Light controlled vacuum switch module

A vacuum switch and vacuum interrupter technology, applied in the field of power high-voltage switches, can solve the problems of insurmountable insulation of long vacuum gaps, complex insulation structures, difficult direct control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

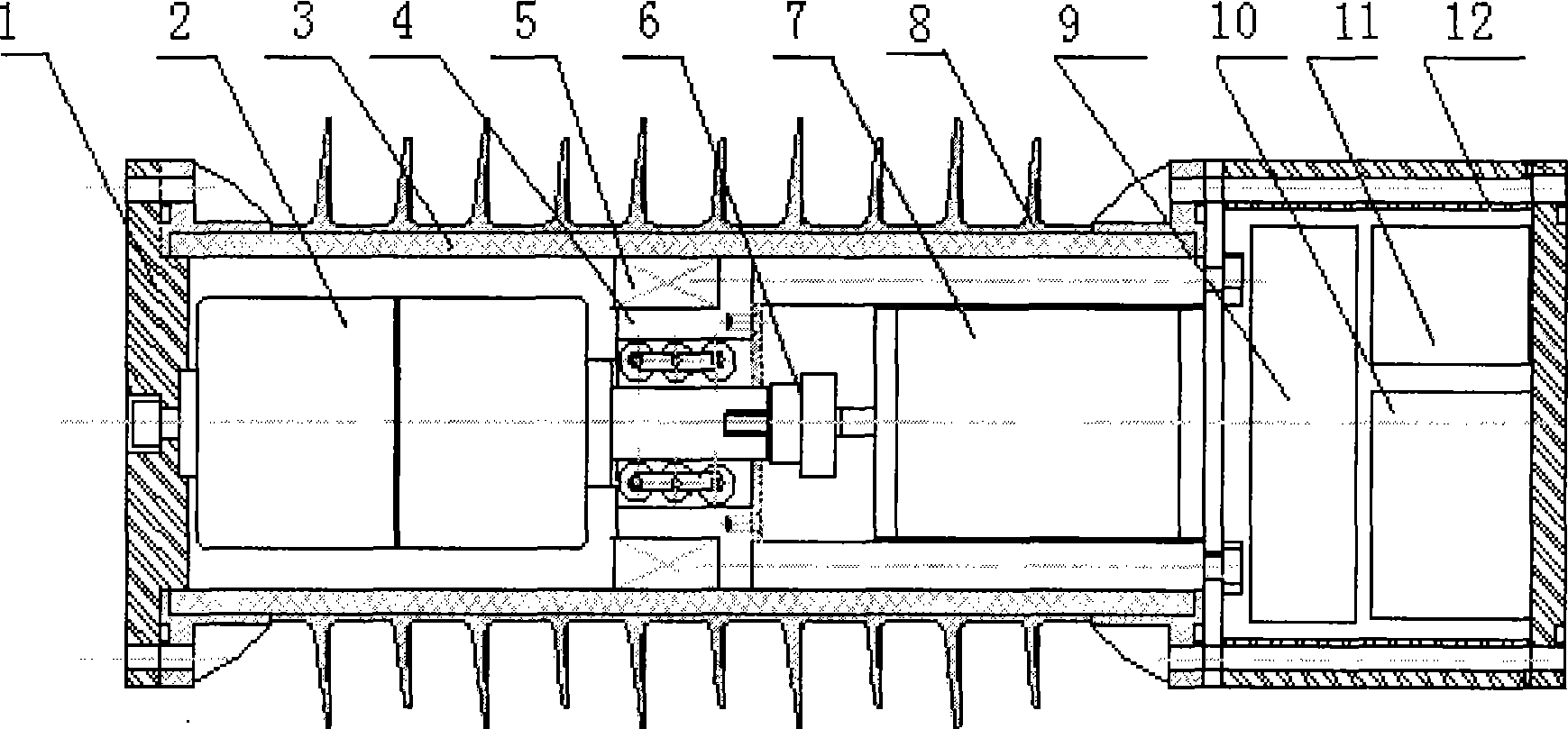

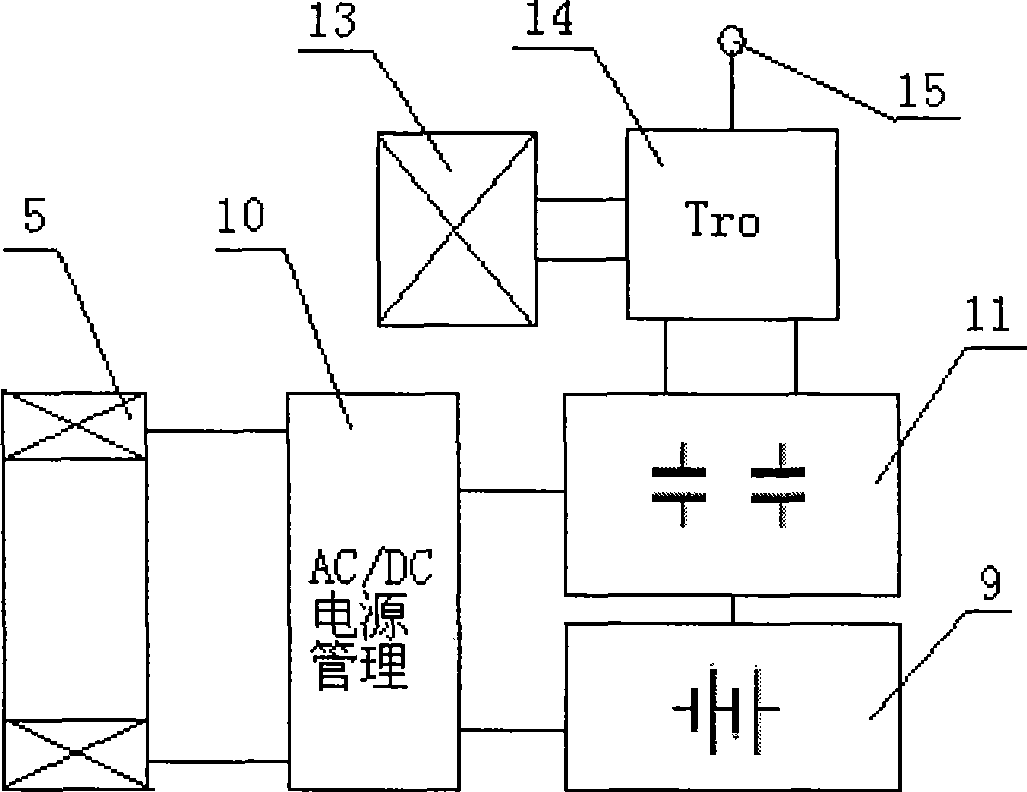

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0015] The secondary current induced by the induction power coil 5 with iron core is sent to the wide-range AC / DC power management board 10 and the storage battery 9; the induction power coil 5, the power management board 10 and the storage battery 9 are general-purpose devices and are sequentially connected to form a self-contained power supply , to charge the capacitor 11; the operating mechanism 7 is a permanent magnet mechanism, and when the excitation coil 13 of the mechanism is passed with currents in different directions, the closing and opening operations of the mechanism can be completed; the control signal is connected to the light-controlled power electronics by the input optical interface 15 The switch 14 releases the electric energy in the capacitor 11 to the excitation coil 13 of the mechanism to complete the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com