Electric system tide optimization method for high-efficient processing complex electric control appliance

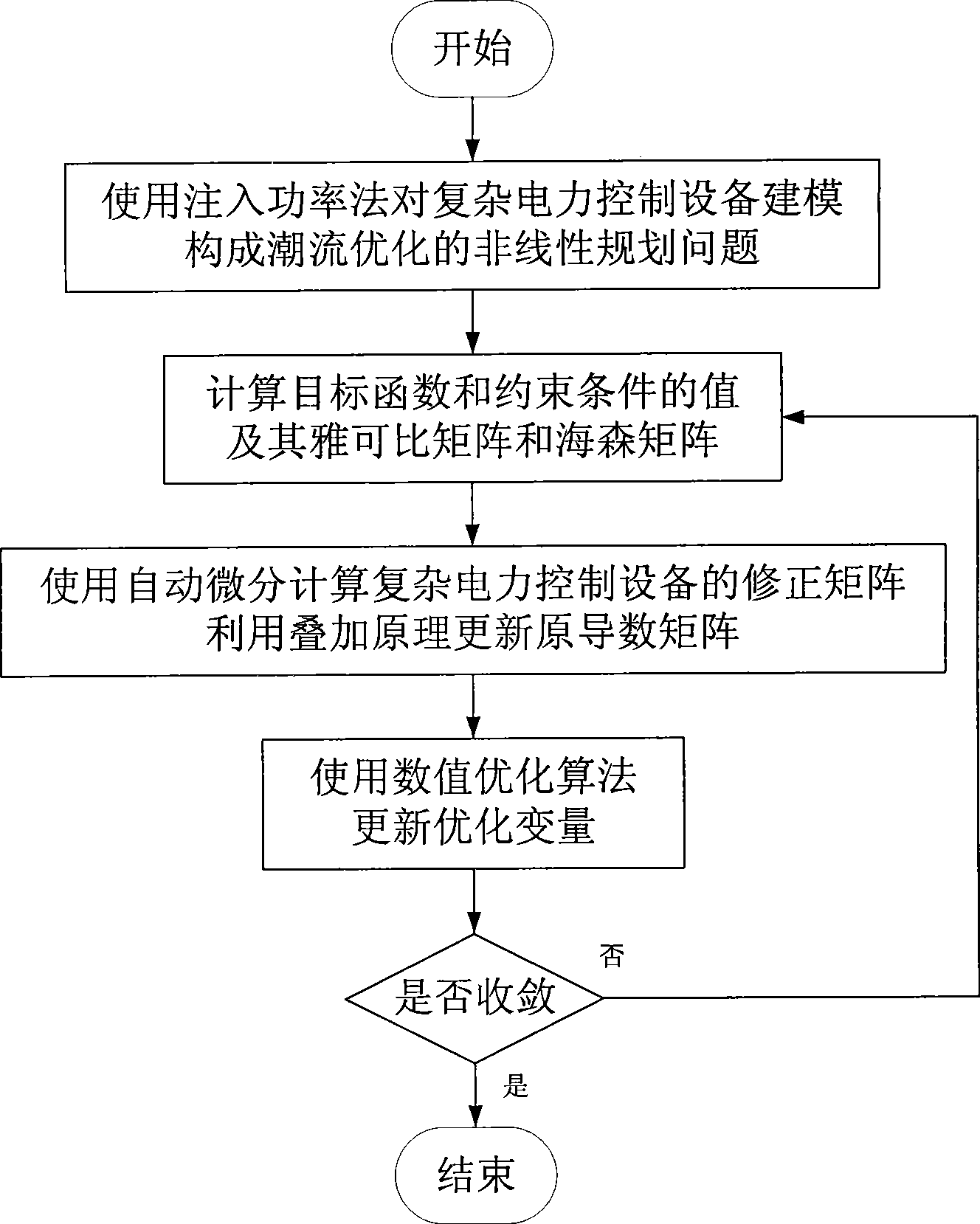

A technology of power control and optimization method, which is applied in the direction of electrical components, circuit devices, AC network circuits, etc., can solve problems such as insufficient program flexibility and scalability, difficulty in derivation and implementation, and complex calculation formulas, so as to improve maintainability , avoid formula derivation and implementation, and improve the effect of calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

