Contact type absolute encoder signal collection apparatus and its production method

An absolute encoder and signal acquisition technology, which is applied in the direction of measuring devices, instruments, and conversion sensor output, etc., can solve the problems that the diameter of the chip code disc cannot be reduced, the volume of the encoder is large, and it is difficult to read the signal, so as to achieve a simple structure , reduced size, and low bit error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

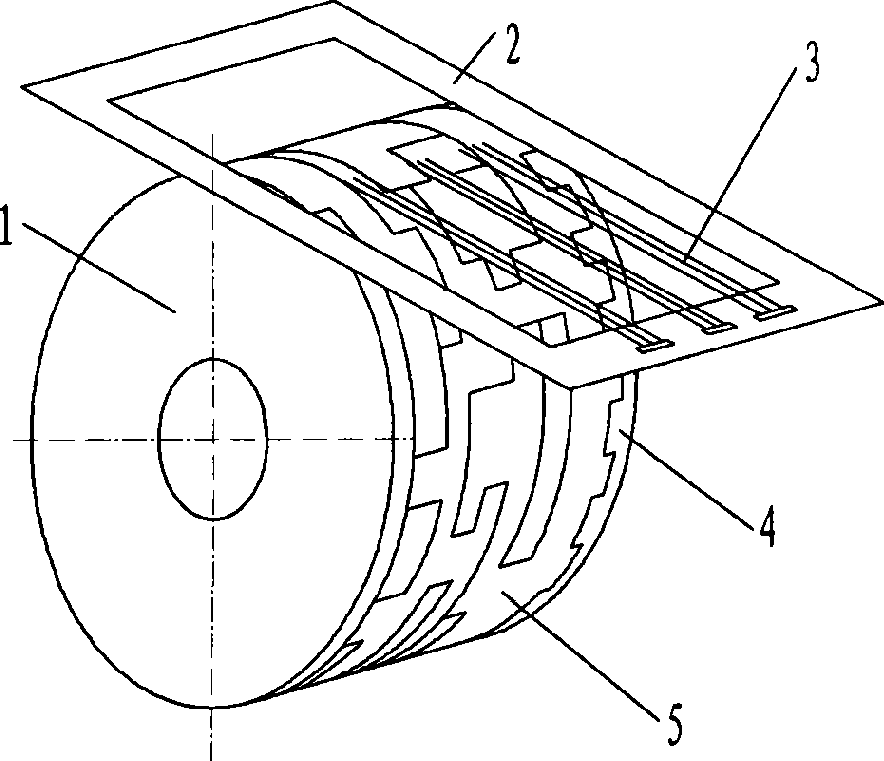

[0014] Embodiment 1: The signal acquisition device includes a coding drum and a V-shaped platinum-iridium wire brush head, and the contact point of the V-shaped brush head is overlapped on the coding drum wheel and can slide on the drum wheel.

[0015] The coding drum is a cylinder with a shaft in the center, which is formed by stacking multiple coding sheets; the surface of the cylinder is smooth, and on the working area of the outer wall of the cylinder, there are conductive parts 5 arranged according to the coding law and the non-conductive part 4, the two parts are arranged according to the coding law; the surface of the cylinder is engraved with "V" grooves, and the "V" grooves are distributed on the outer wall of the cylinder, and each "V" groove is connected from the beginning to the end. Next, the position of the "V"-shaped groove is in elastic contact with the position of the platinum-iridium wire V-shaped brush head.

[0016] The signal collection device includes a...

