Free two-side turning door

A rollover and free technology, applied in irrigation pipelines, applications, buildings, etc., can solve the problems of large hydraulic loss, limited compression, poor sealing effect, etc., to achieve small water outlet pressure loss, reduce power consumption, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment, the free double-sided flip door of the present invention will be further described:

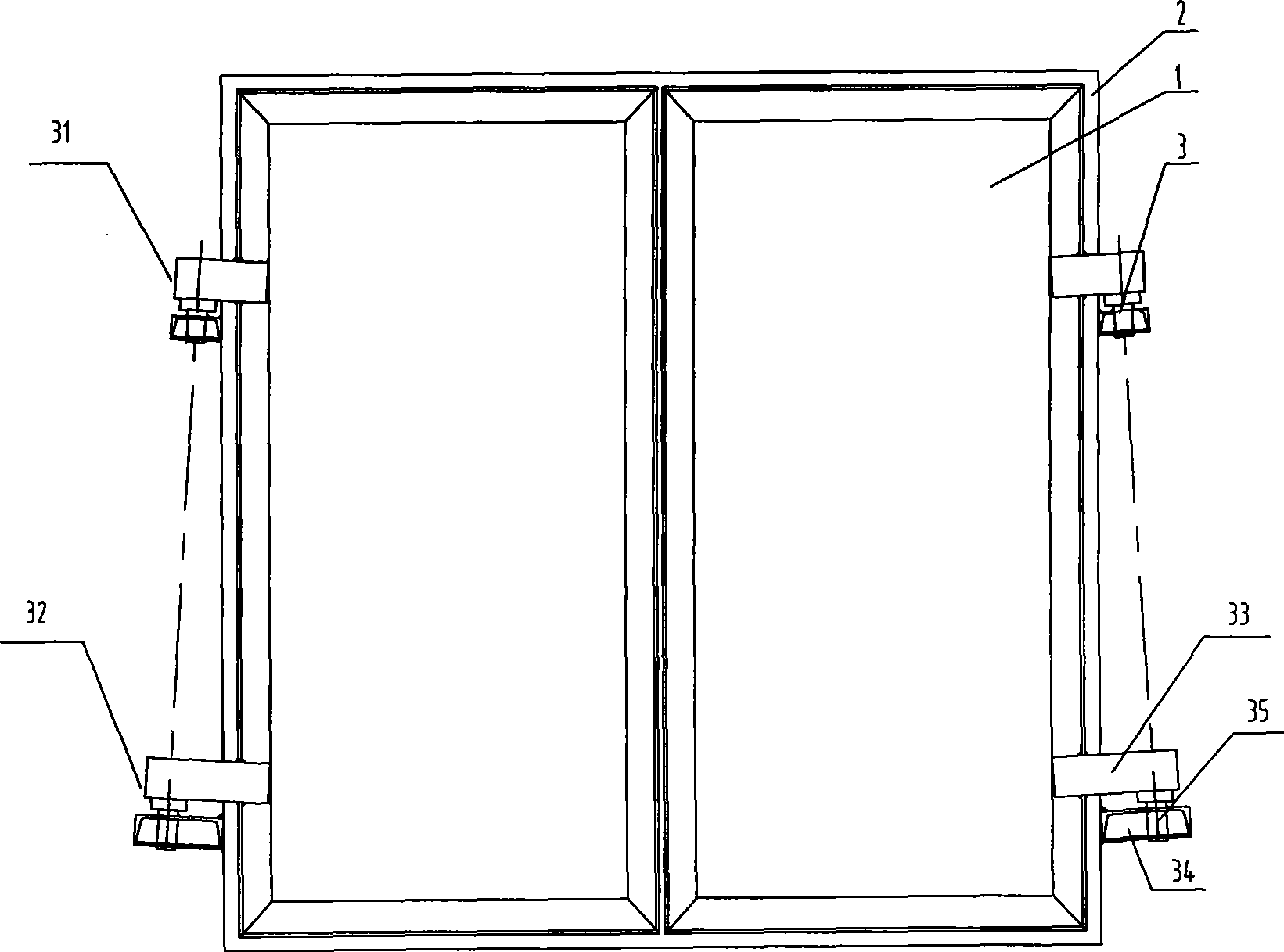

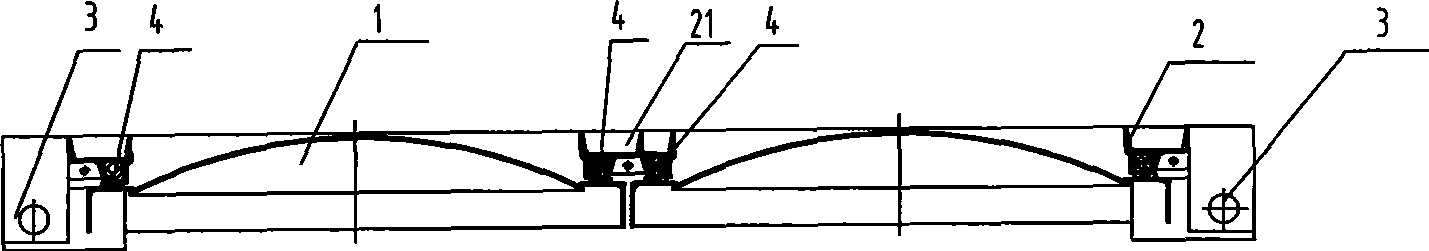

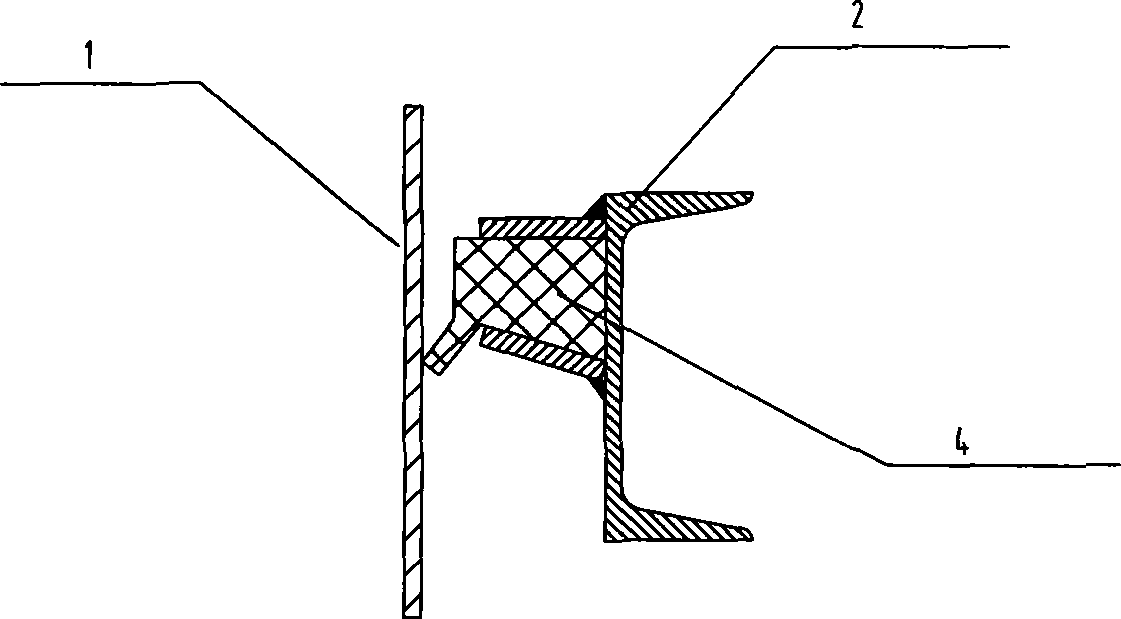

[0019] figure 1 , figure 2 As shown, a free double-sided flip door includes a door leaf 1, a door seat 2 and a hinge assembly 3, the door leaf 1 and the door seat 2 are connected through the hinge assembly 3, and a vertical beam 21 is arranged in the middle of the door seat 2 , the door leaf 1 is arranged on both sides, the door leaf 1 is arranged as an arc surface, the convex surface of the arc surface of the door leaf 1 faces inward, and the concave surface of the arc surface faces outward. When the flap is opened, the water pressure required to activate the flap is relatively small. When the water pressure pushes the flap open, the water flow is ejected from the flaps on both sides like a rush. See Figure 5 shown. With this structure, when the water passes through the valve, the water flow state is streamli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com