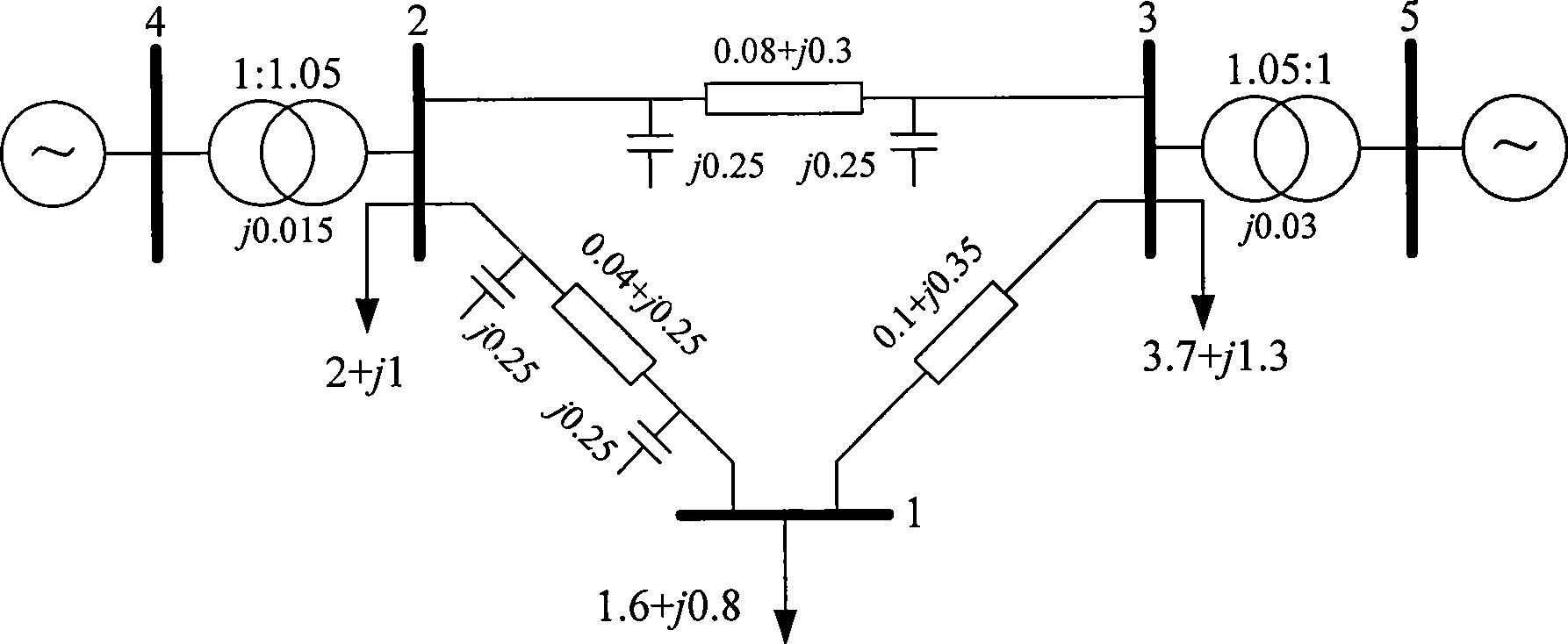

[0052] consider as figure 2 In the example power system shown, if other complex power control devices are not considered, the steps of power flow optimization using the interior point method are as follows:

[0053] Calculate the grid admittance matrix (the results are omitted), and set the optimization variable of the power flow optimization problem as x, which includes [P G , Q G , V e , V f , X c ], where P G and Q G are the active output and reactive output of the generator respectively, V e and V f are the real and imaginary parts of the voltage at each node, X c Customize the control variables of the model for other users in the system.

[0054] The objective function is set as the minimum fuel cost of system power generation (1), where α is the economic coefficient of each generator.

[0055] f ( x ) = Σ ( α i ...

Embodiment 2

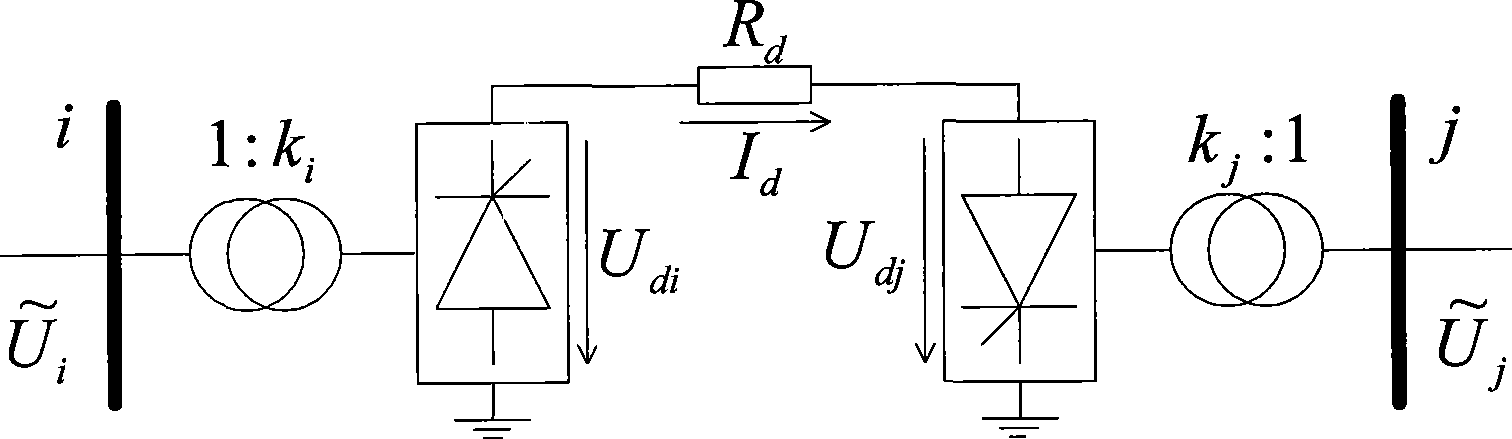

[0105] This embodiment uses the same objective function, constraints and numerical optimization algorithm as in Embodiment 1, and considers multiple groups of test power systems as shown in Table 3, which involve static var compensators (Static Var Compensators, SVC) and Thyristor Controlled Series Capacitor (TCSC) are three complex power control devices.

[0106] Table 3 Summary of Test System

[0107]

[0108] In order to compare the performance of the method proposed by the present invention, the following two reference methods are set for comparison.

[0109] 1. Manual programming: the correction matrix of complex power control equipment is realized by manual programming;

[0110] 2. Automatic differentiation: All Jacobian matrices and Hessian matrices are calculated using automatic differentiation.

[0111] Table 4 shows the calculation efficiency comparison between the method proposed by the present invention and the above two groups of comparison methods.

[0112]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com