Embodiment 2

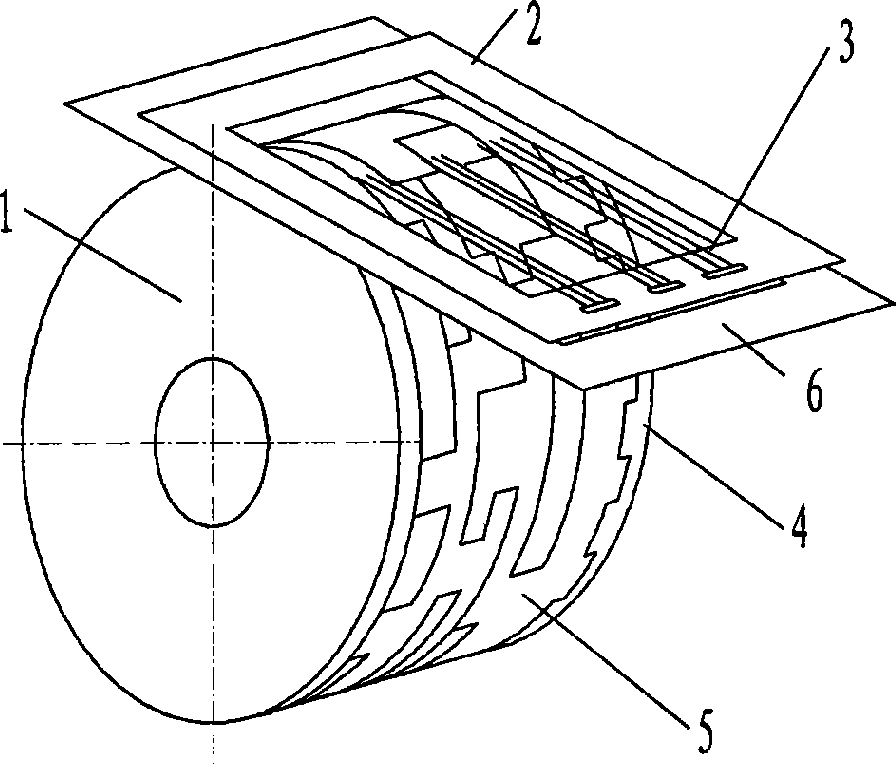

[0019] Embodiment 2: The signal acquisition device includes a coding drum and a V-shaped platinum-iridium wire brush head, and the contact point of the V-shaped brush head is lapped on the coding drum wheel.

[0020] The coding drum 1 is a cylinder with a smooth surface. Conductive parts and non-conductive parts, conductors 5 and non-conductors 4 are arranged according to coding rules on the outer wall of the cylinder.

[0021] The surface of the cylinder is arranged with code tracks according to the number of bits of the encoder, and there are three "V"-shaped grooves on each code track, each "V"-shaped groove is connected end to end, and the position of the "V"-shaped groove is in line with the brush filament The location of the brush head contacts corresponds.

[0022] The signal acquisition device includes a brush holder bracket 6, a brush holder 2 and a brush head 3, the other end of the brush head is connected to the brush holder, and the brush holder is connected to the...

Embodiment 3

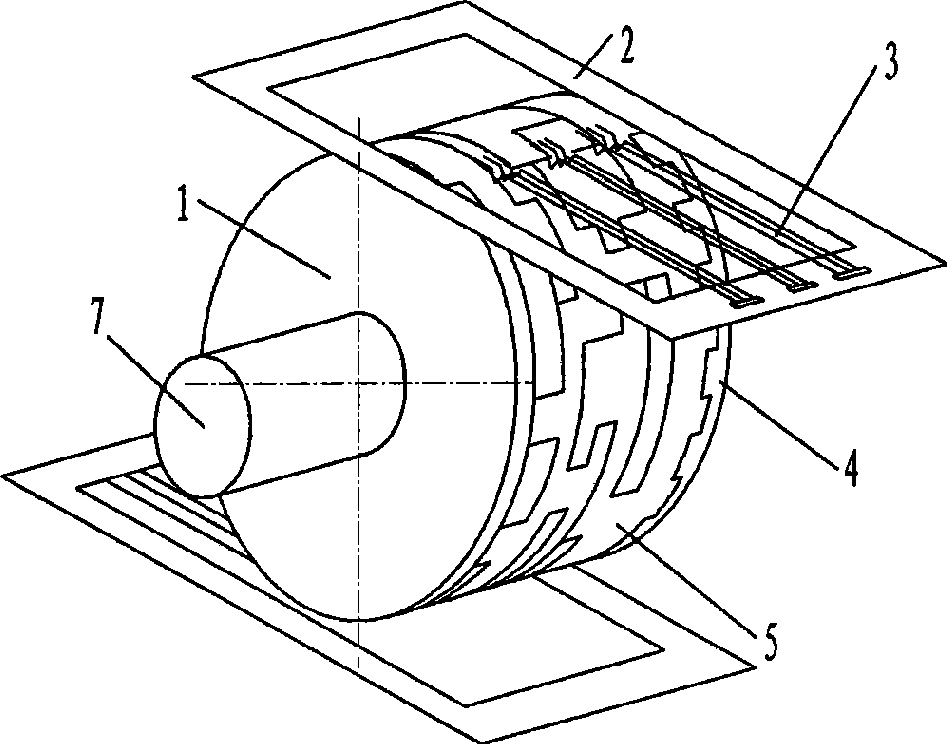

[0025] Embodiment 3: The signal acquisition device includes a coding drum and a platinum-iridium wire V-shaped brush head, and the contacts of the brush head are lapped on the coding drum wheel.

[0026] The coding drum is a cylinder, and on the outer wall of the cylinder, there are conductive parts and non-conductive parts arranged according to the coding rules; there are "V"-shaped grooves on the surface of the cylinder, and the "V"-shaped grooves are distributed On the outer wall of the cylinder, each "V"-shaped groove is connected end to end, and the position of the "V"-shaped groove corresponds to the position of the contact point of the platinum-iridium wire brush head.

[0027] The signal acquisition device includes a brush holder bracket, a brush holder and a brush head, the other end of the brush head is connected to the brush holder, and the brush holder is connected to the brush holder bracket.

[0028] The polymer insulating filler is methyl methacrylate.

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com