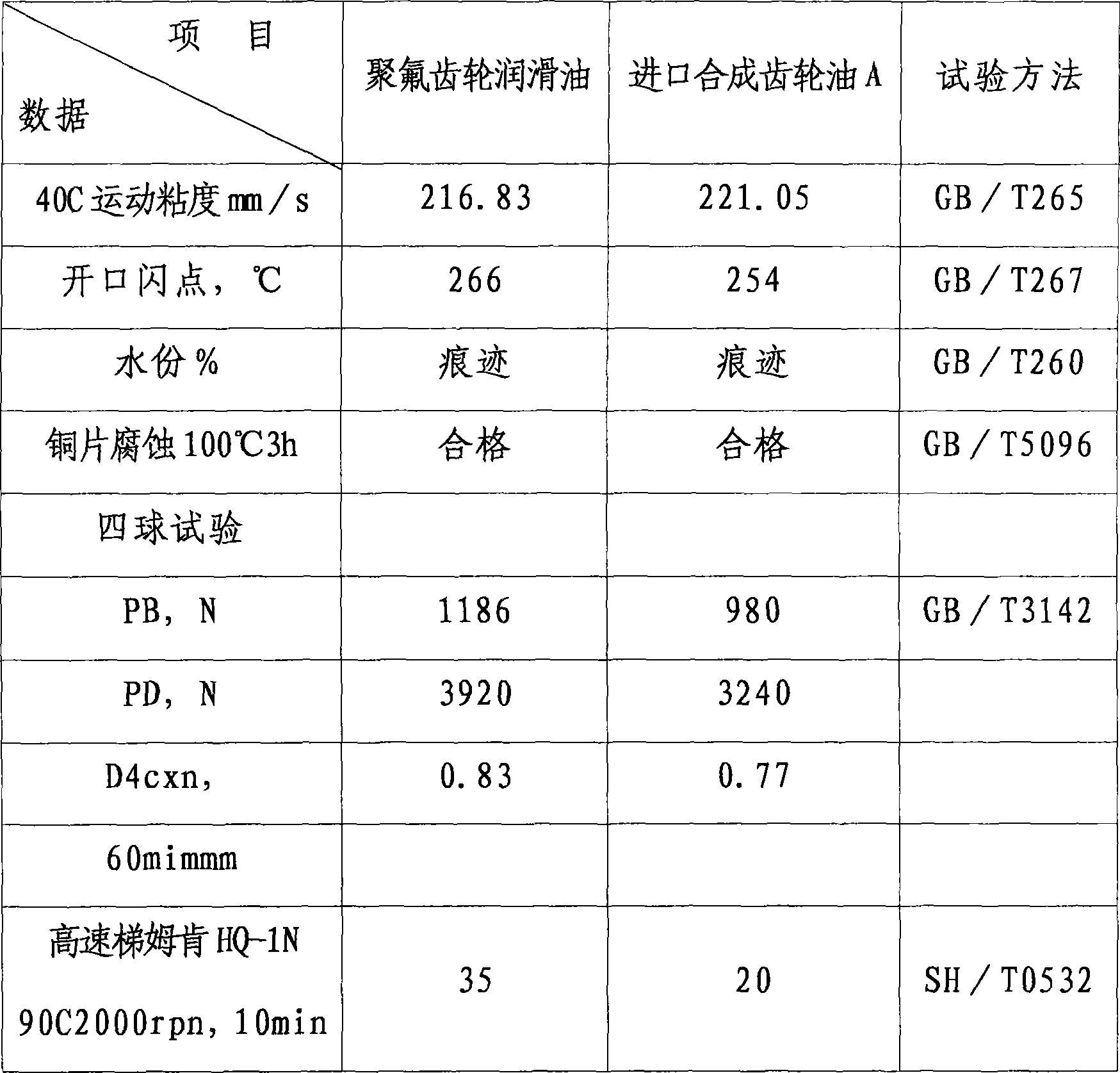

[0015] 1. Comparative test of anti-wear performance:

[0016] 1. Products: polyfluorinated gear lubricant, imported synthetic gear oil A.

[0017] 2. Testing equipment:

[0018] Equipment name Model Specifications Producer Kinematic Viscometer Shanghai Petroleum Instrument Factory Petroleum Pour Point Tester QD8 Tianjin Refrigeration Instrument Factory Open flash point tester SYP Shanghai Petroleum Instrument Factory

[0019] High Speed Timken HQ-1 wenzhou Four ball testing machine MQ800 Jinan Adhesive sheet tester 25B-19N Japan

[0020] 3. Check the test results:

[0021]

[0022] 4. Result analysis: From the analysis of the results of the four-ball test and the high-speed Timken test, the polyfluorinated gear lubricant has better anti-wear performance than the imported synthetic gear oil A.

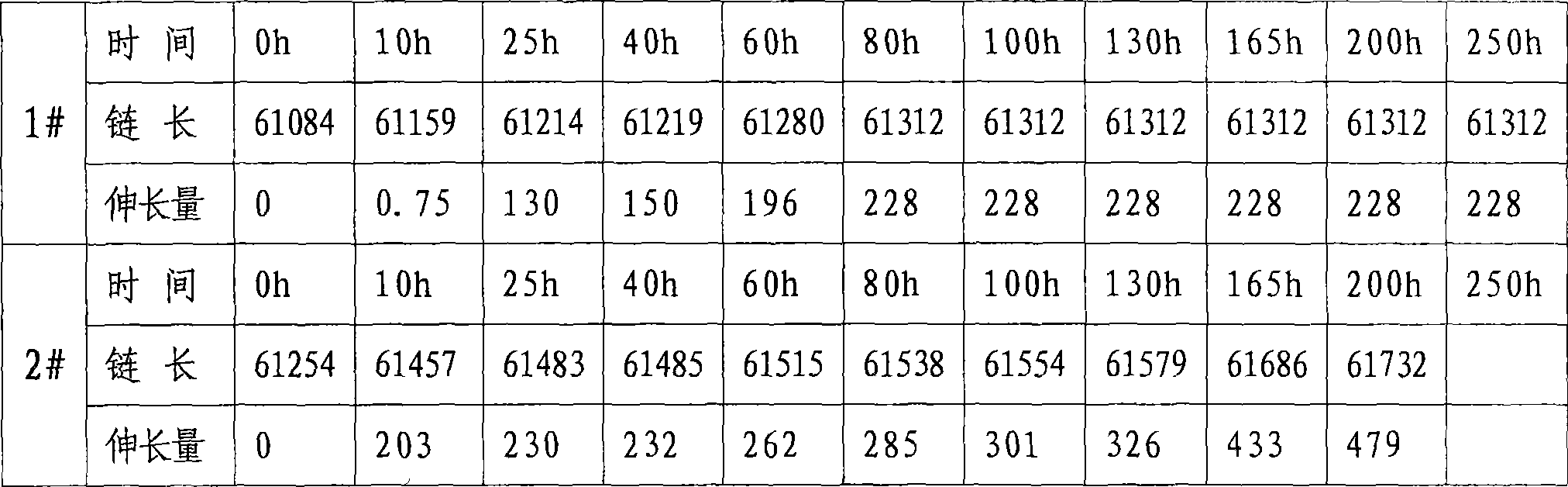

[0023] Second, the comparison test of anti-stretch and extended use time:

[0024] 1. Products: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com